Product Finder

Filters:

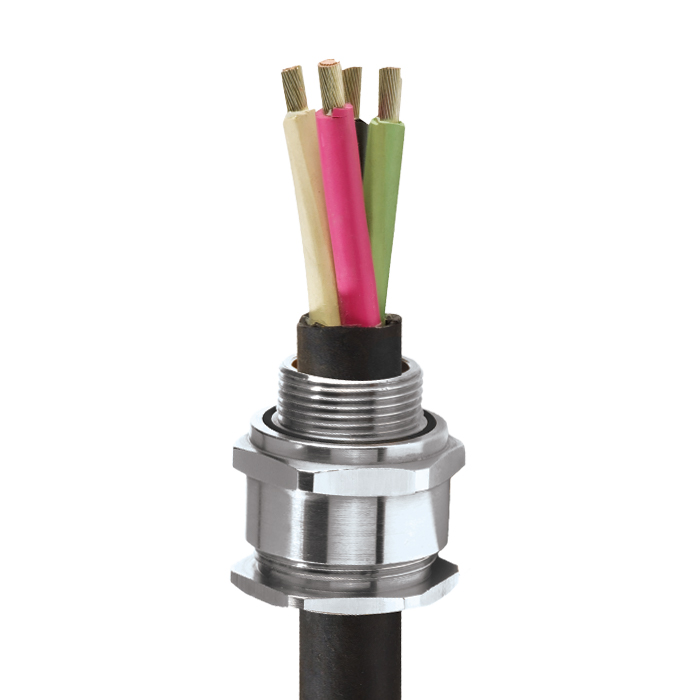

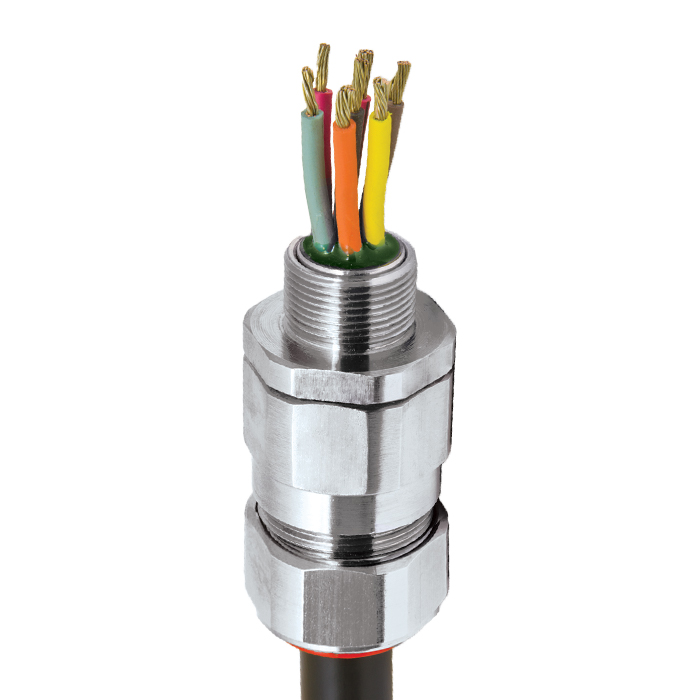

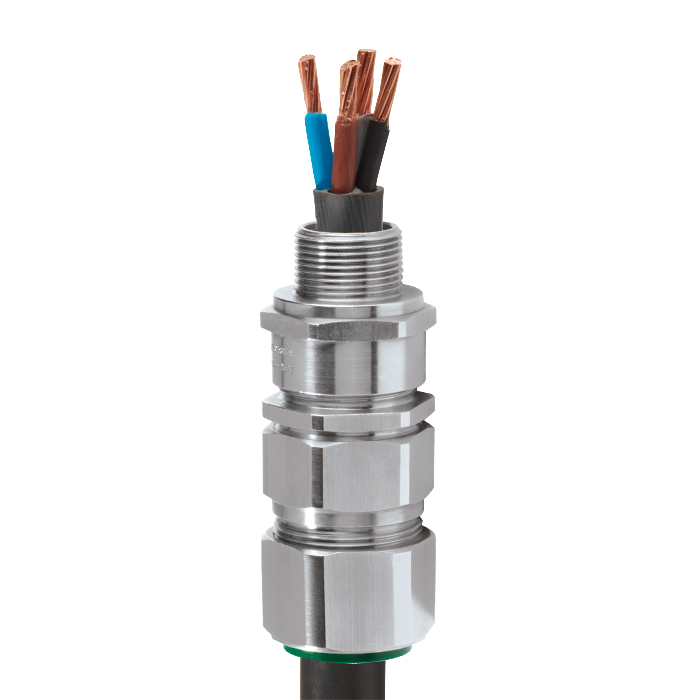

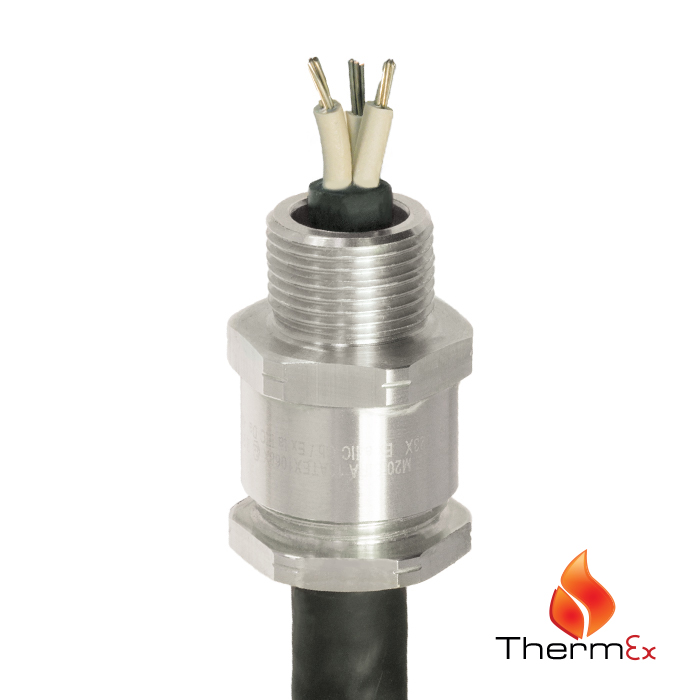

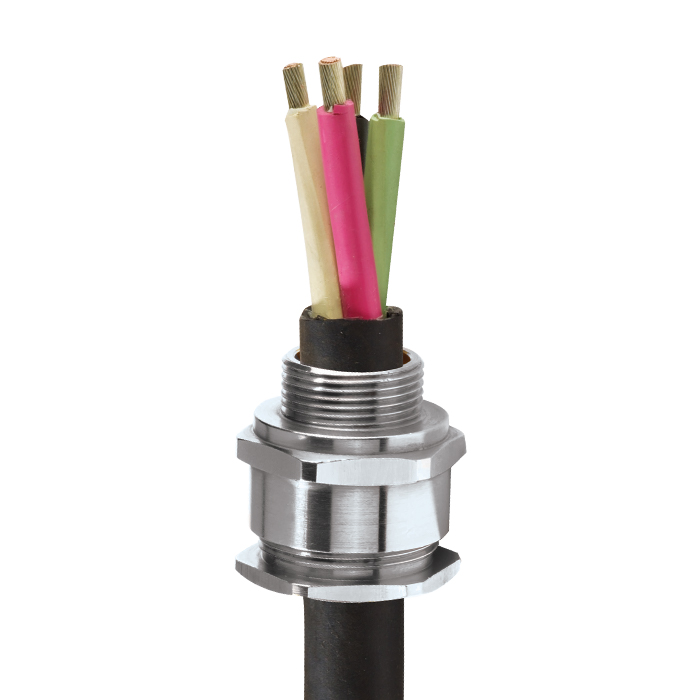

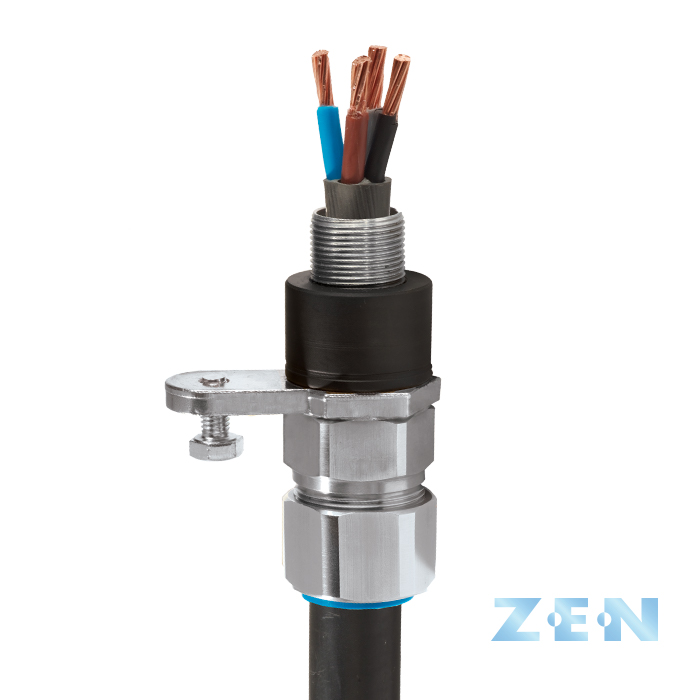

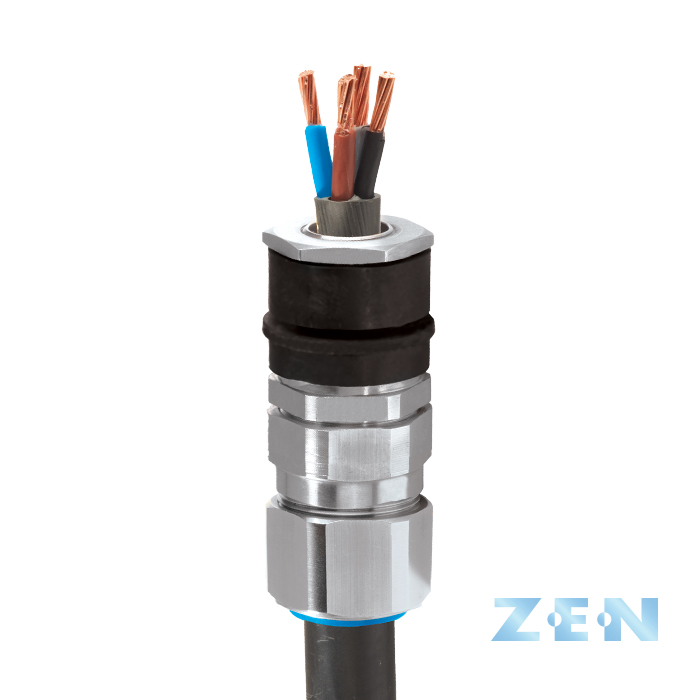

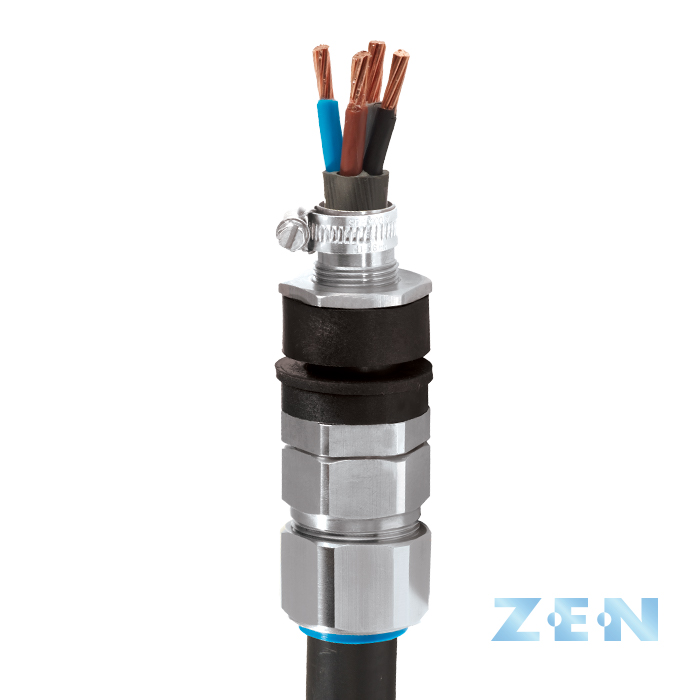

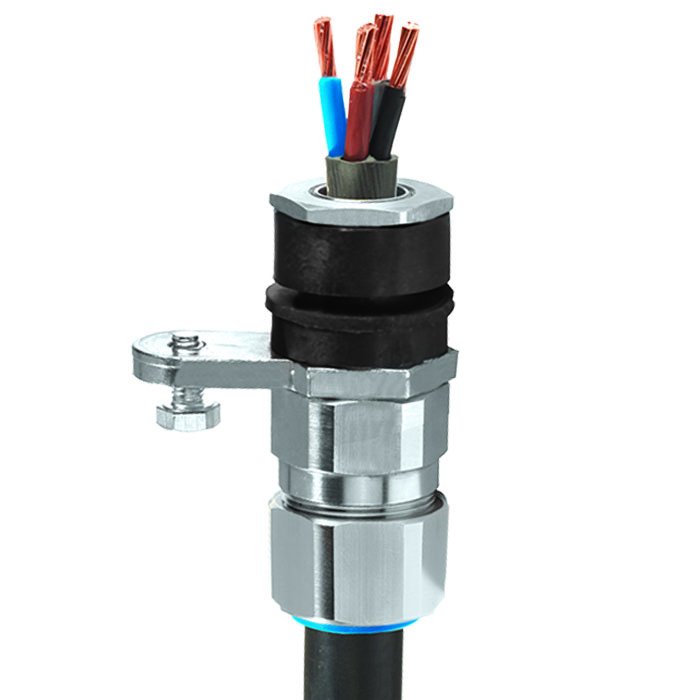

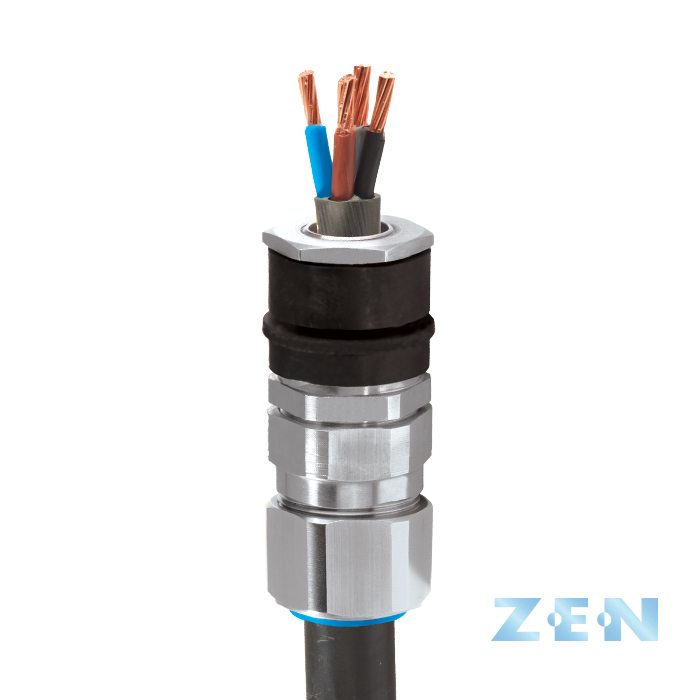

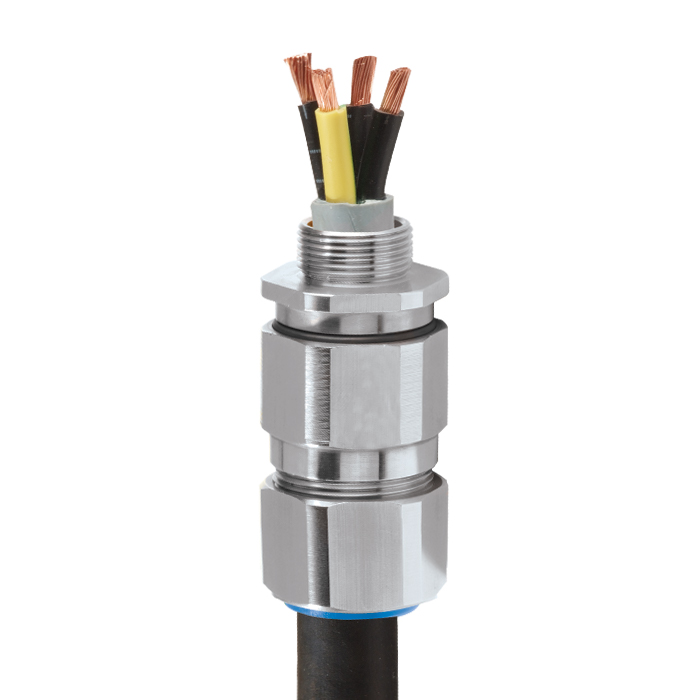

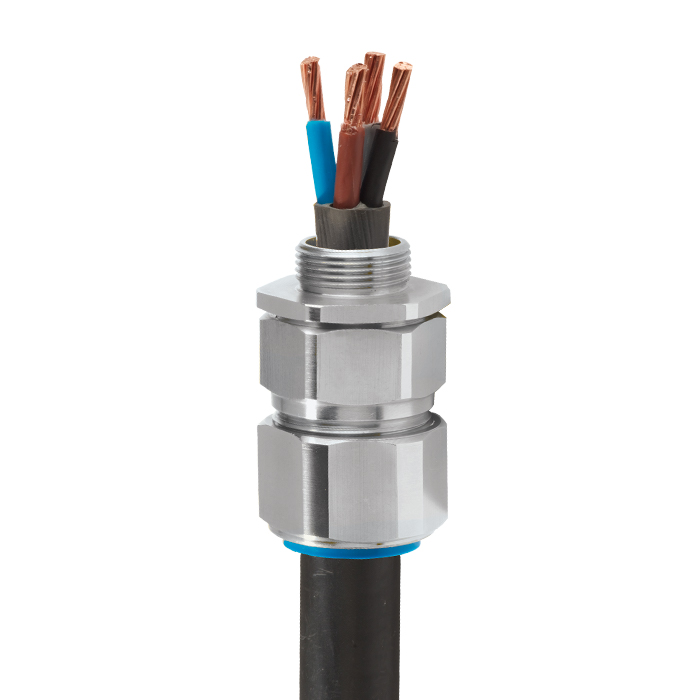

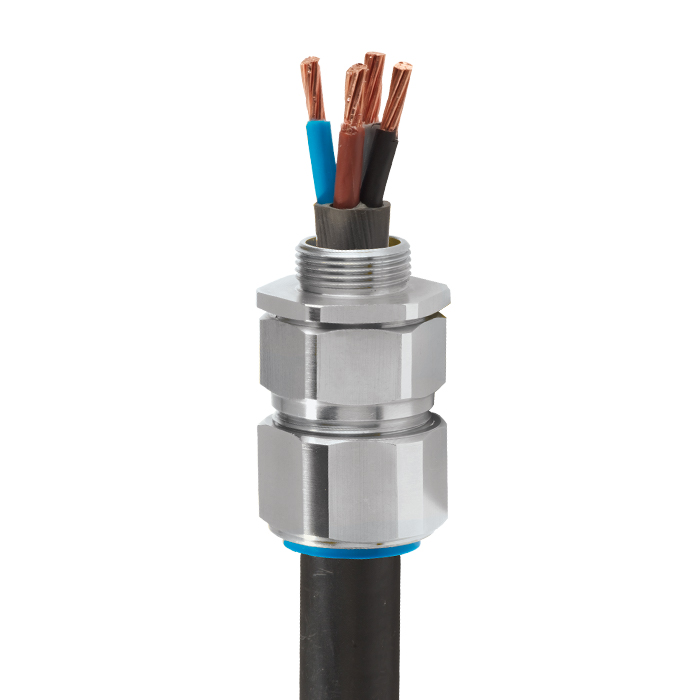

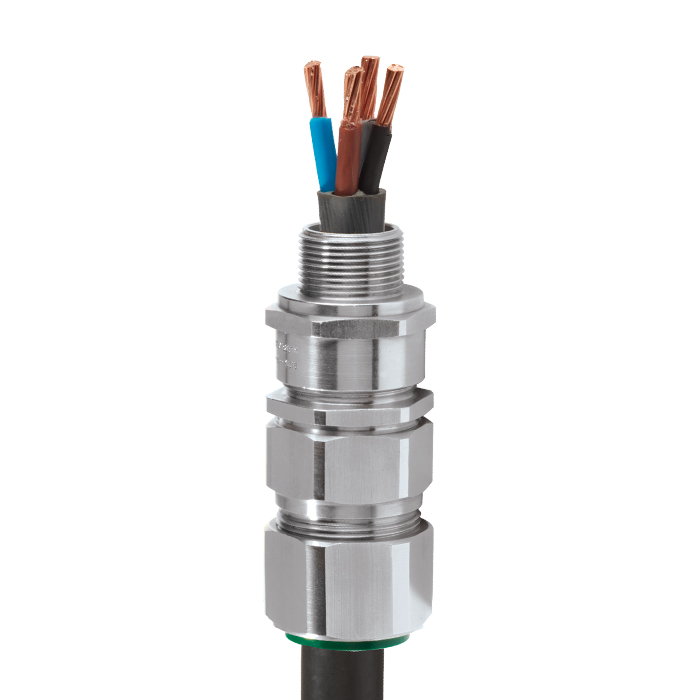

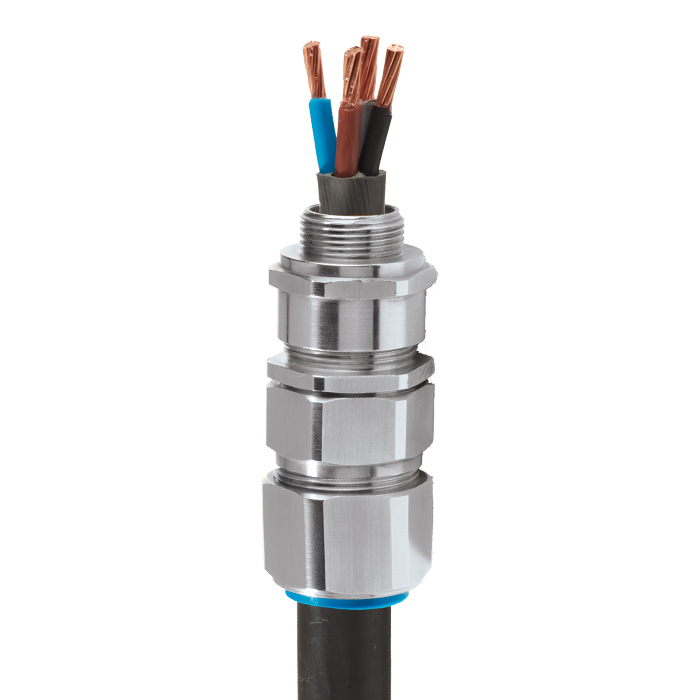

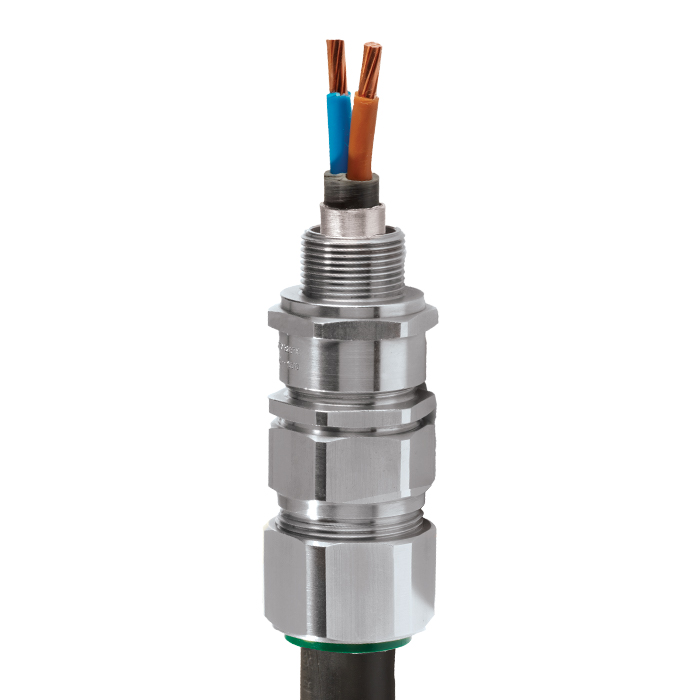

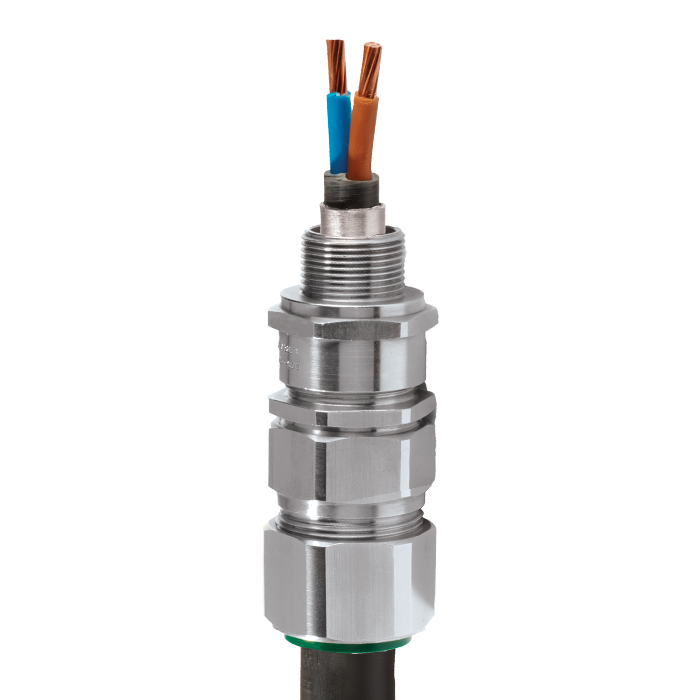

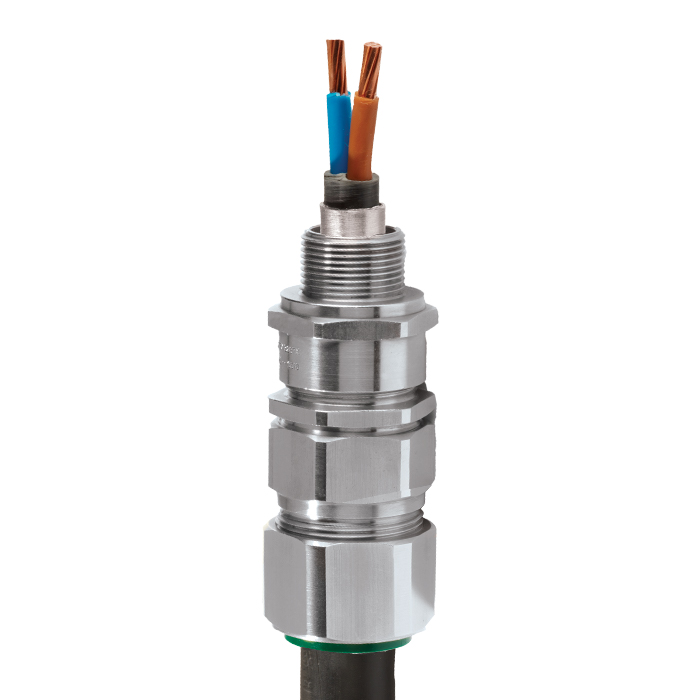

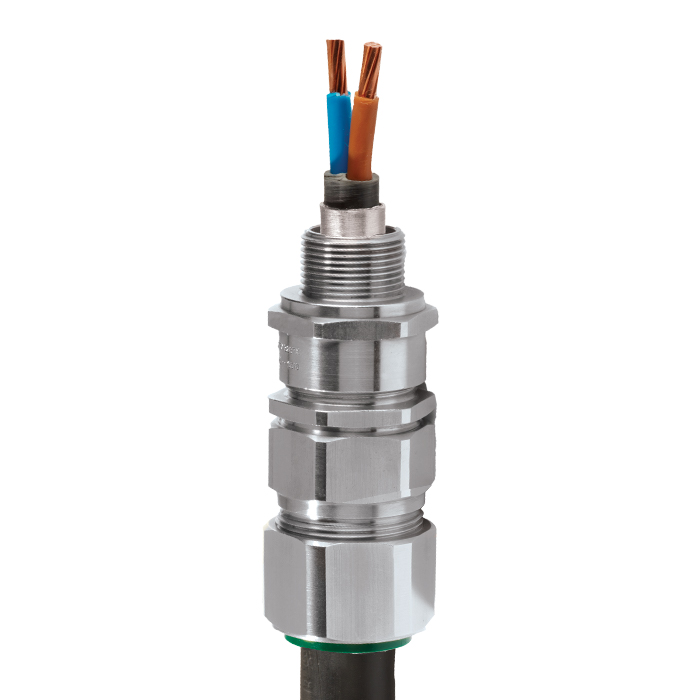

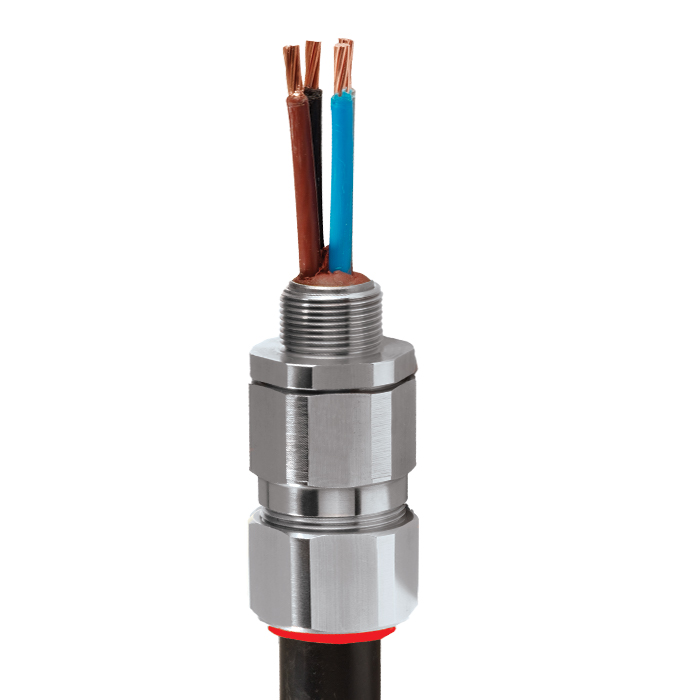

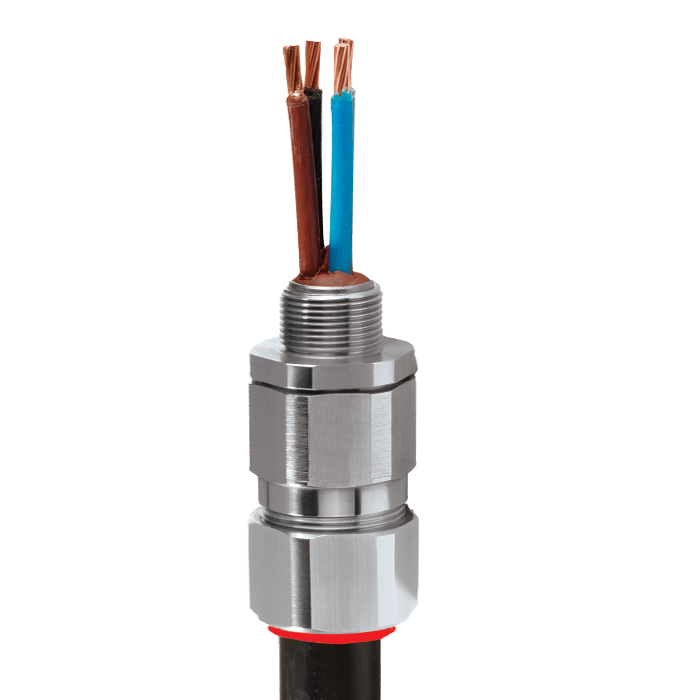

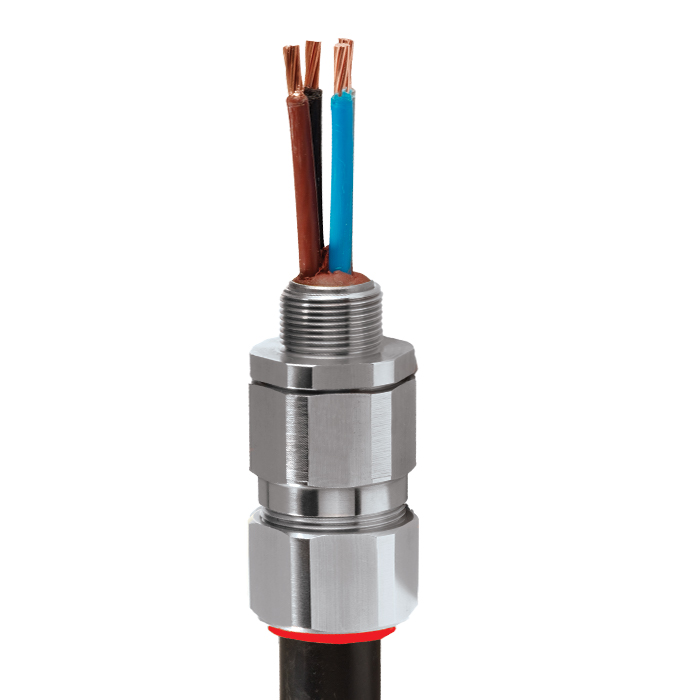

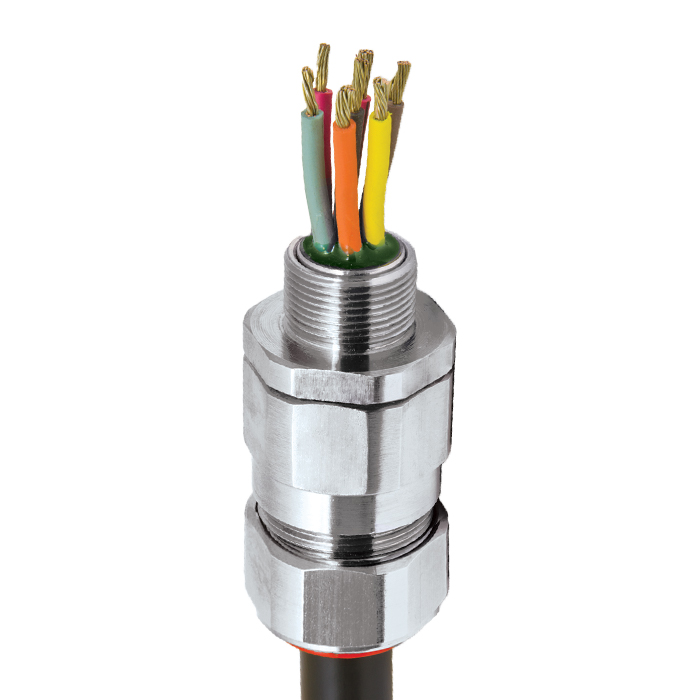

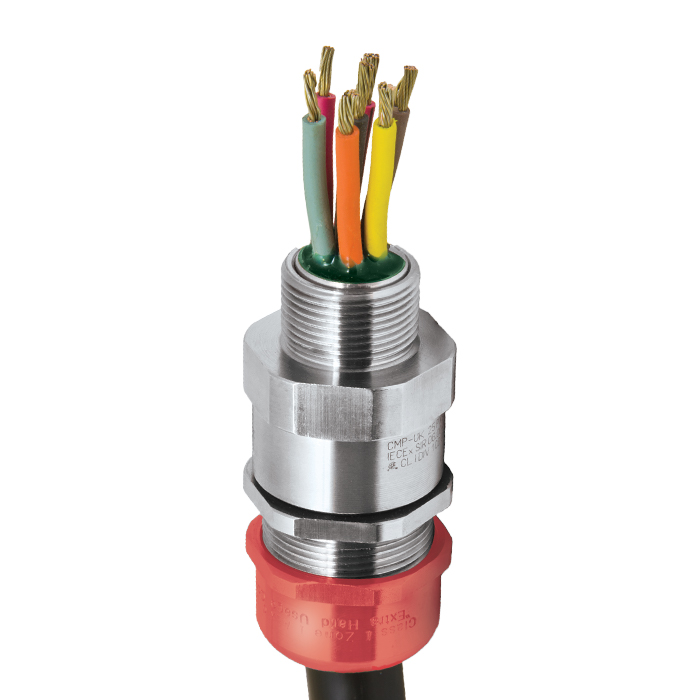

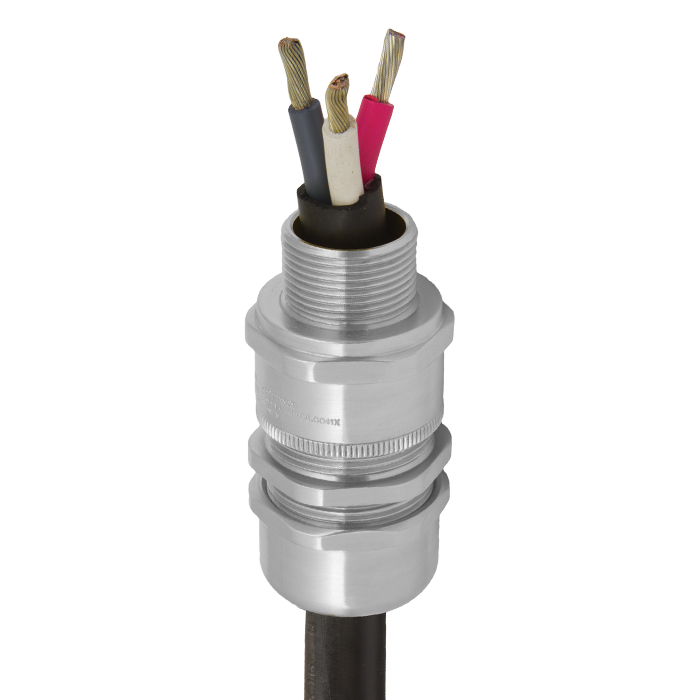

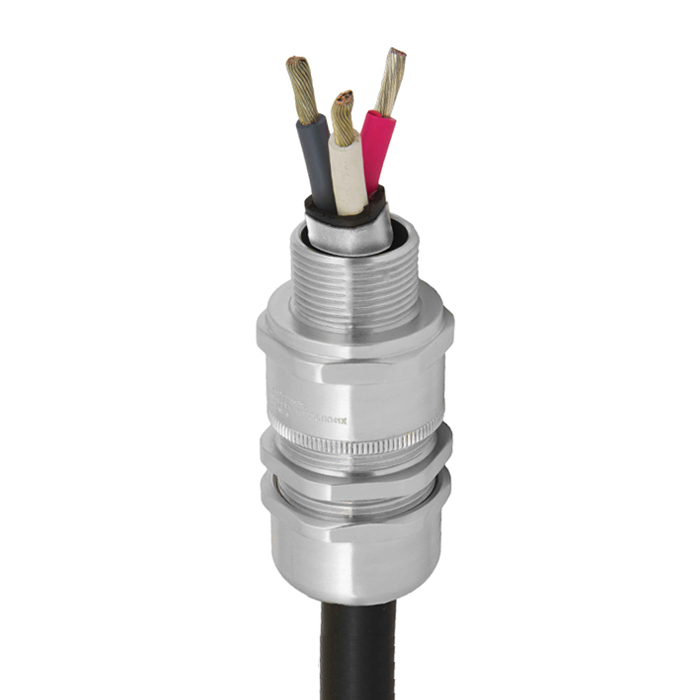

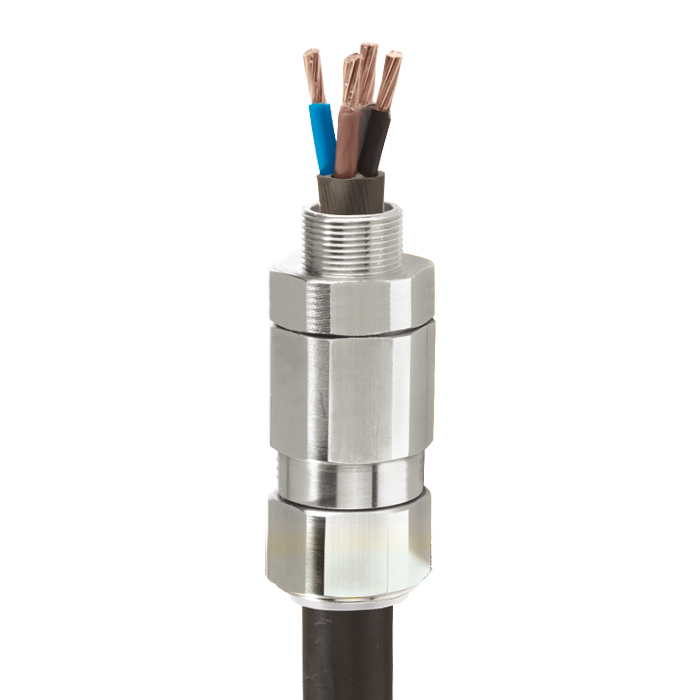

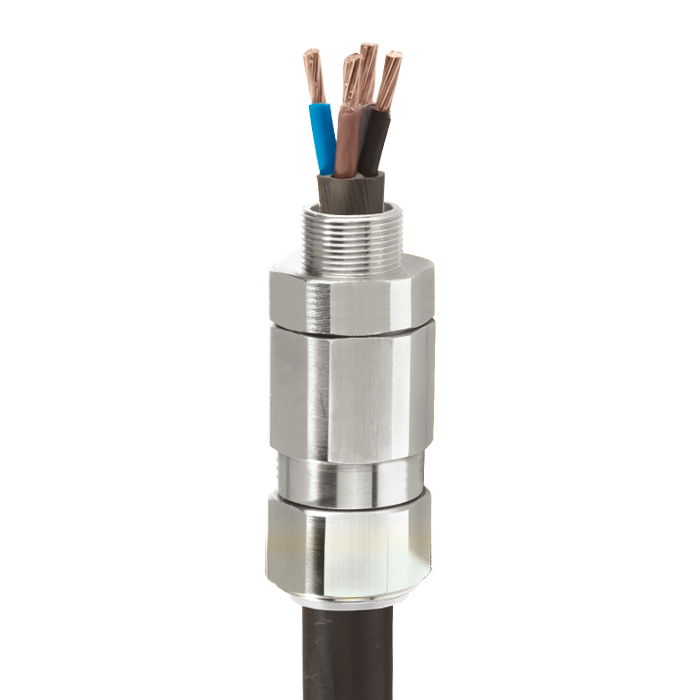

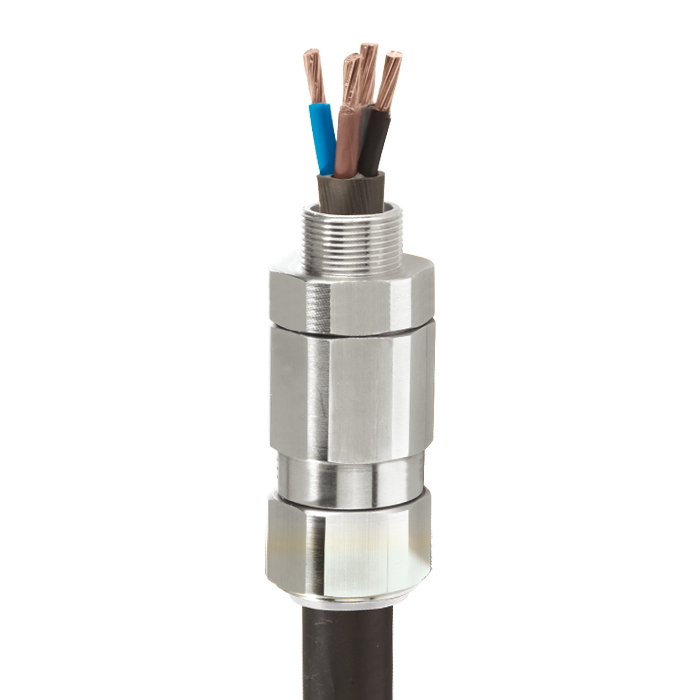

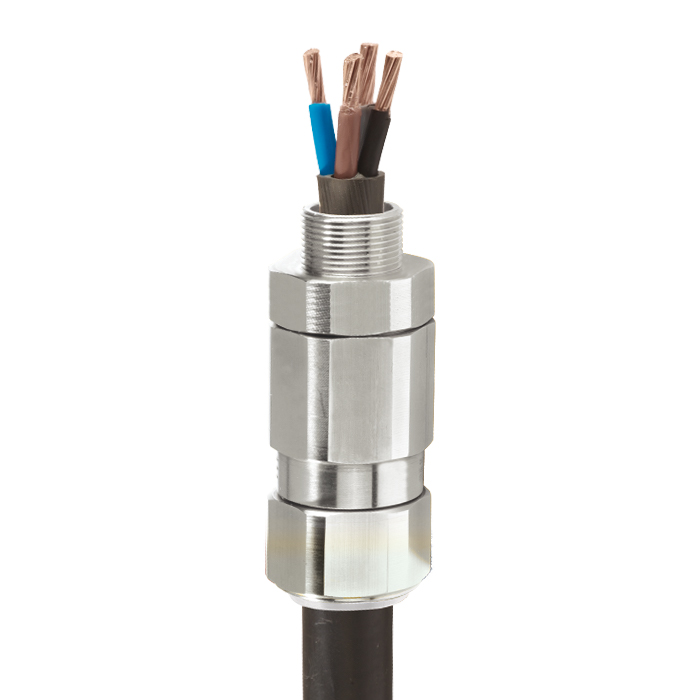

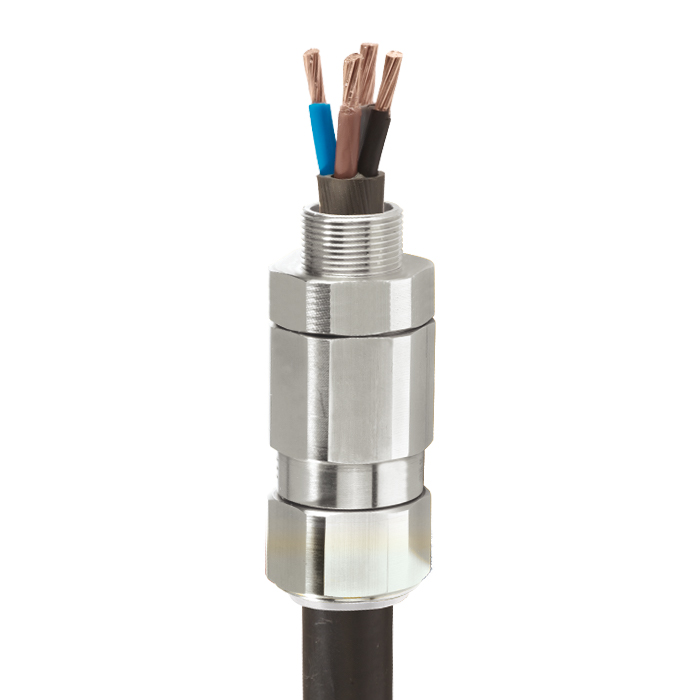

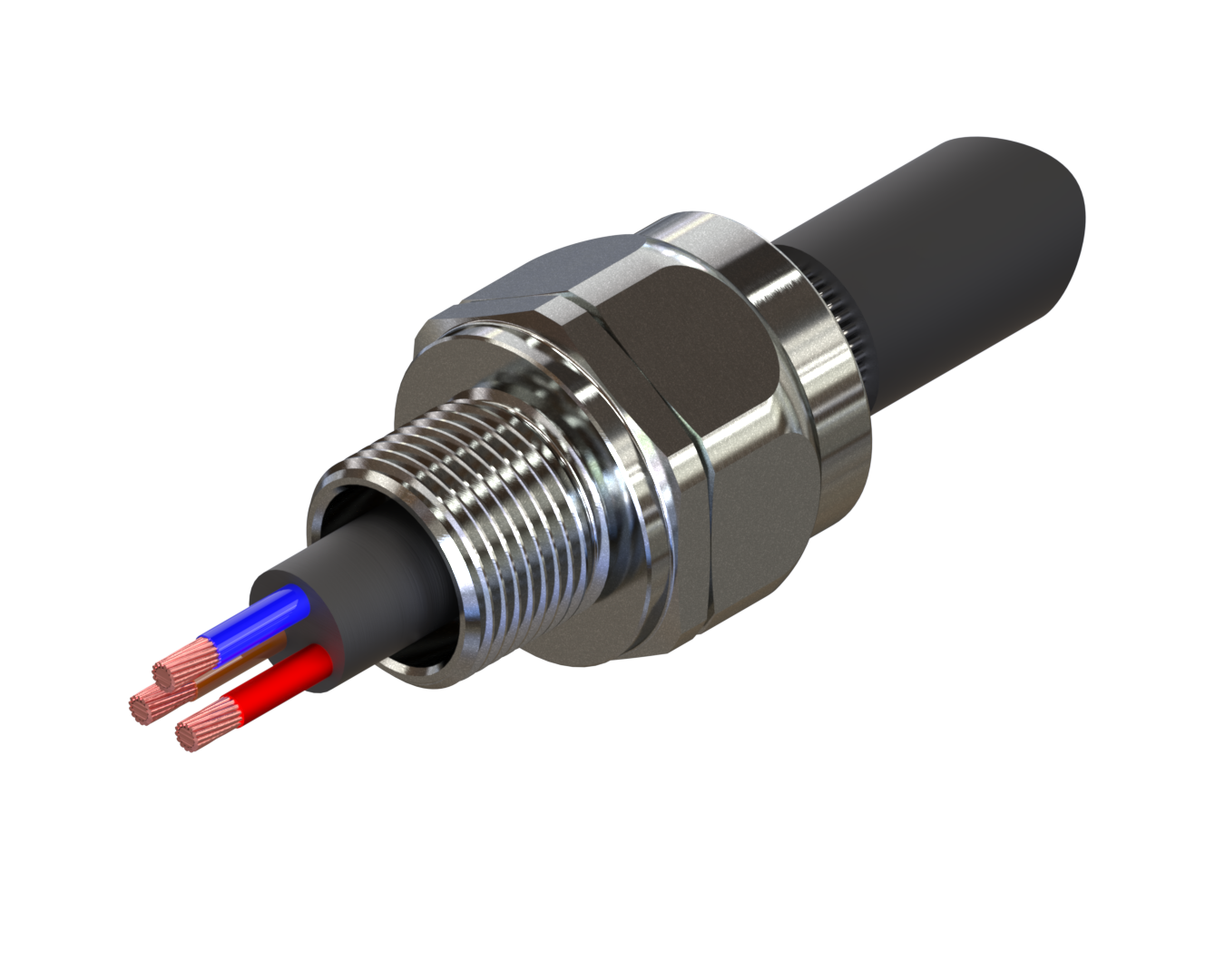

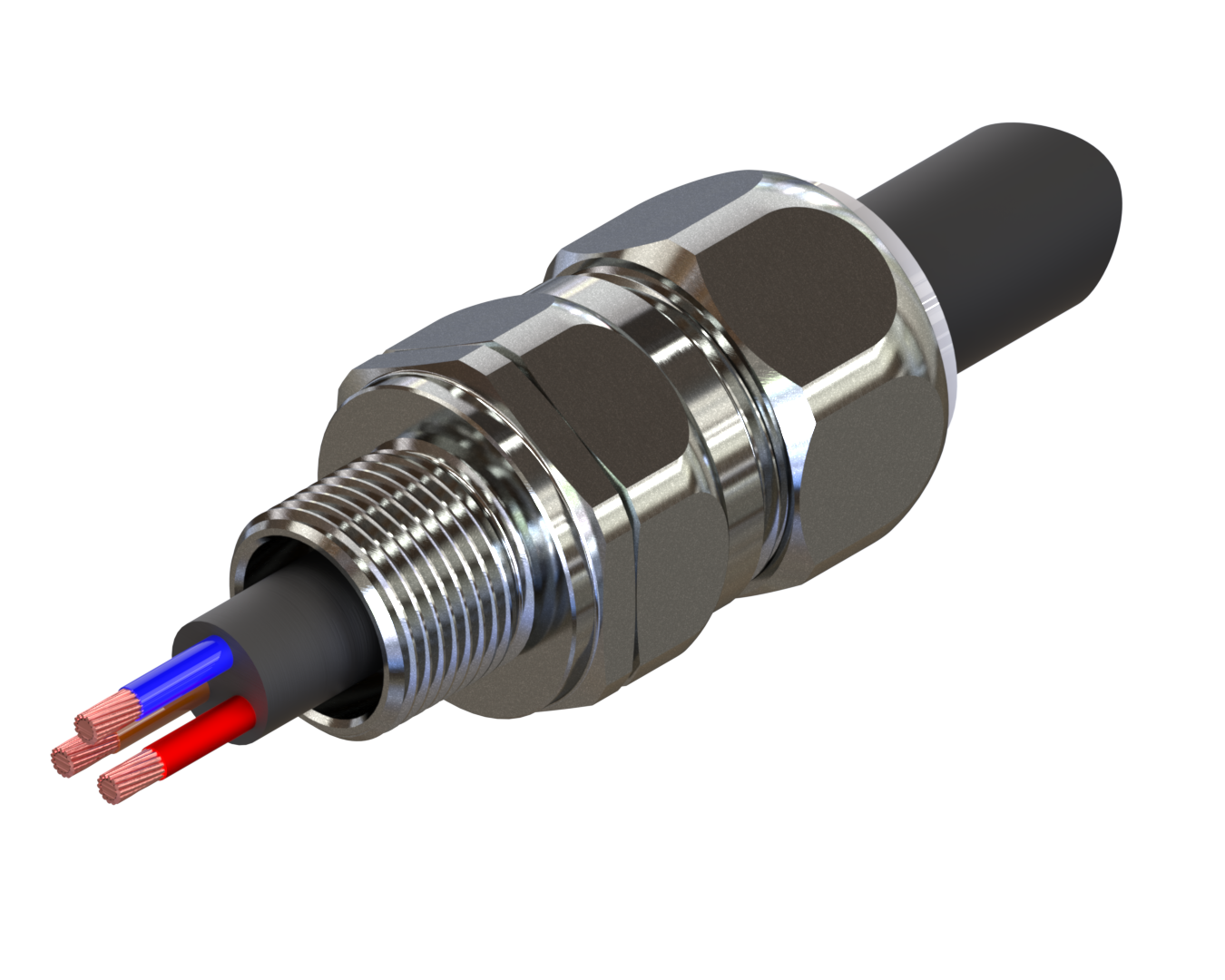

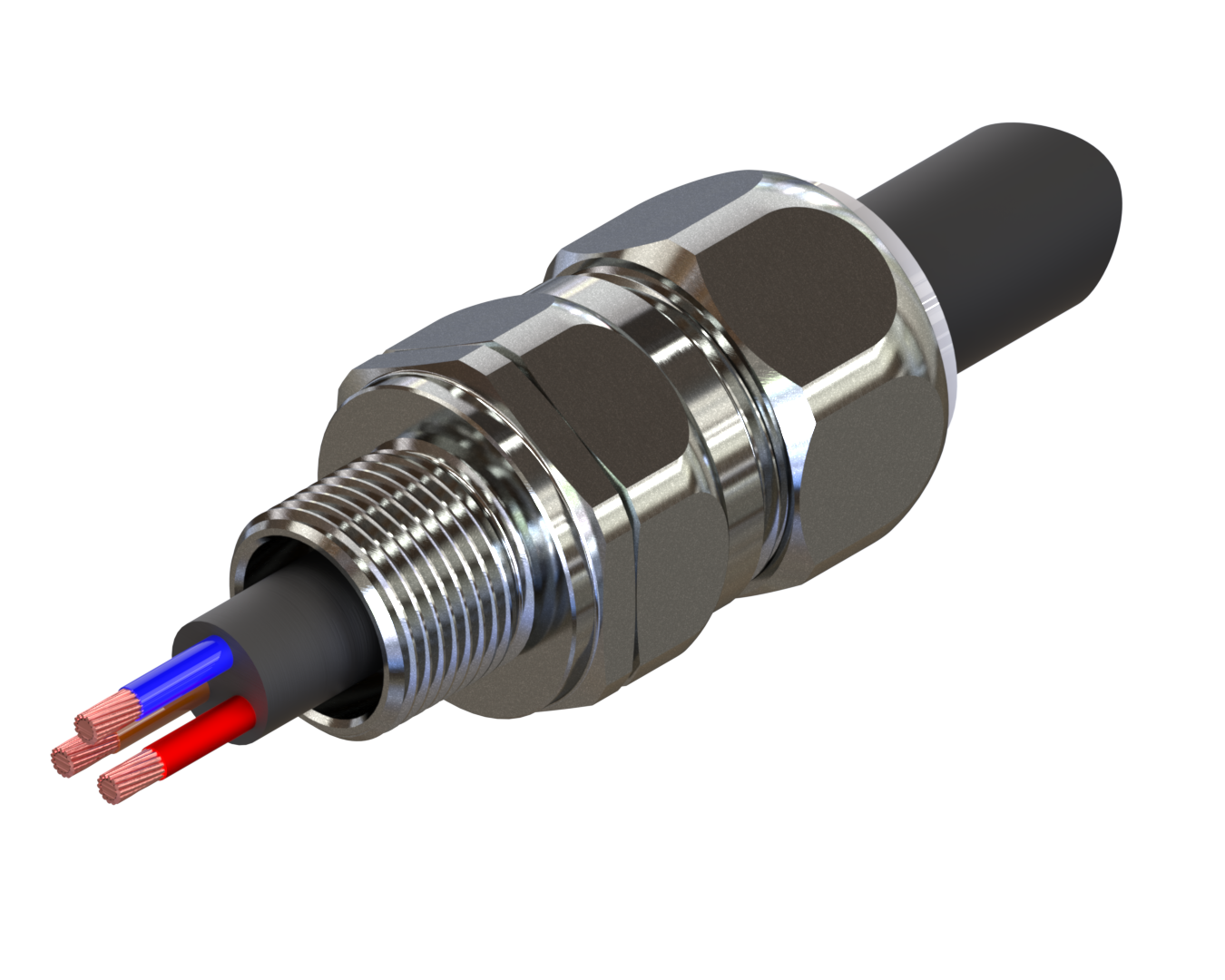

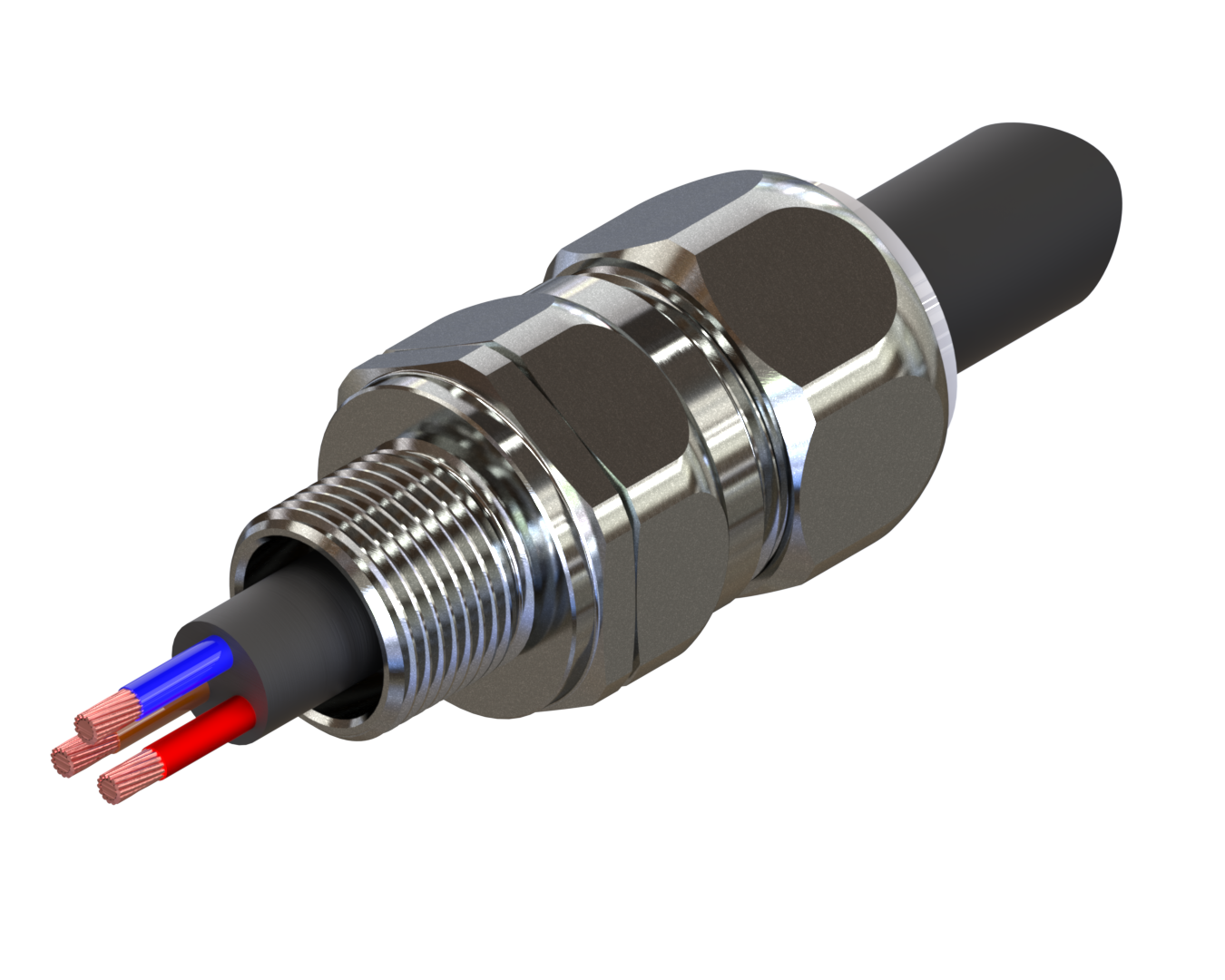

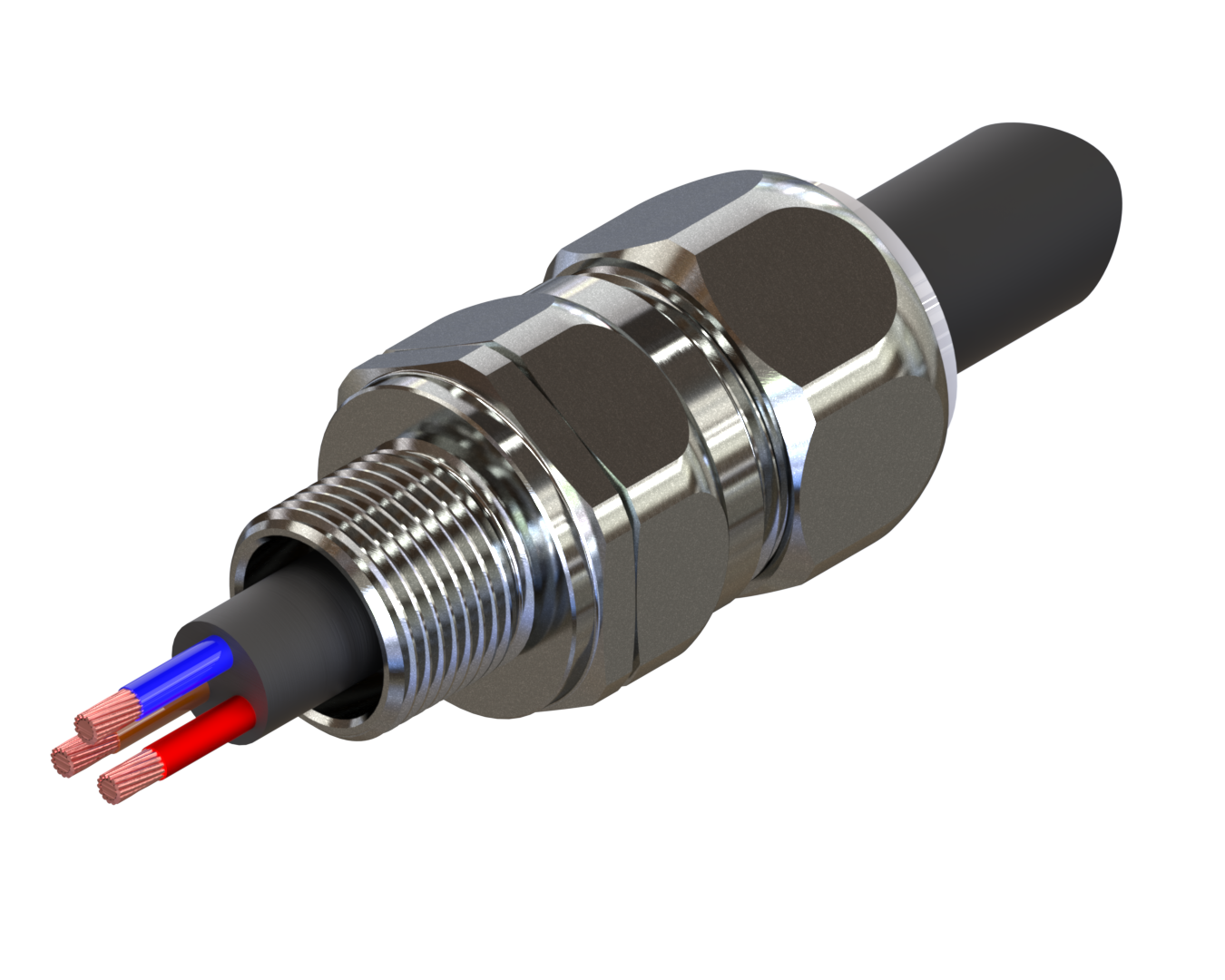

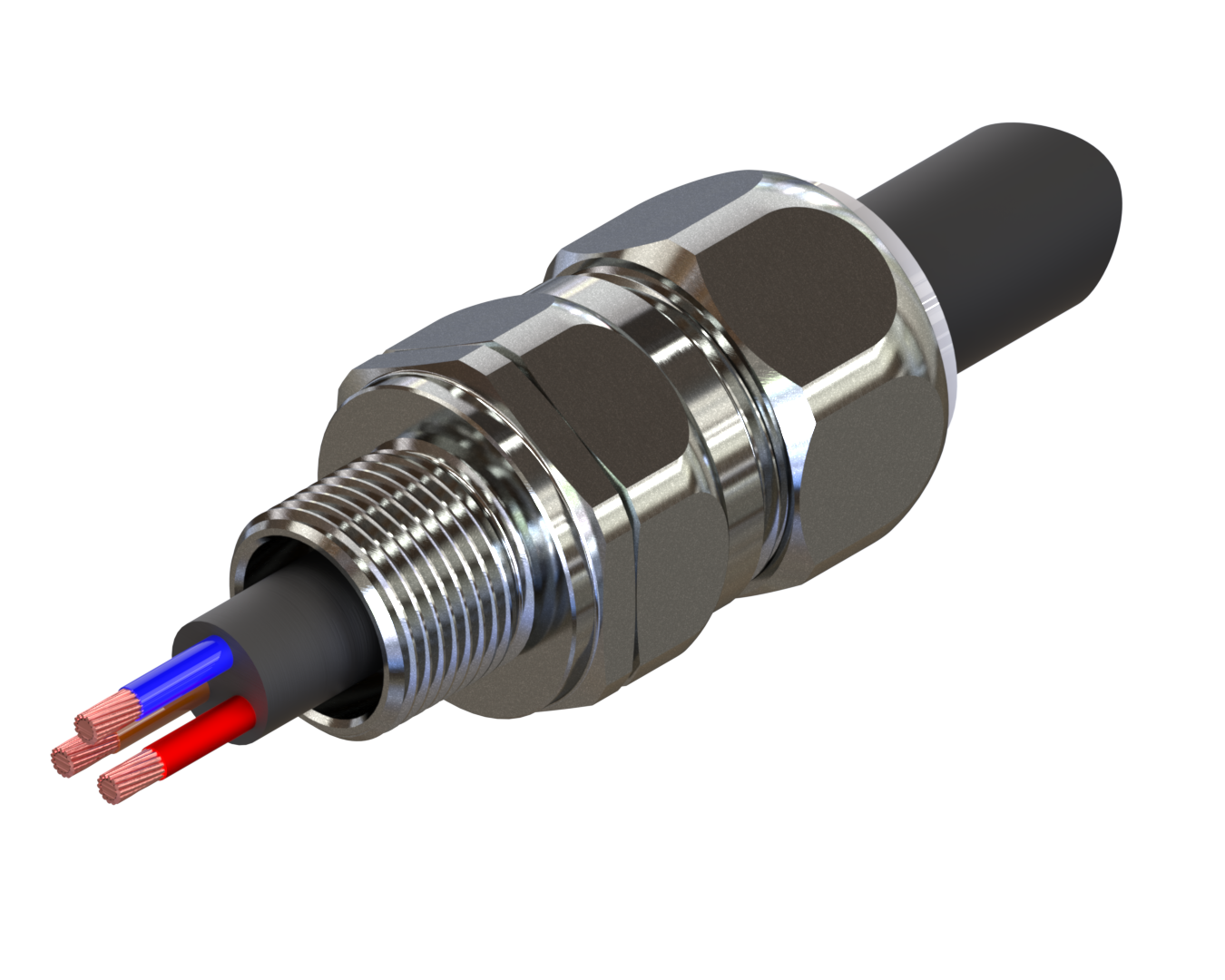

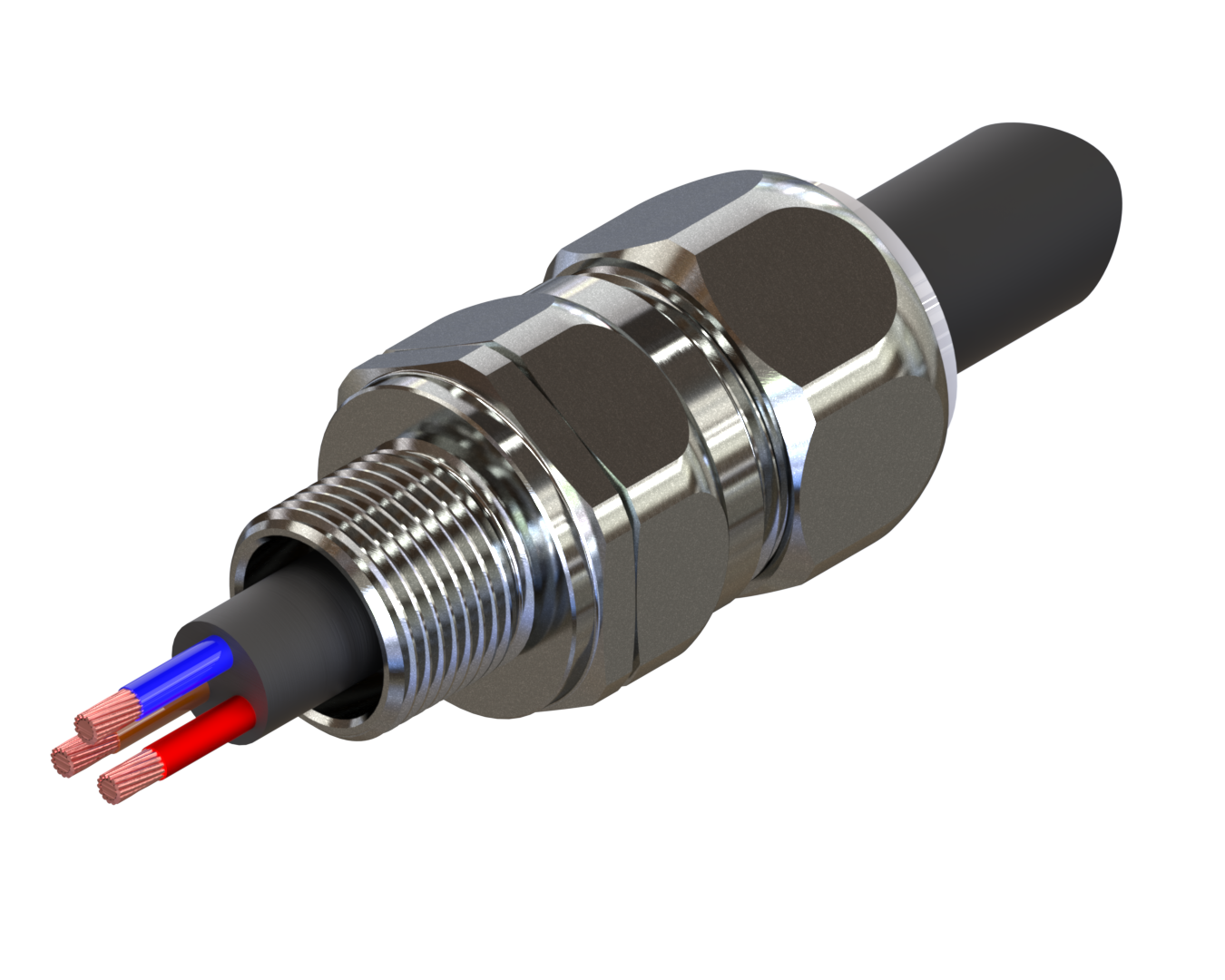

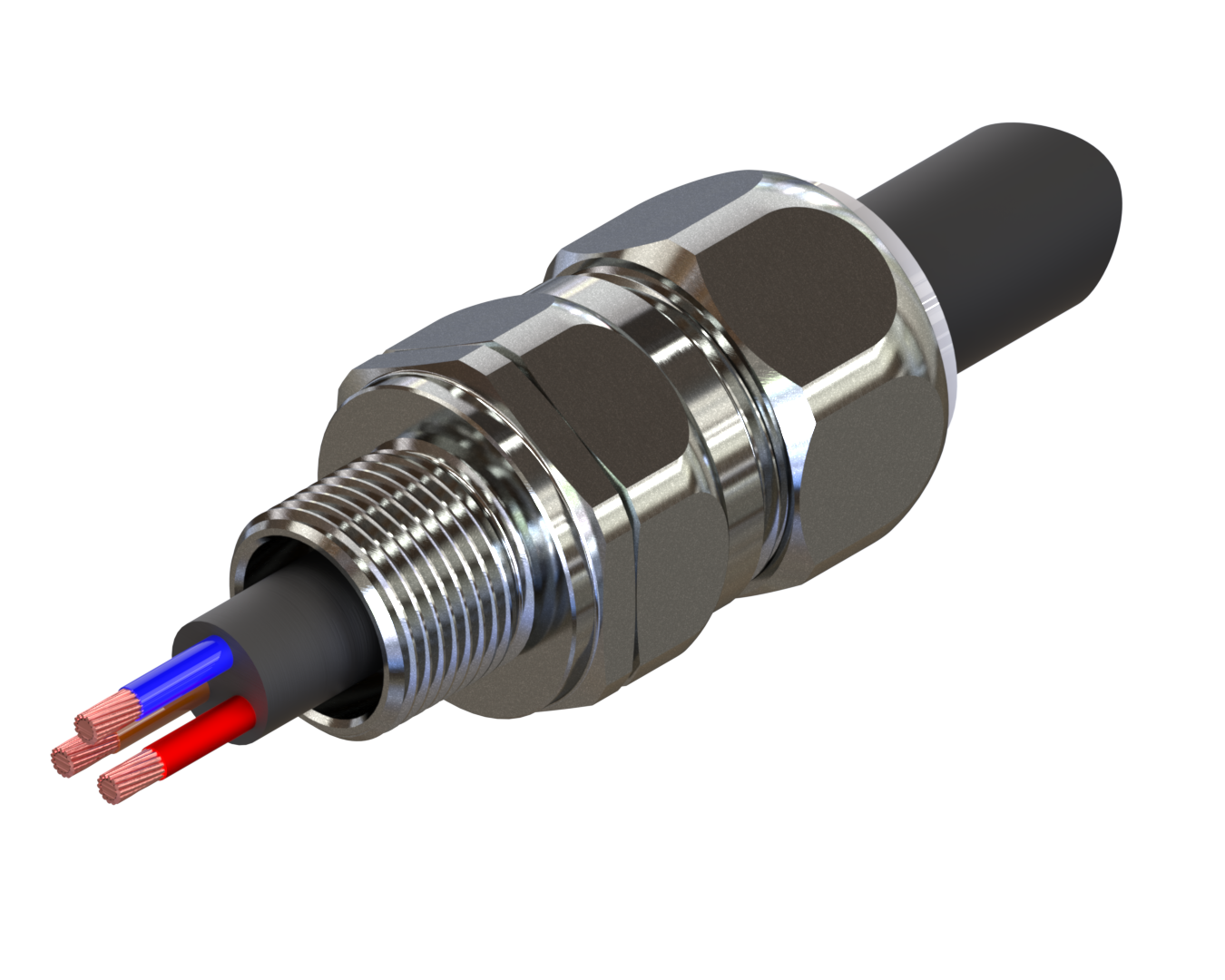

A2E | SSUA Cable Gland

The A2e range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

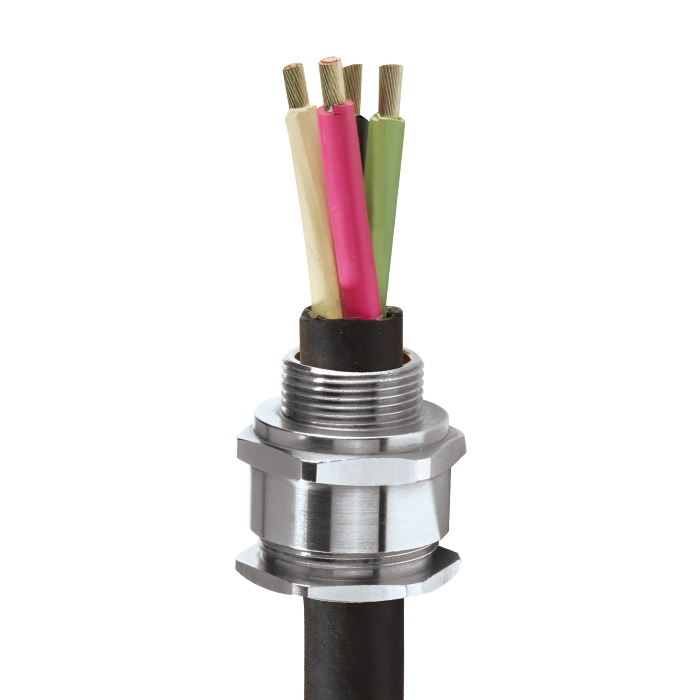

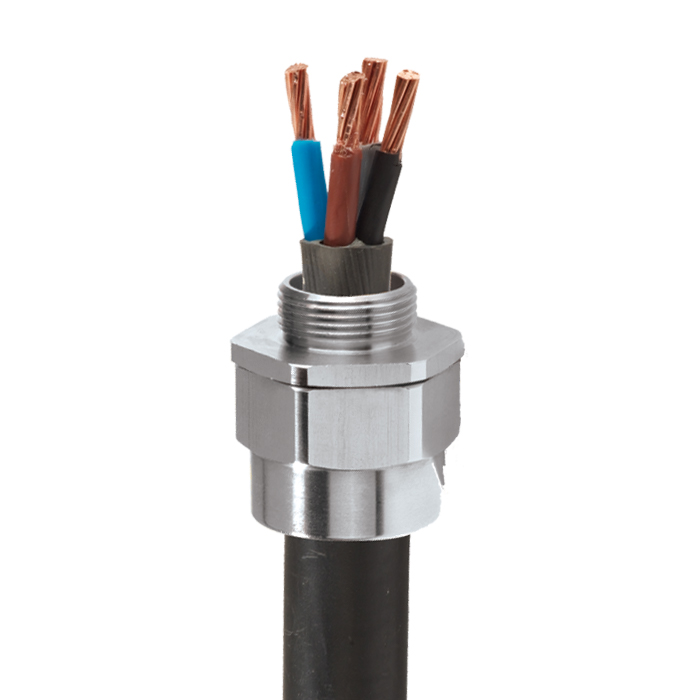

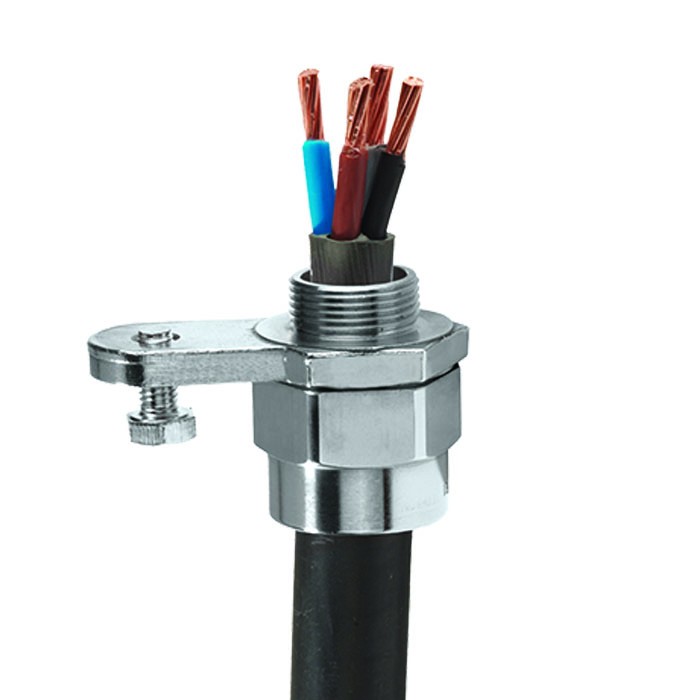

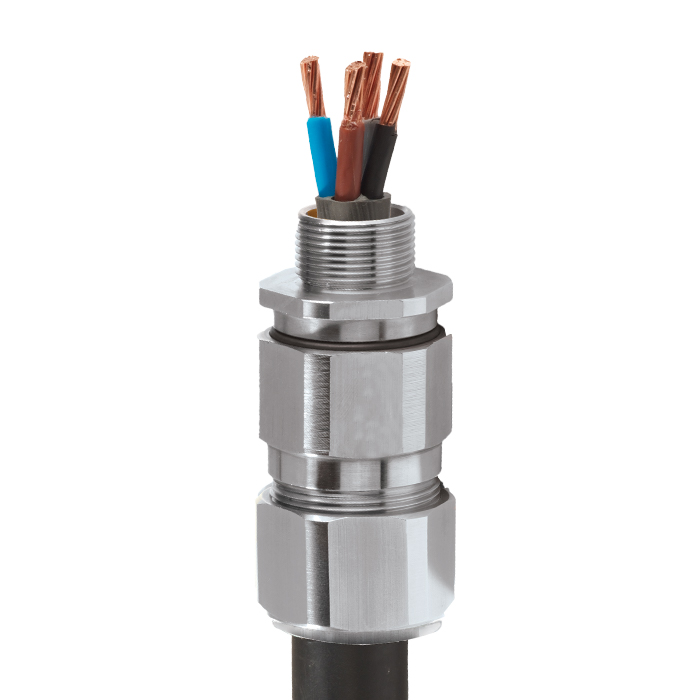

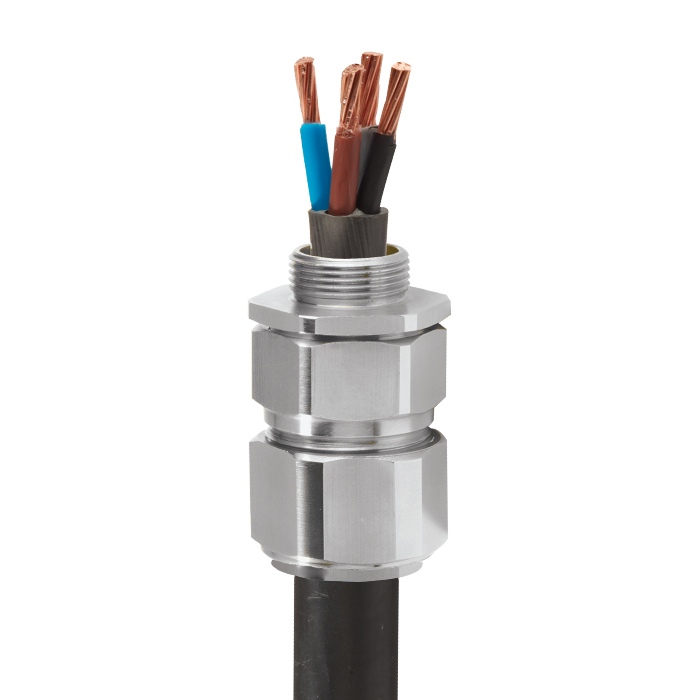

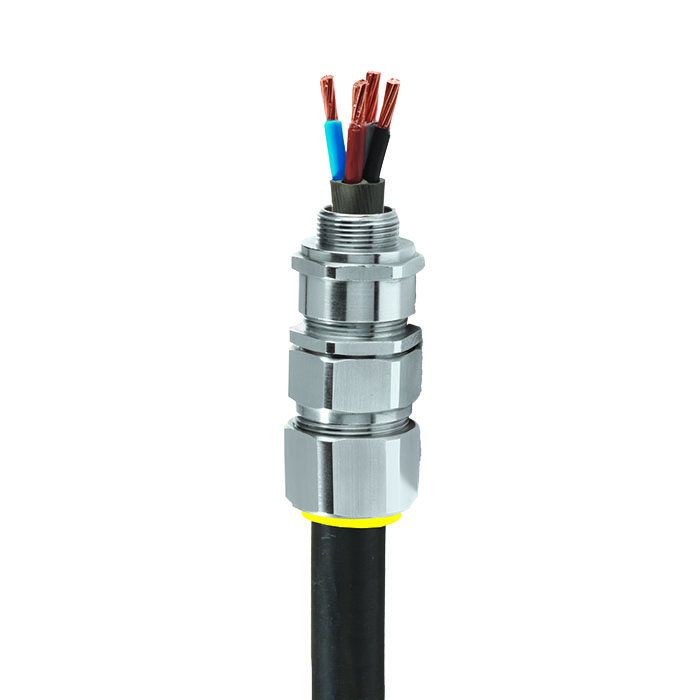

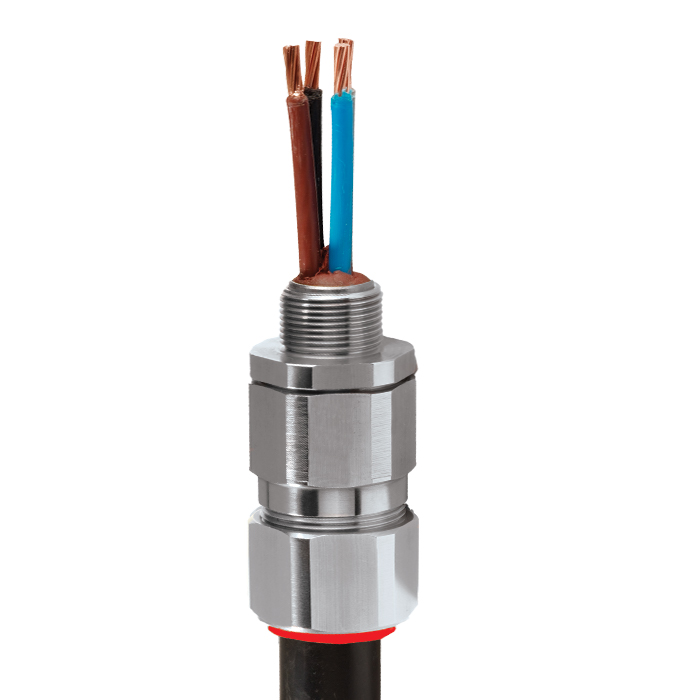

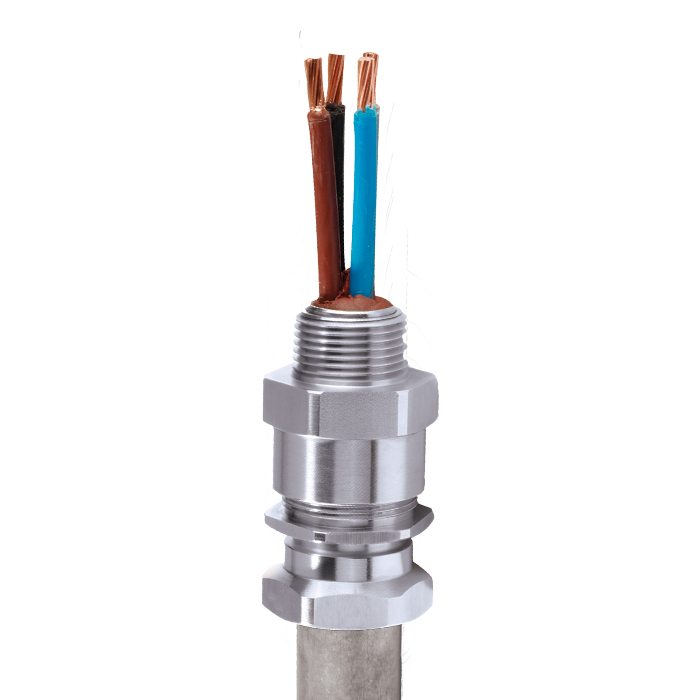

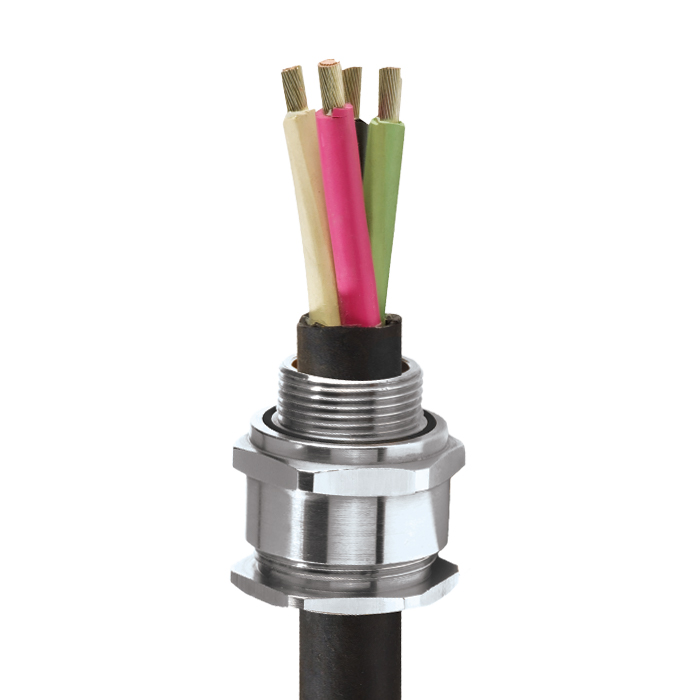

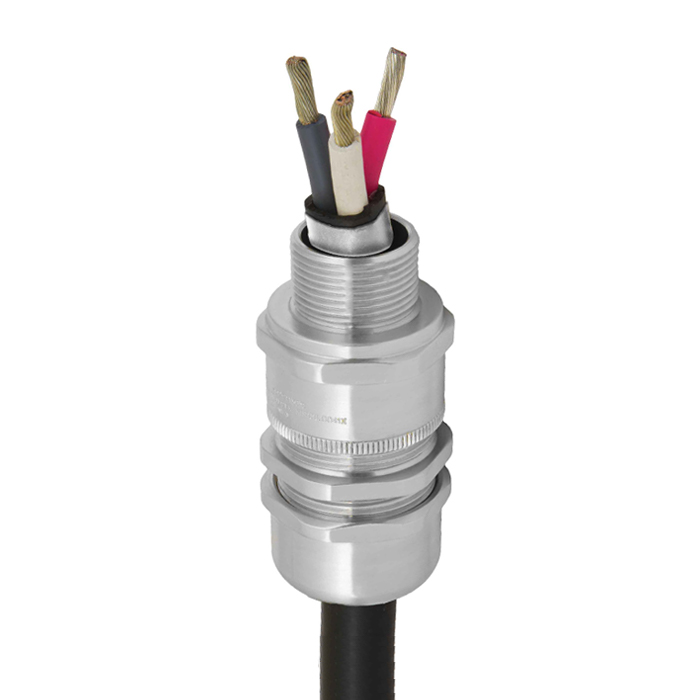

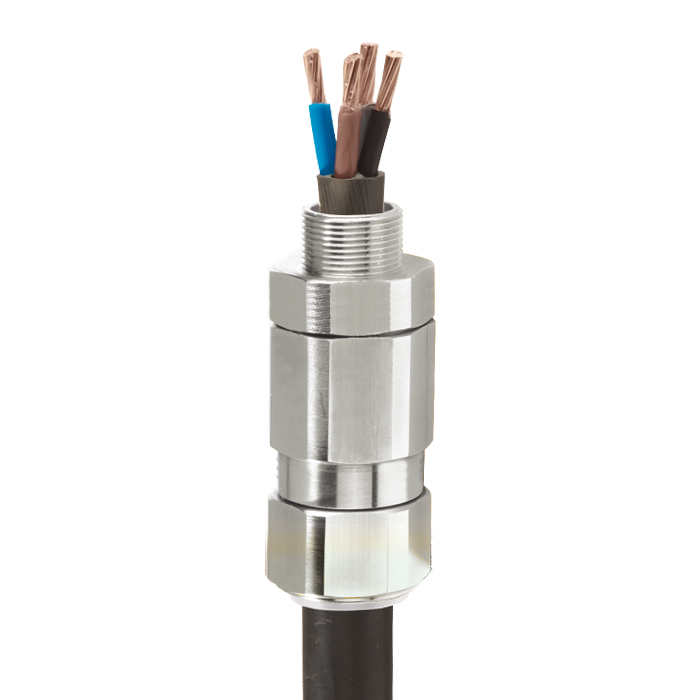

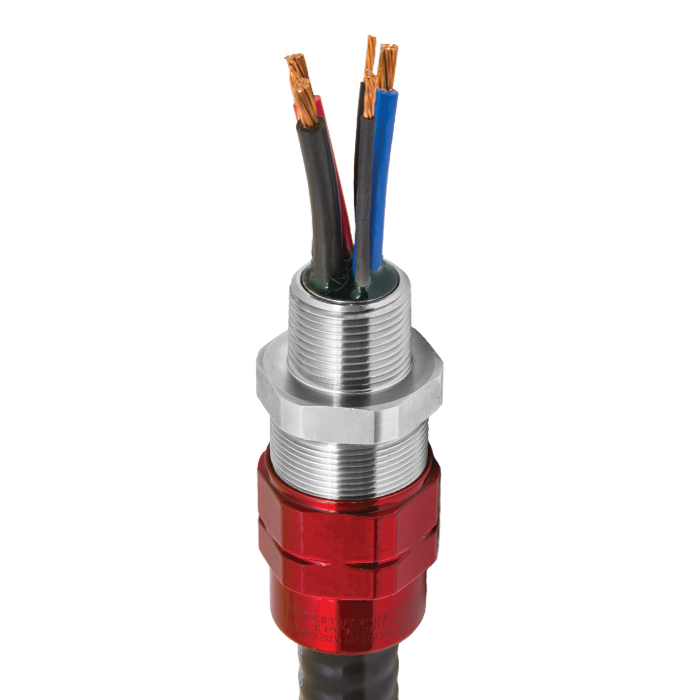

TSP | TruSeal Cable Gland

The TSP range of cable glands are for use in light / medium duty applications in Industrial Areas (Safe Areas). Designed to provide superior cable retention and strain relief.

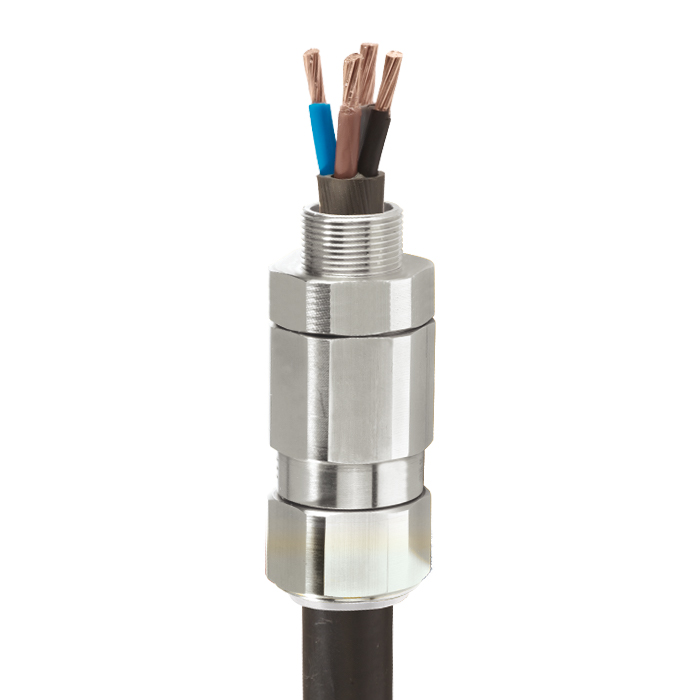

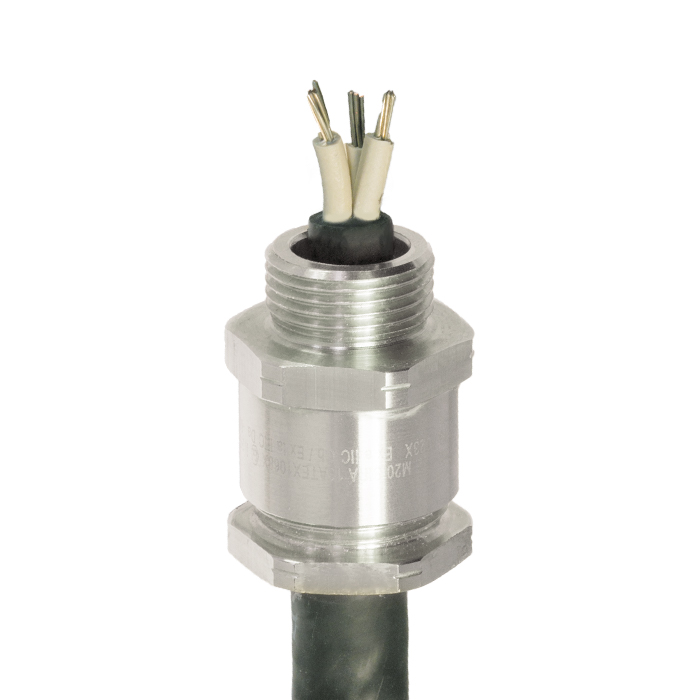

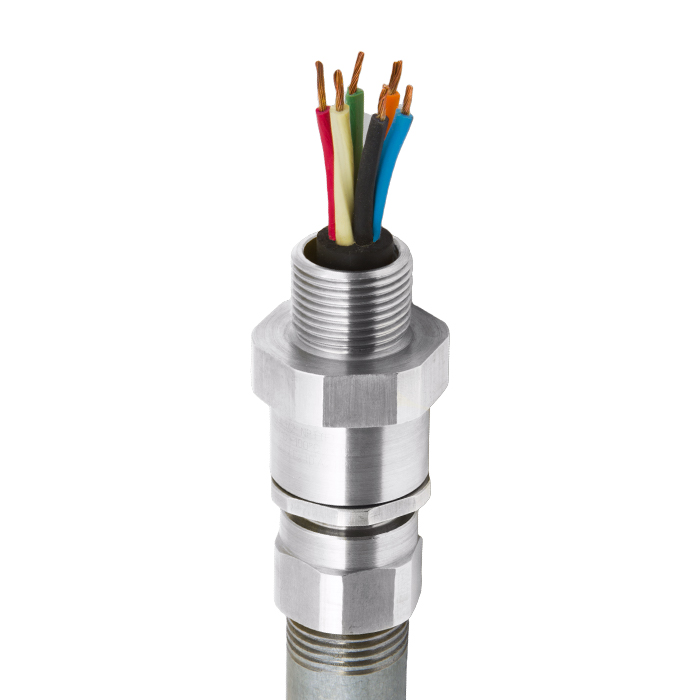

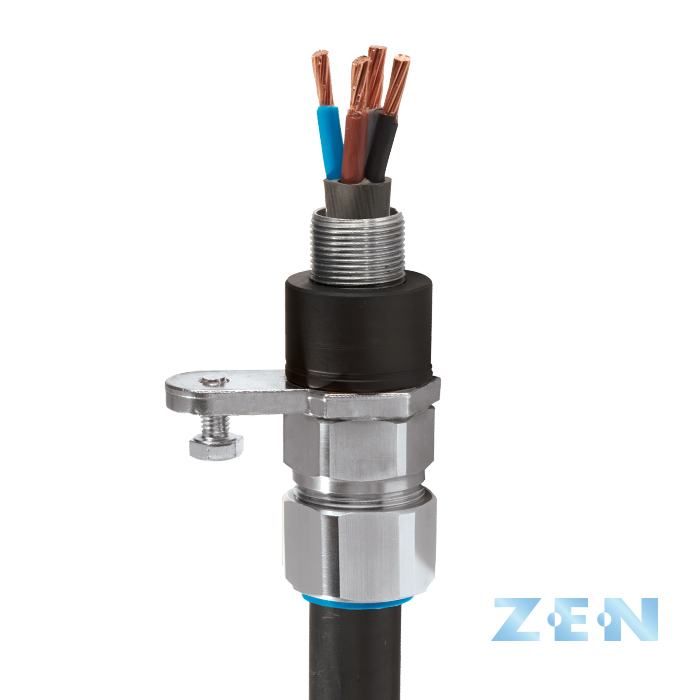

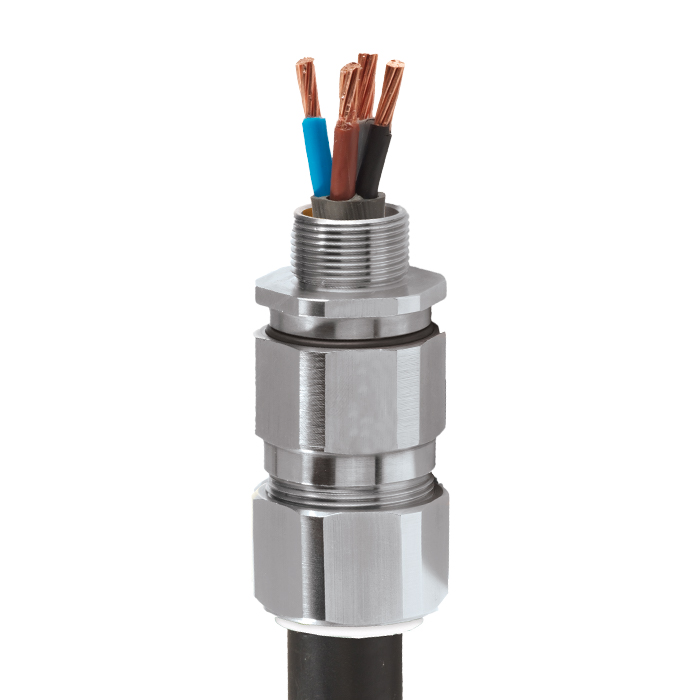

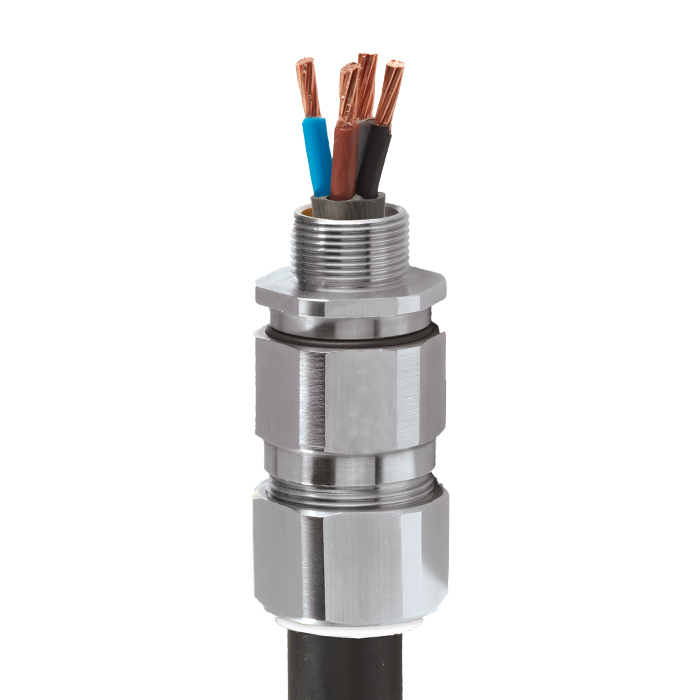

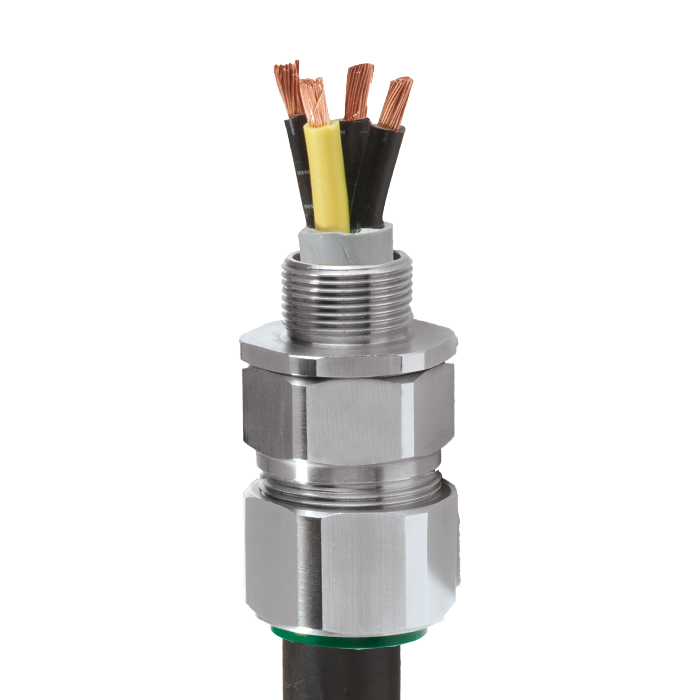

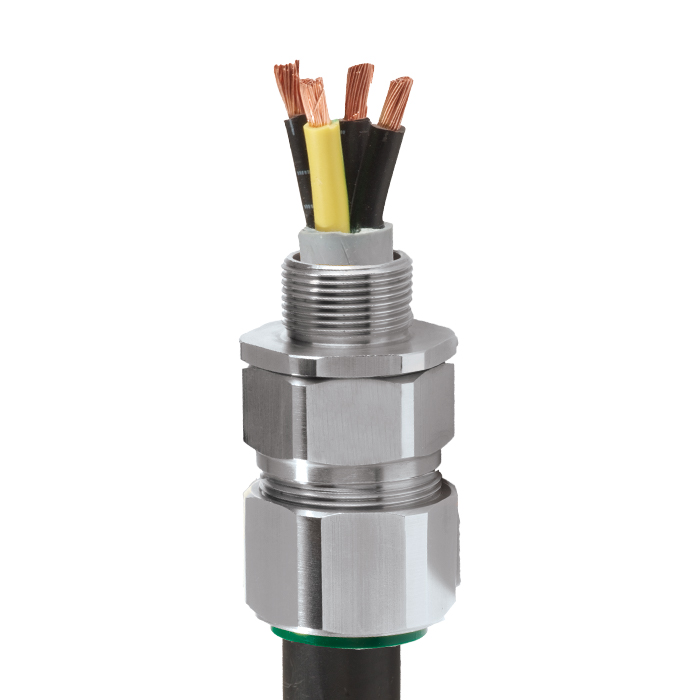

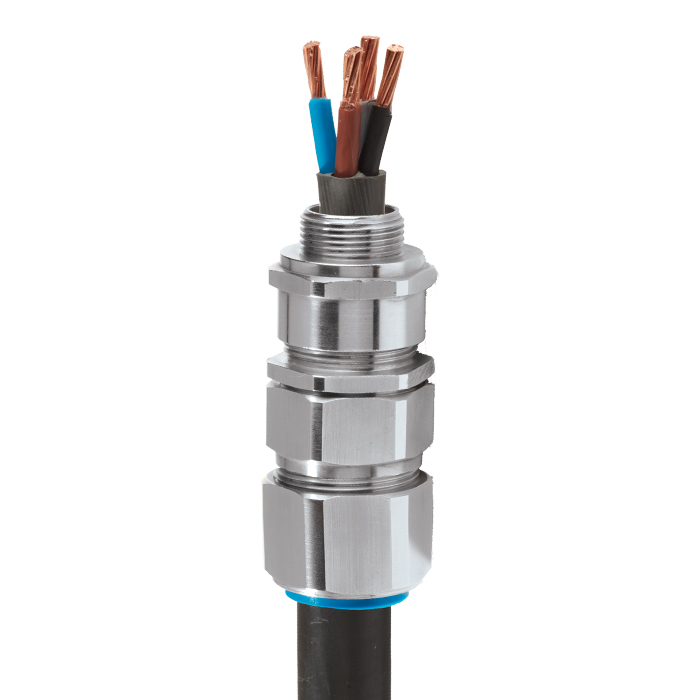

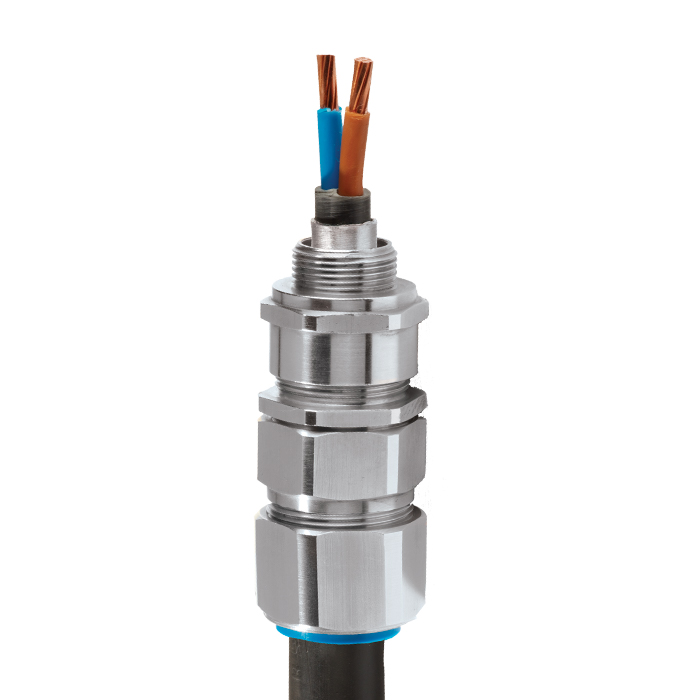

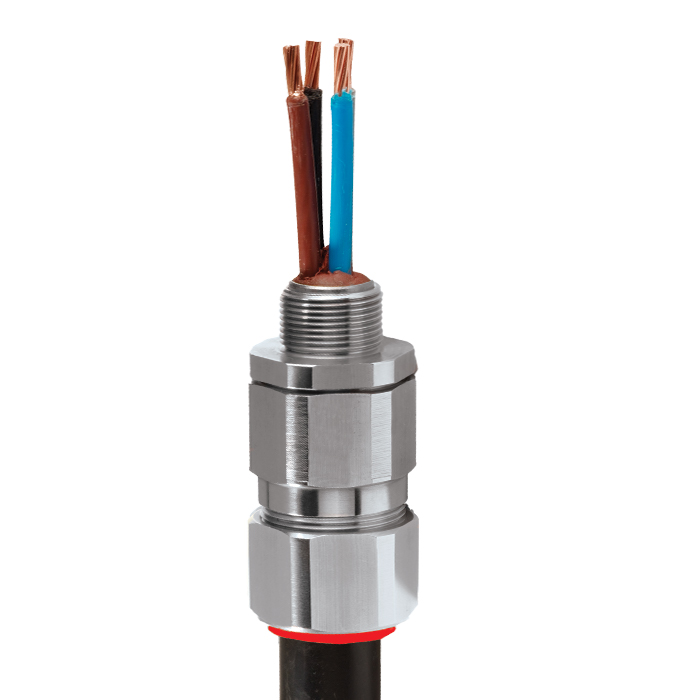

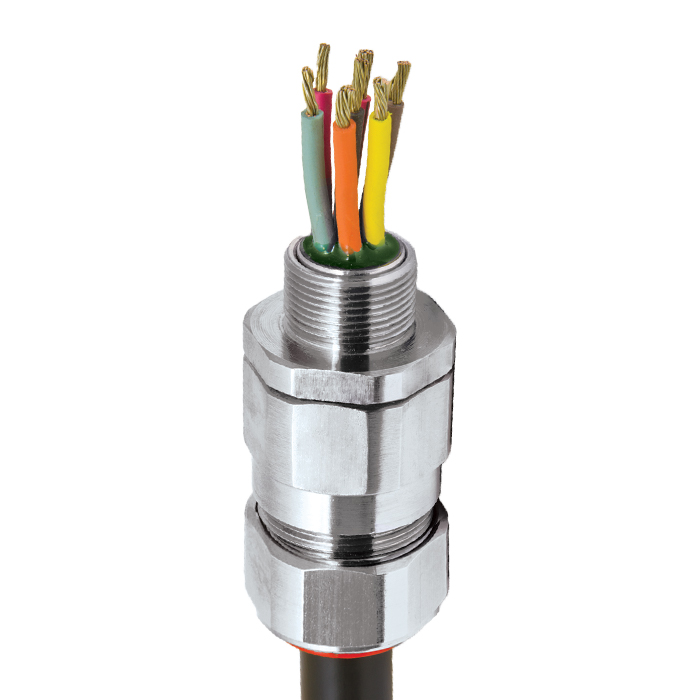

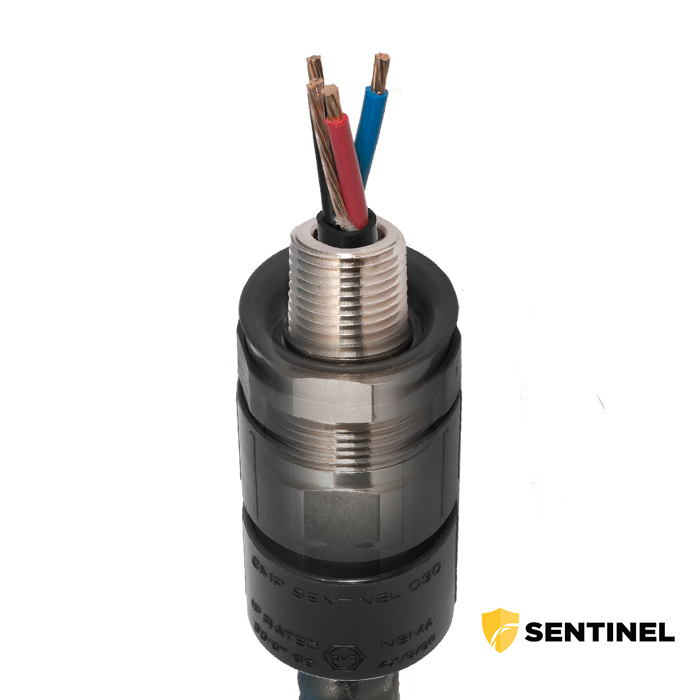

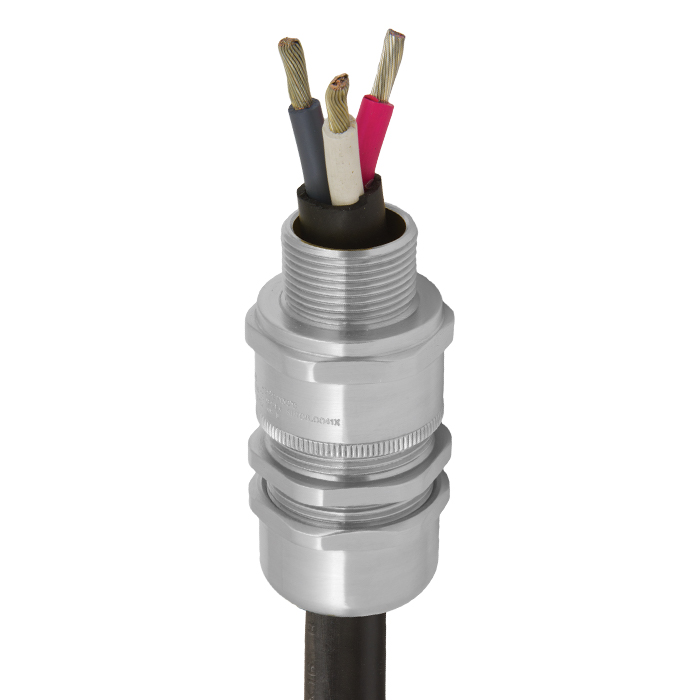

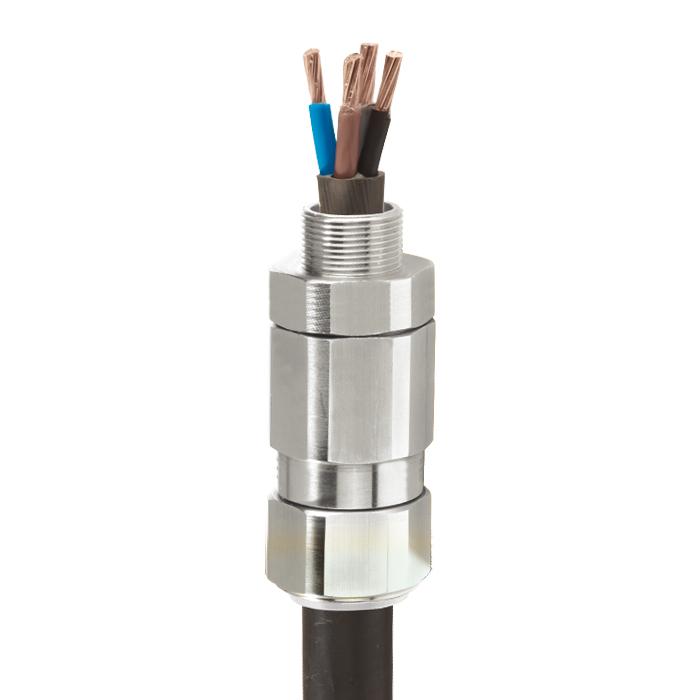

T3CDS | Triton Cable Gland

The Triton CDS range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a unique compensating displacement seal (CDS) to reduce the effects of coldflow.

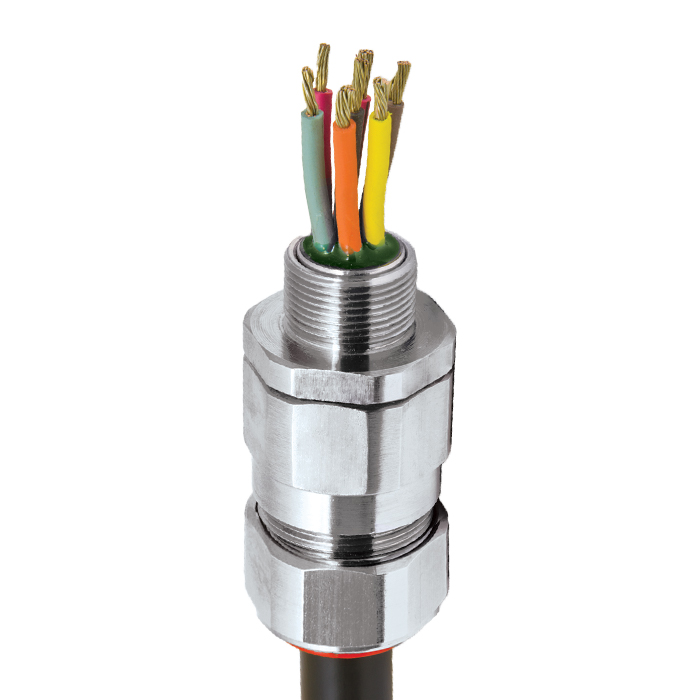

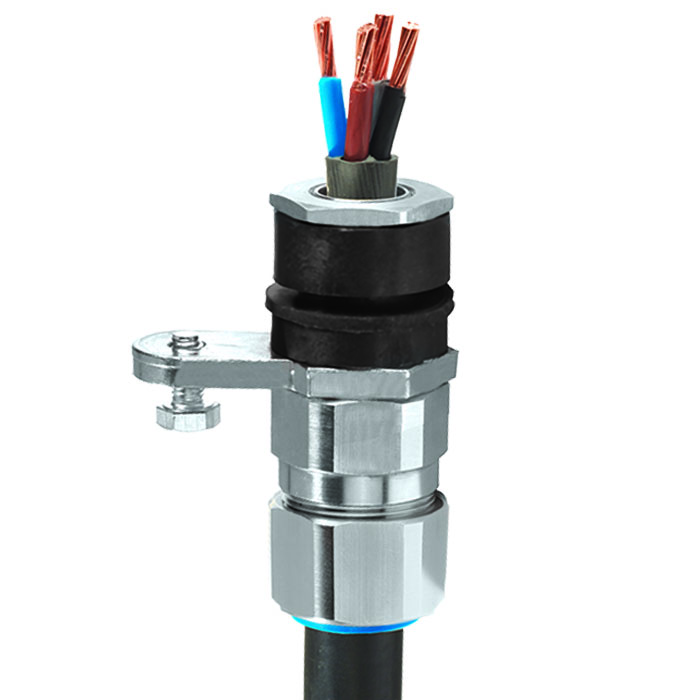

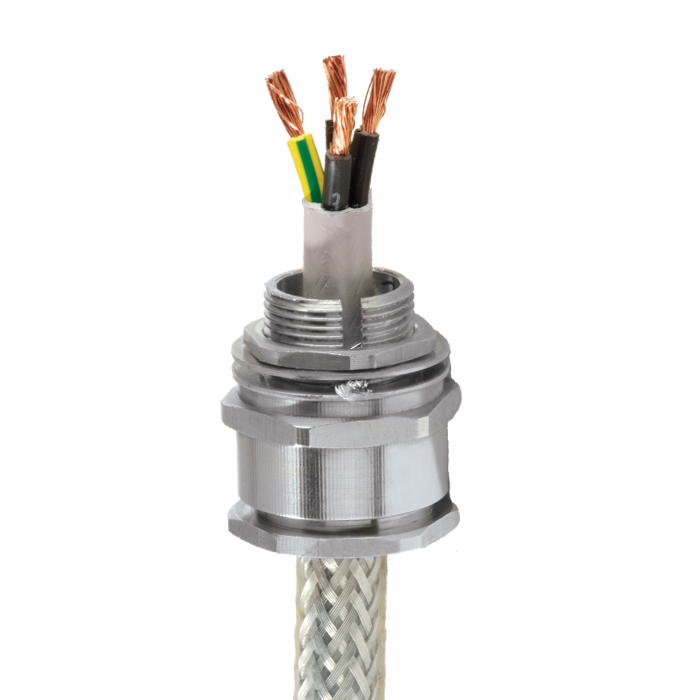

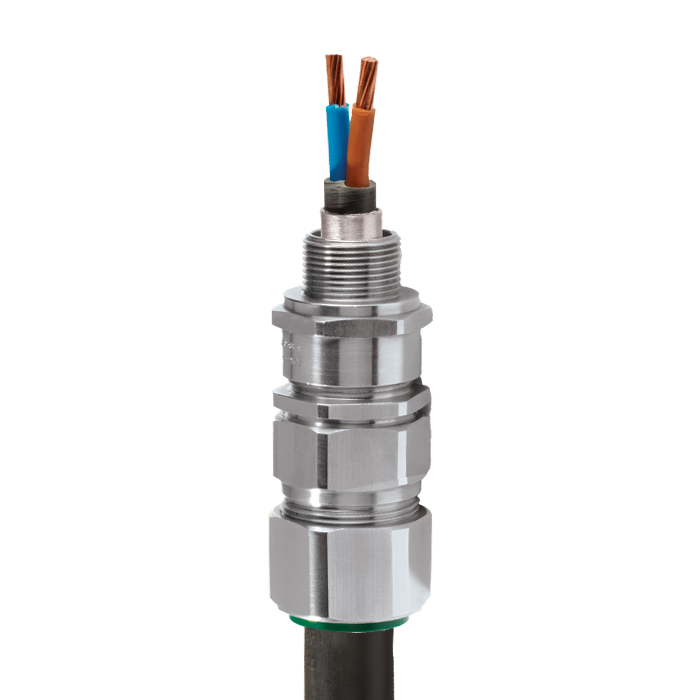

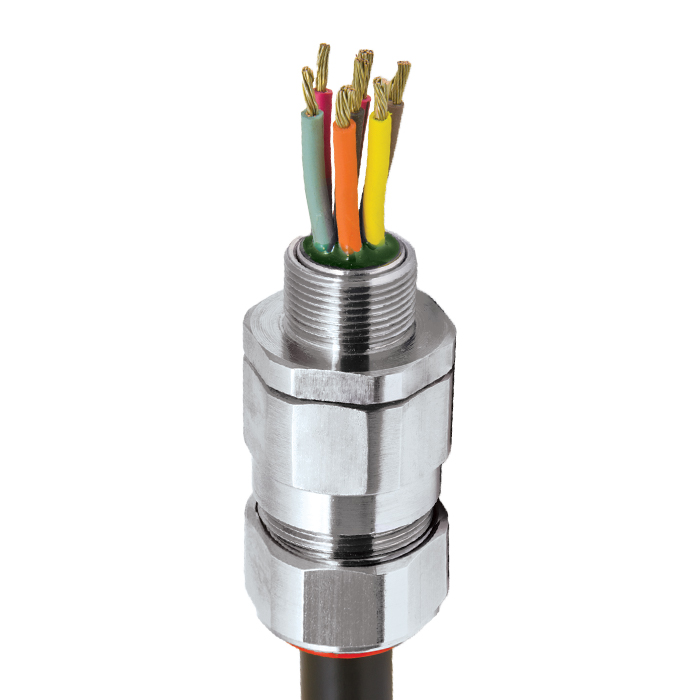

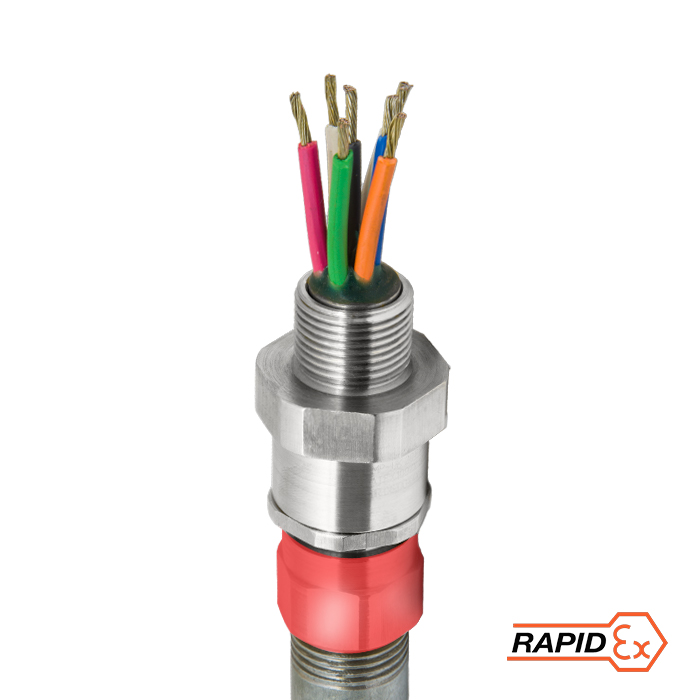

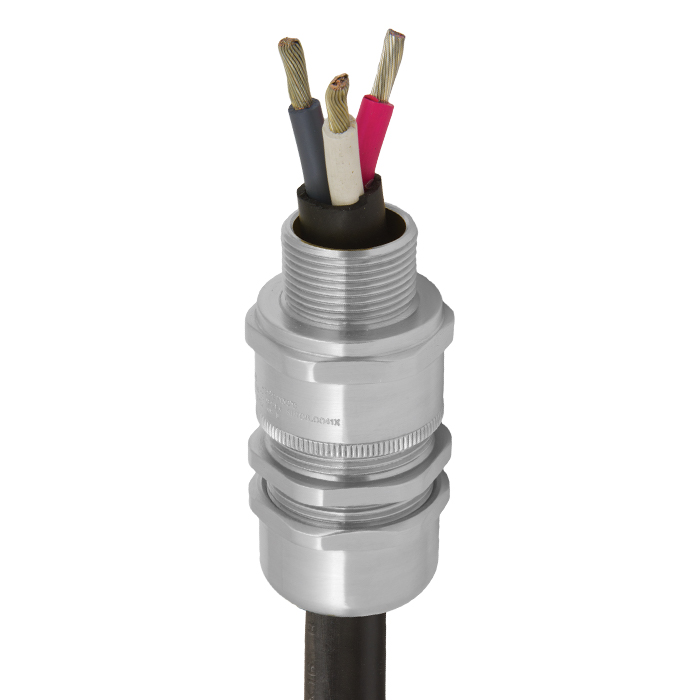

PX2KREX | PXREX Series Cable Gland

The PX2KREX range of RapidEx barrier cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed to prevent gas, vapour or fluid from migrating through a cable, or else prevent flame transmission from a Flameproof type ‘d’ enclosure, as determined by IEC 60079-14. The RapidEx liquid pour sealing system enhances reliability, reduces risk and significantly reduces curing time.

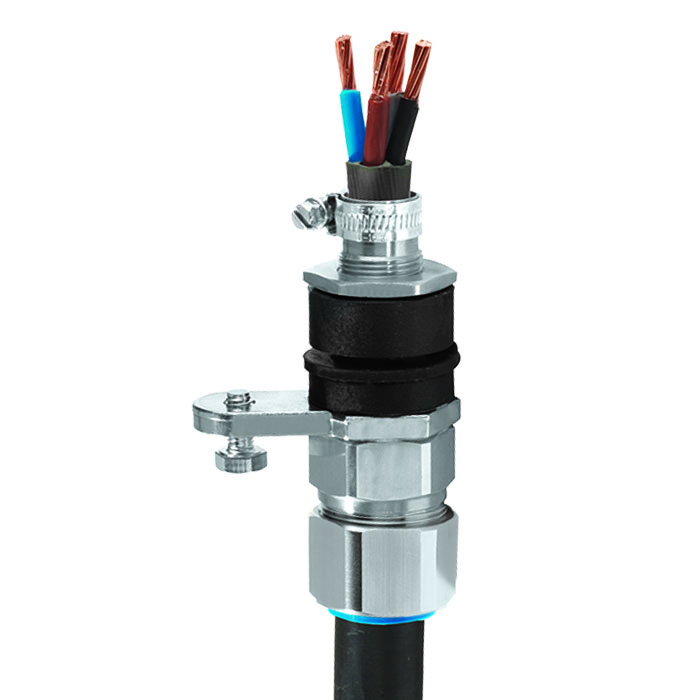

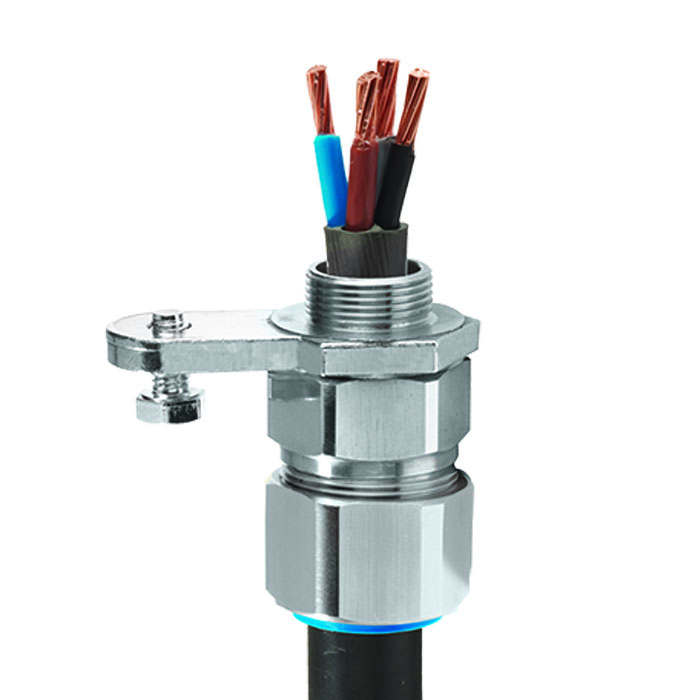

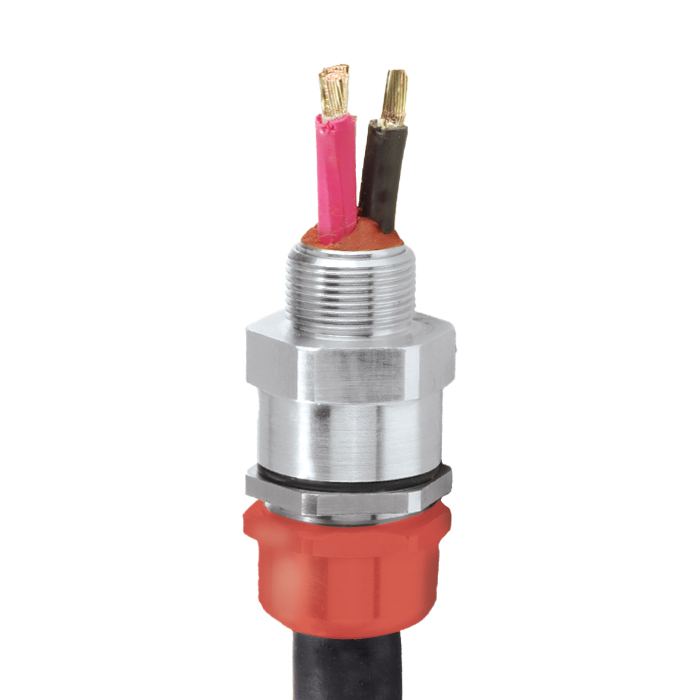

PX2KPBREX | PXREX Series Cable Gland

The PX2KPBREX range of RapidEx barrier cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed to prevent gas, vapour or fluid from migrating through a cable, or else prevent flame transmission from a Flameproof type ‘d’ enclosure, as determined by IEC 60079-14. The RapidEx liquid pour sealing system enhances reliability, reduces risk and significantly reduces curing time.

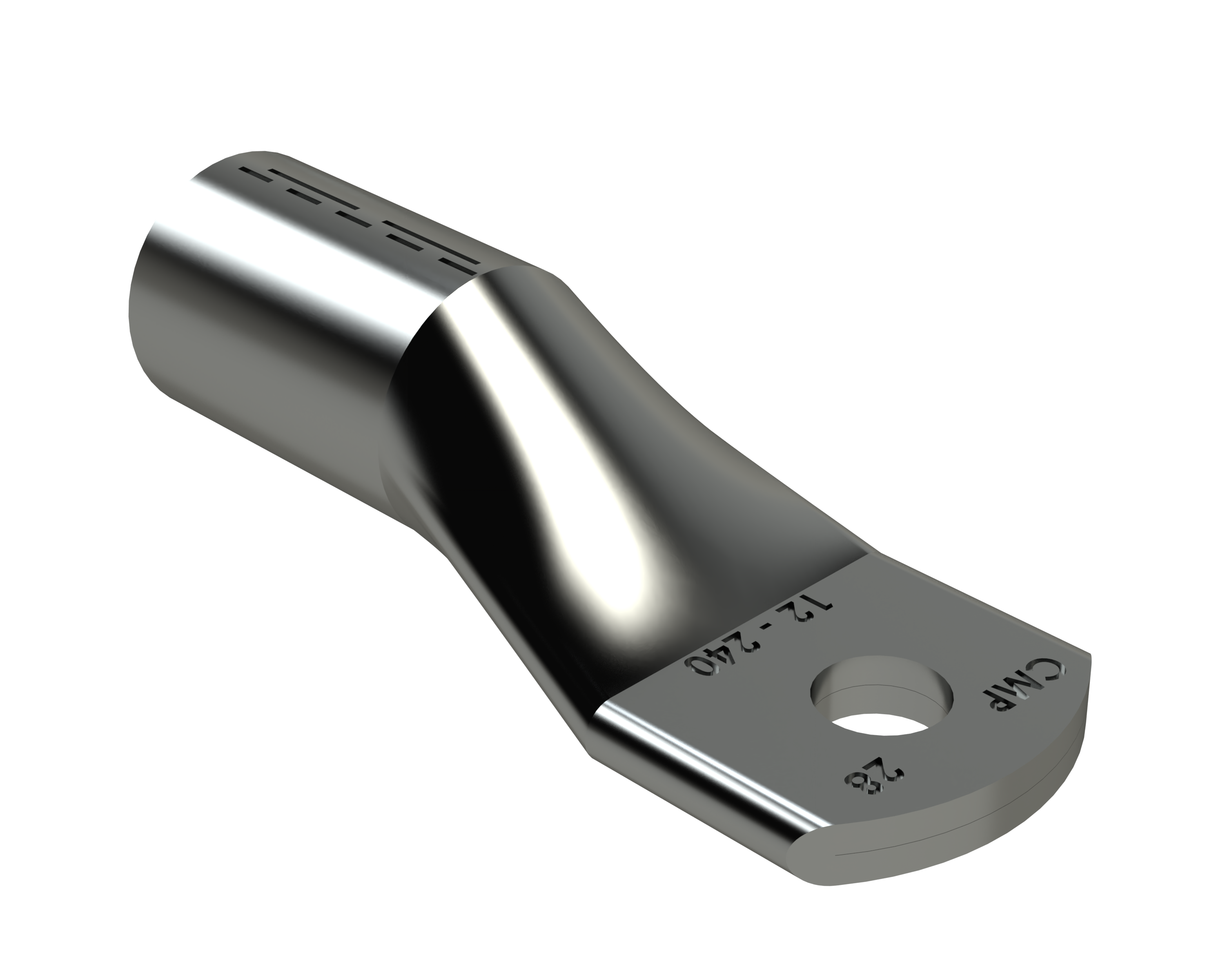

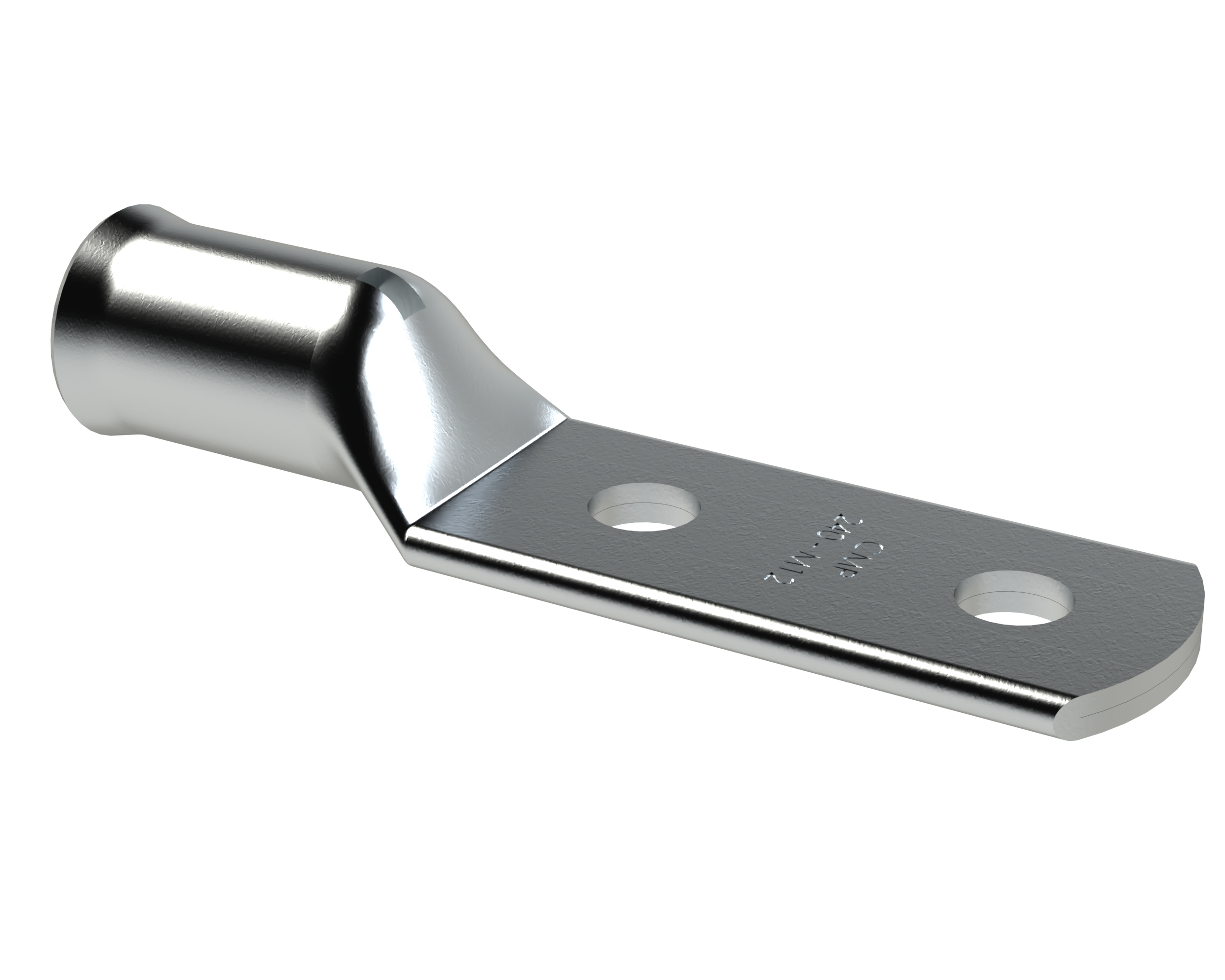

CDNP1 | DIN Cable Lug Cable Lug

These products have been designed to match the dimensions of DIN 46235 for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

CHDP2 | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CHDP212X. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

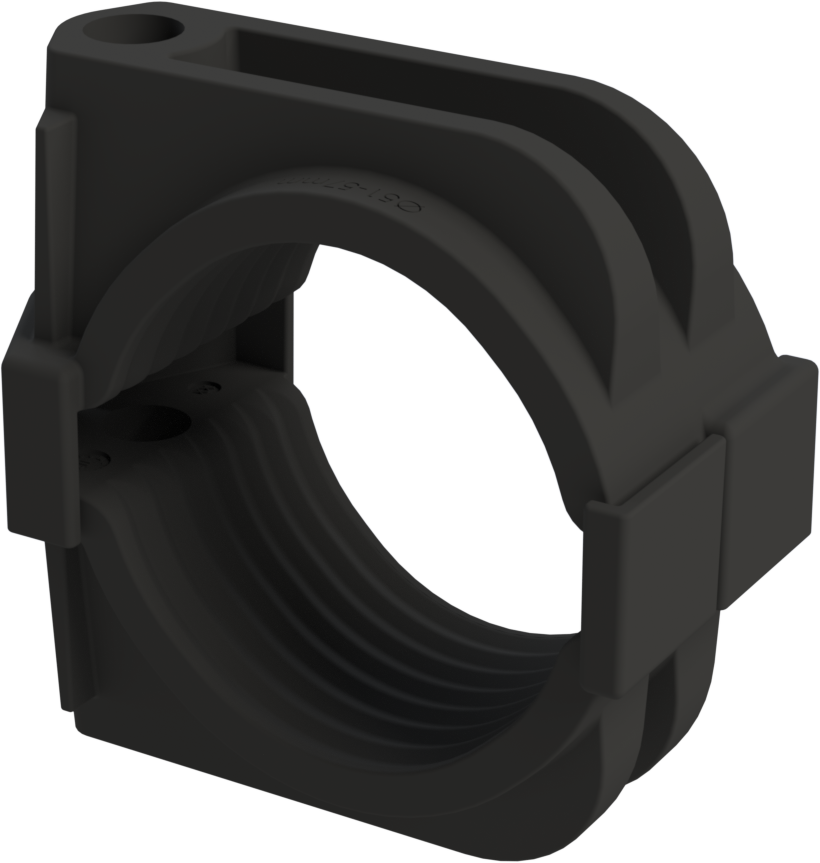

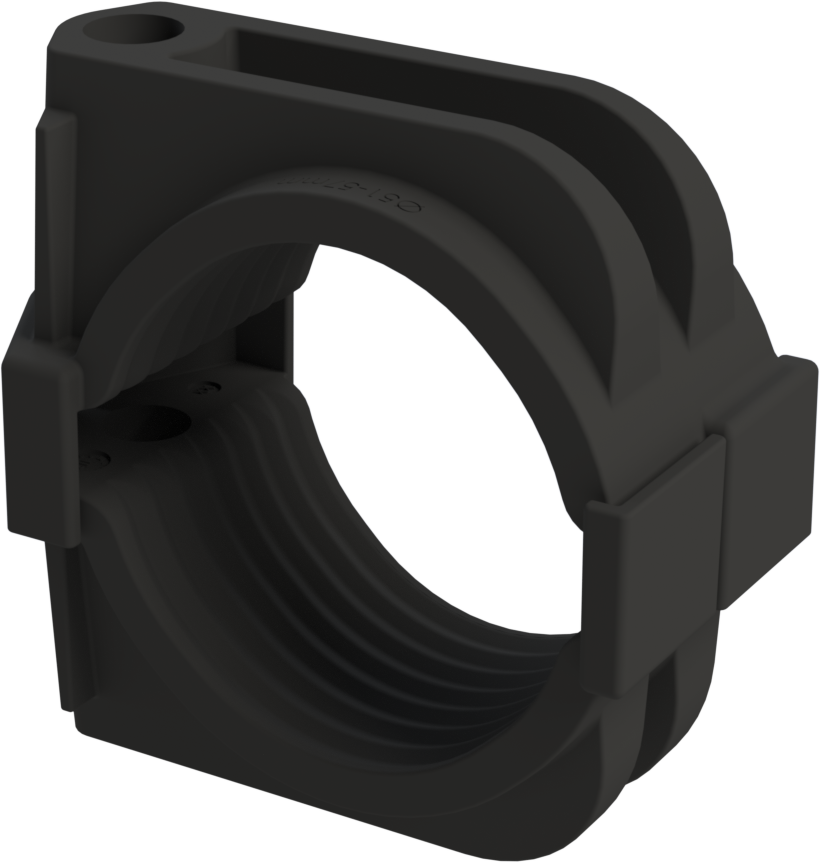

1BC | Sabre Cable Cleat

The CMP Sabre is a single non-metallic (polymeric) cable cleat, designed and tested in accordance with IEC 61914. Manufactured from Injection Moulded Nylon. Due to its unique twin arc internal profile, this product exhibits excellent cable retention, limiting both axial and lateral cable movement. The single fixing design provides quick and easy installation in any orientation the cable route may take. There is one M10 clearance hole for versatile fixing of the cable cleat.

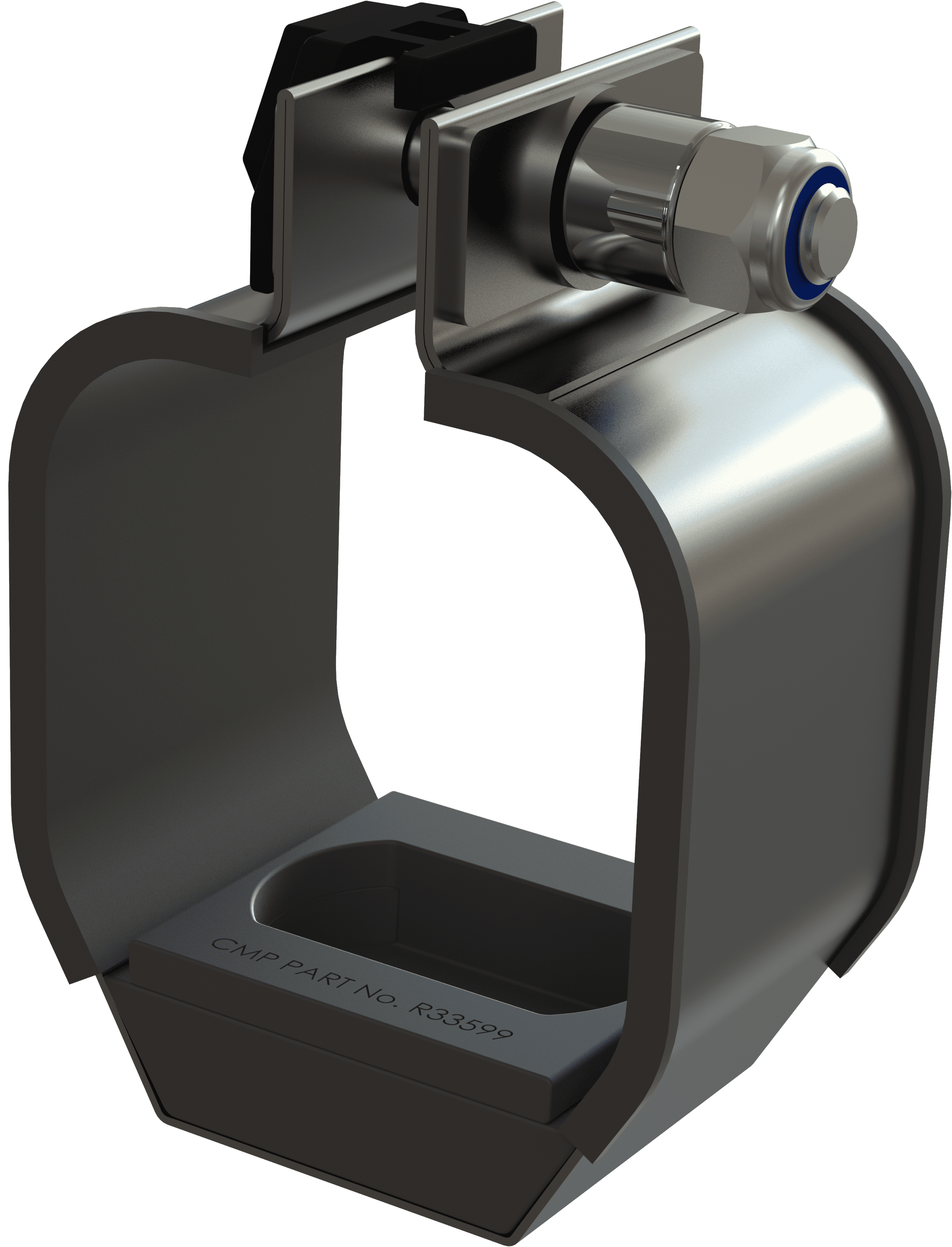

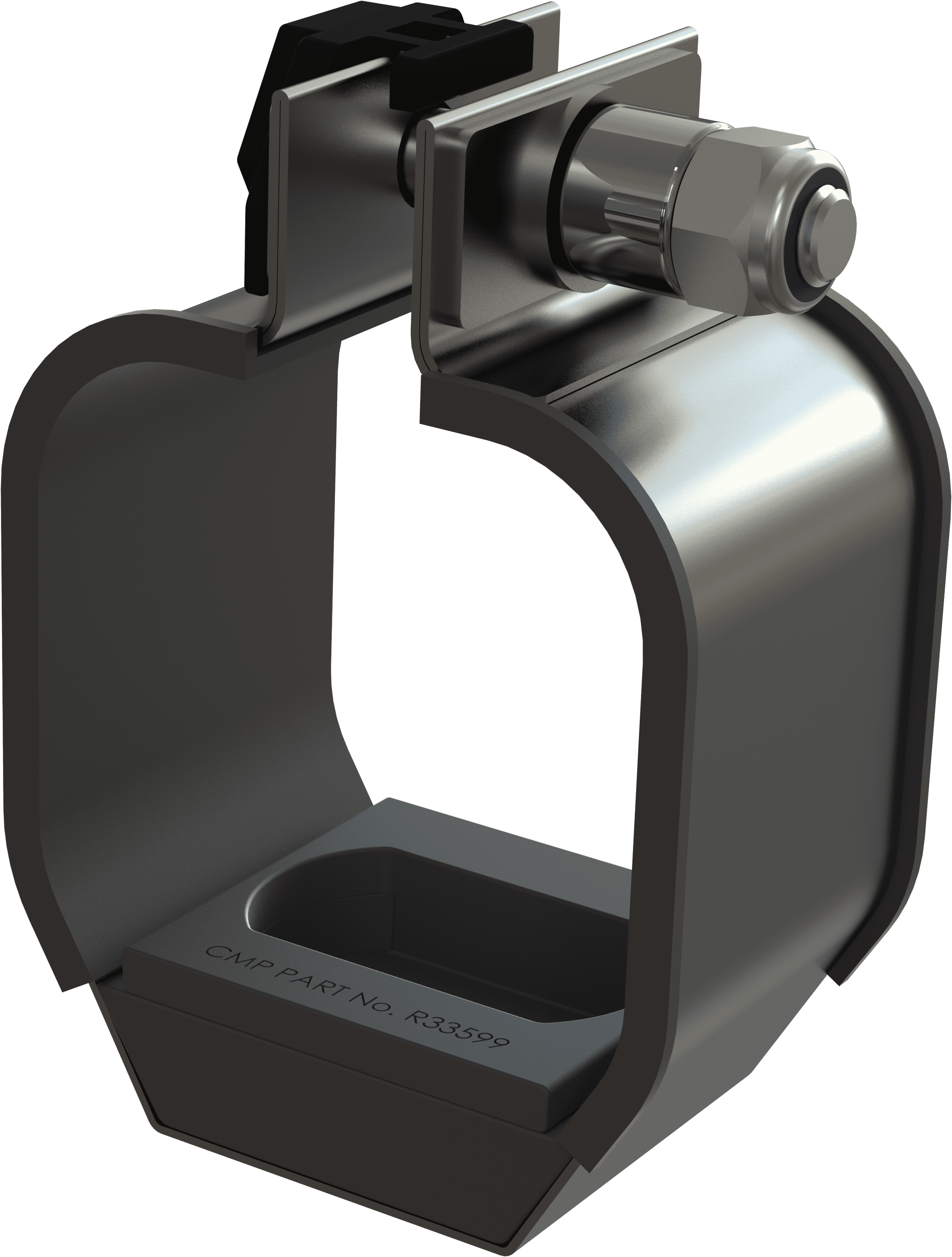

LDAL-C-HT | Legion Cable Cleat

The CMP Legion High Temperature is a trefoil composite cable cleat, designed and tested in accordance with IEC 61914. Manufactured from 5000 Series Aluminium with a high temperature resistant Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric base to protect the cable sheath and enable the cable cleat to withstand temperatures of -60°C to +130°C during normal operation. The metal surround has been edge rounded and deburred to reduce risk of cable sheath damage. The top opening is designed to fit more cleats installed side-by-side and includes a fully opening hinge for ease of installation. The three M10 fixing clearance holes in the base allows versatility of fixing the cleat to the mounting structure.

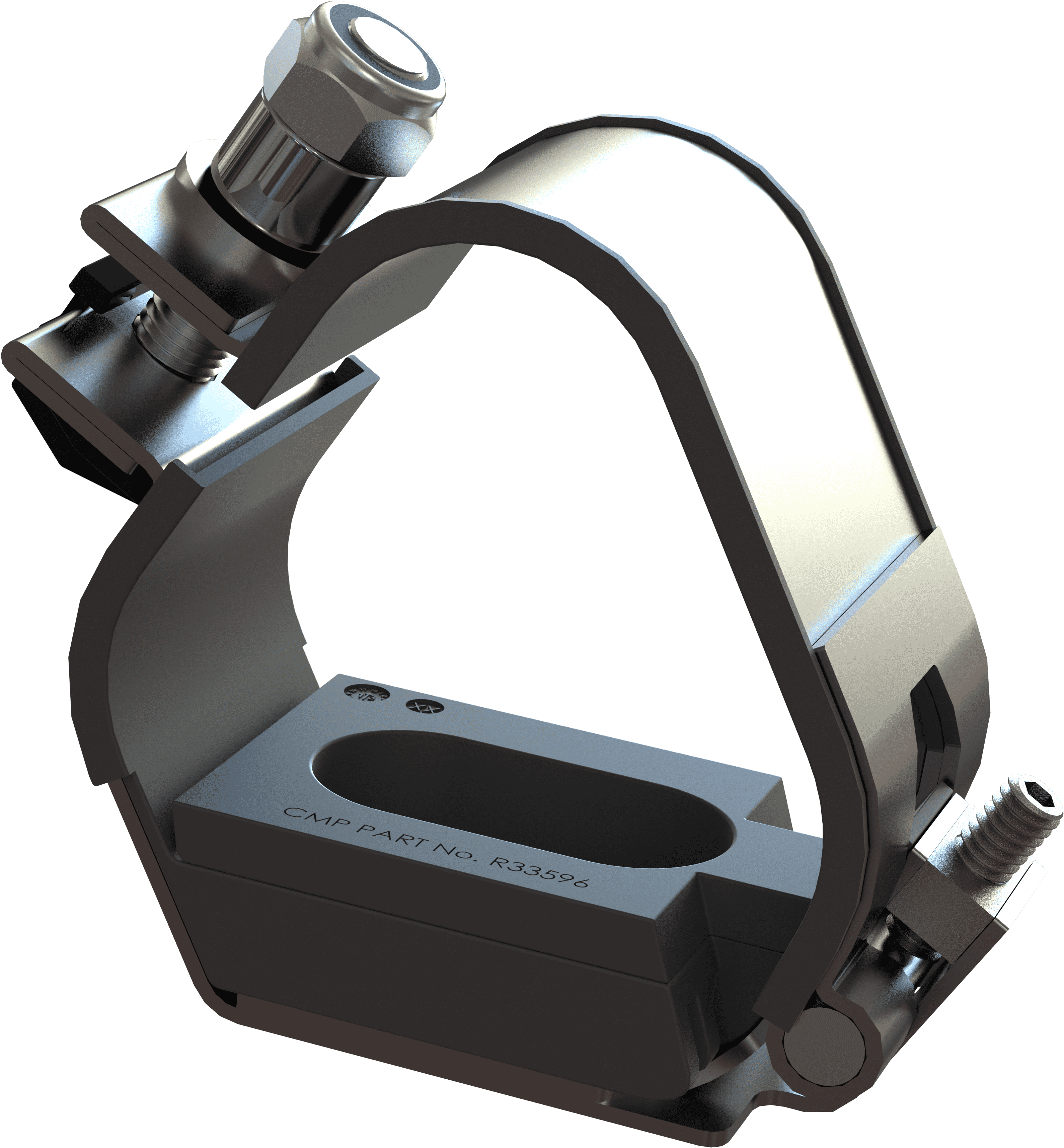

QSDSS | Saturn Cable Cleat

The CMP Saturn is a quad composite cable cleat, designed and tested in accordance with IEC 61914. Manufactured from 316L Stainless Steel with Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric liners to protect the cable sheath. The cleat is designed to accept four cables of the same size, for example three phase power cables plus a neutral cable. The top opening is designed to fit more cleats installed side-by-side. Flexible materials allow a wide opening for easy cable installation and the cleat is easily formed around the cables for closure. The three M10 fixing clearance holes in the base allows versatility of fixing the cleat to the mounting structure.

SDSS | Patriot Cable Cleat

The CMP Patriot is a trefoil composite cable cleat, designed and tested in accordance with IEC 61914. Manufactured from 316L Stainless Steel with Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric liners to protect the cable sheath. The single closing fixture with captive bolt ensures a quick installation. The fully opening hinge allows the cable cleat to be opened wide for easy cable installation, and the single closing fixture with captive bolt ensures a quick installation. The three M10 fixing clearance holes in the base allows versatility of fixing the cleat to the mounting structure.

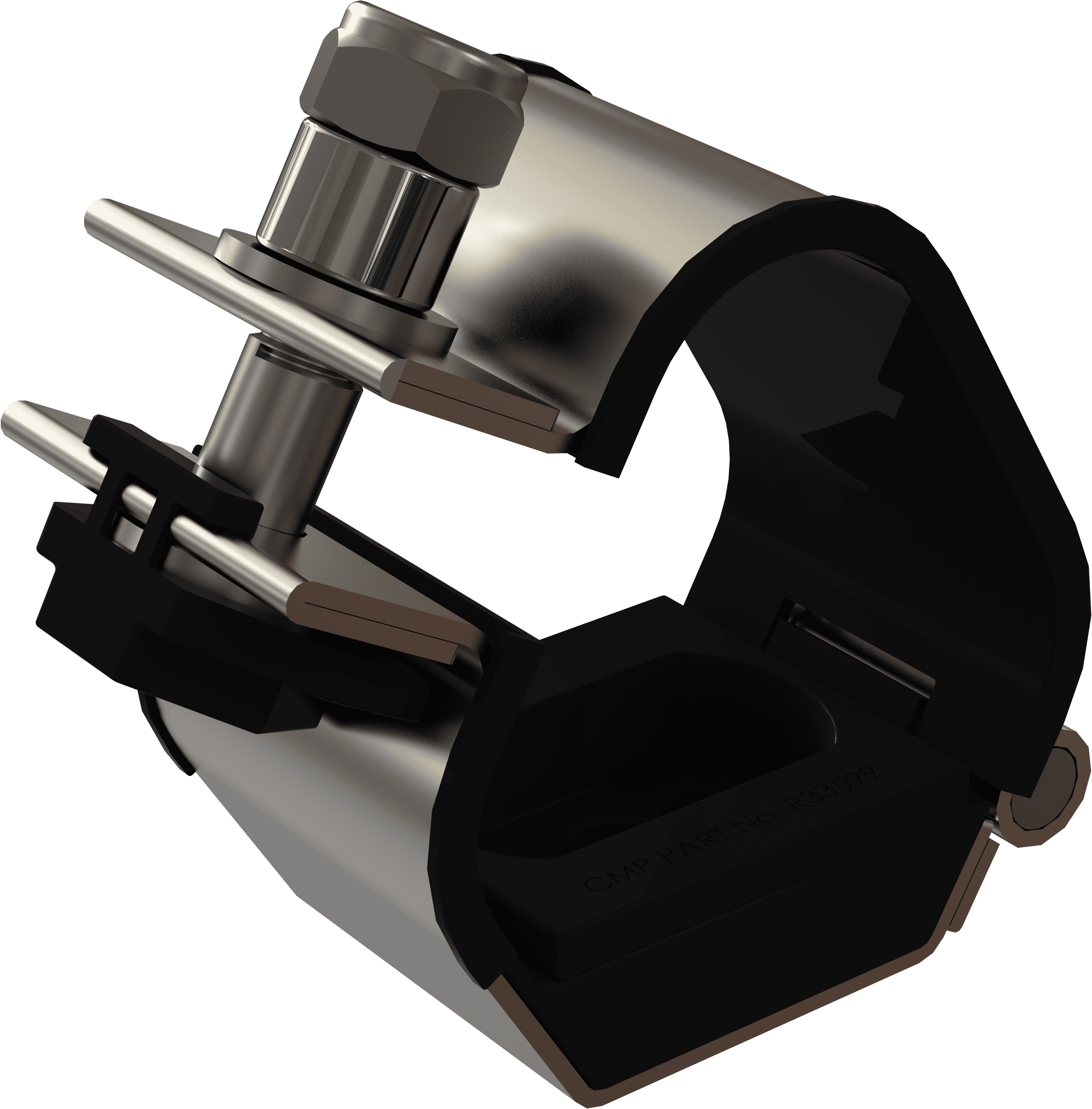

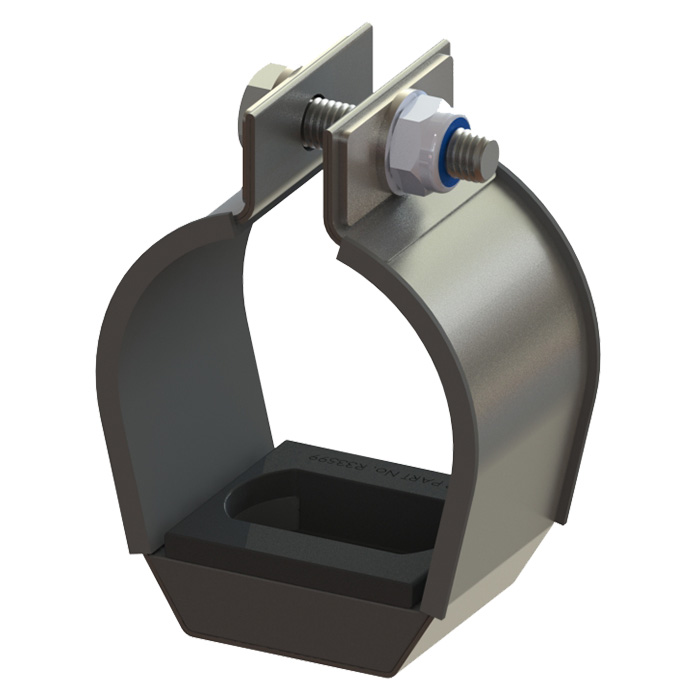

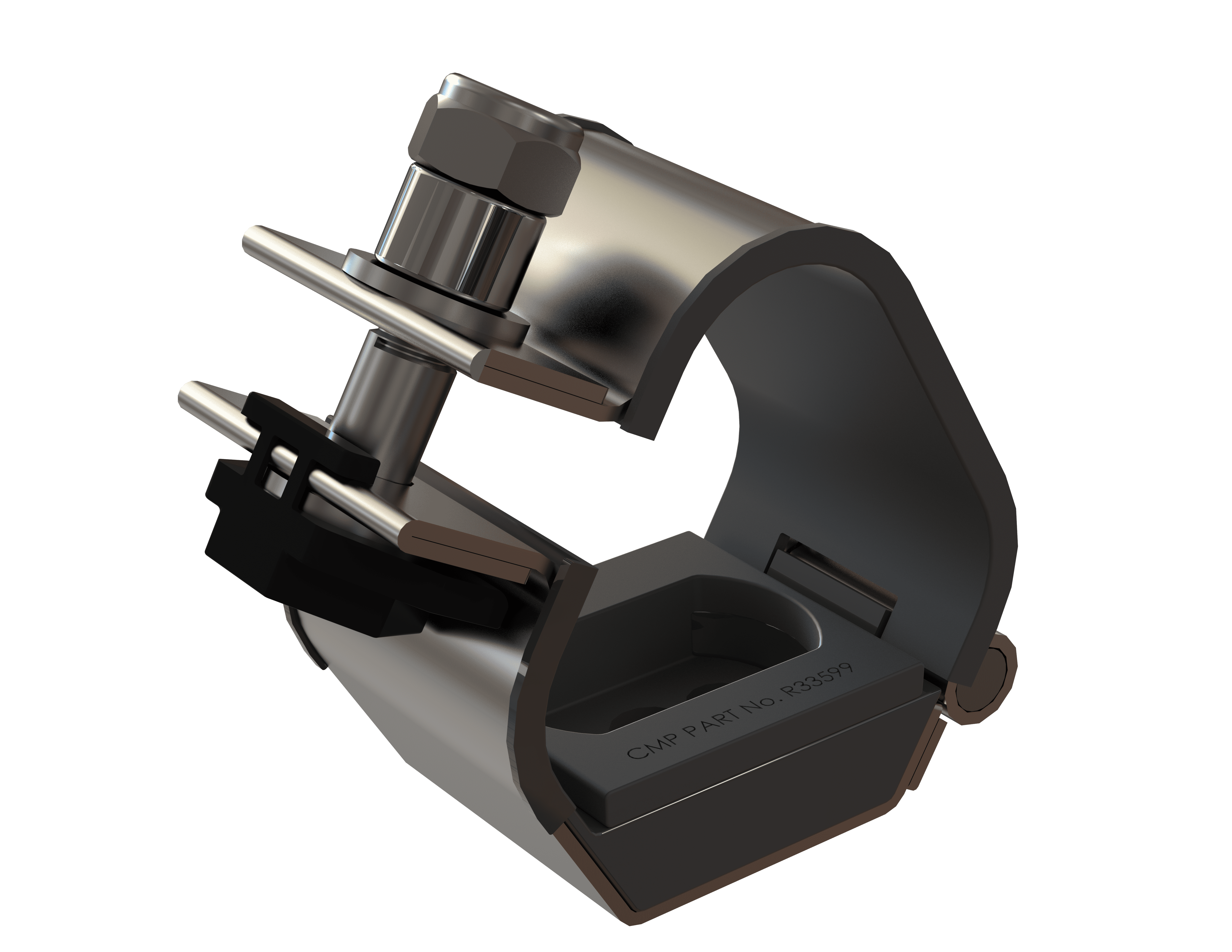

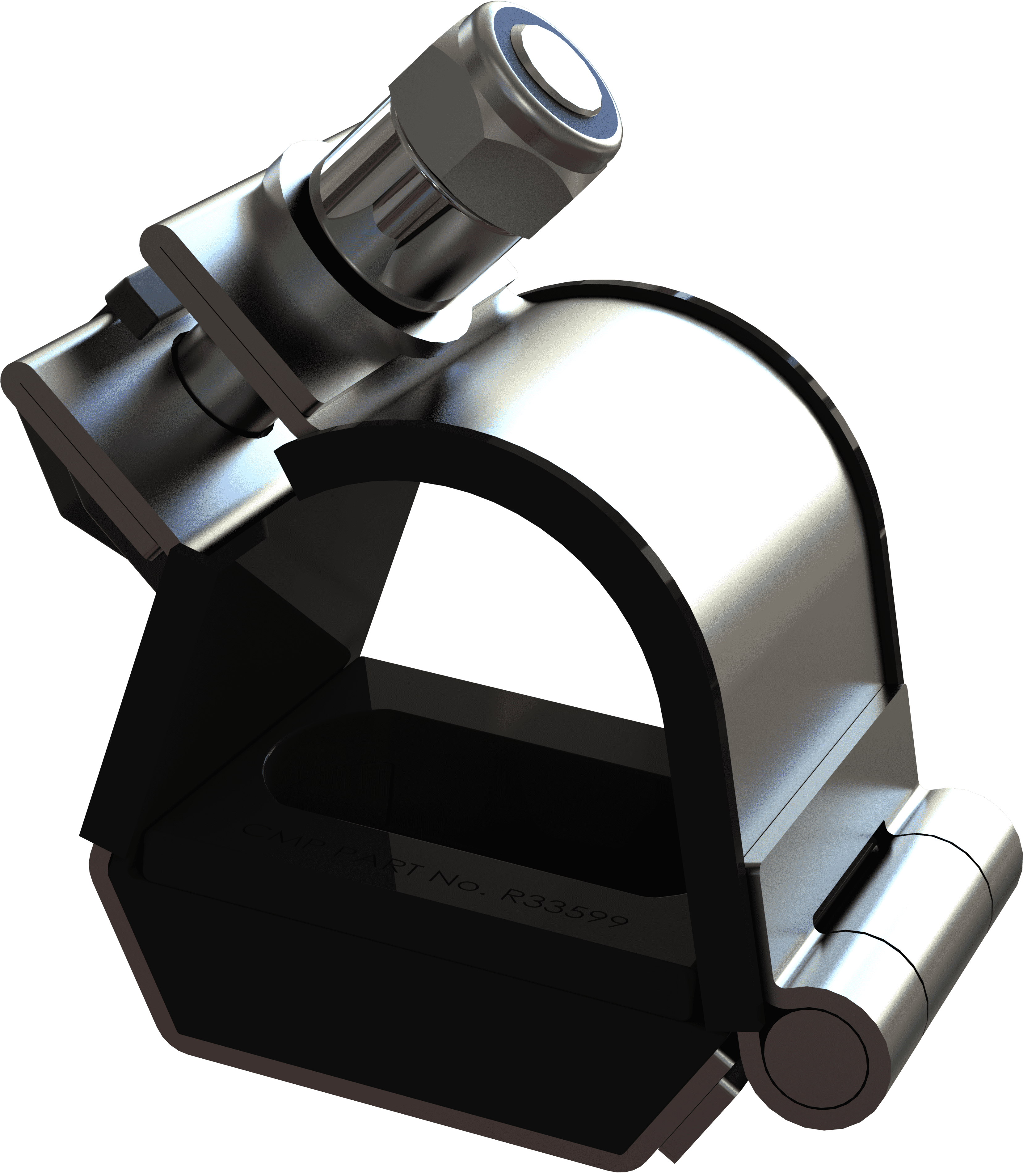

HDSS | Sovereign Cable Cleat

The CMP Sovereign is a trefoil composite cable cleat, designed and tested in accordance with IEC 61914. Manufactured from 316L Stainless Steel with Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric liners to protect the cable sheath. The cable cleat has been designed and tested for high short circuit fault withstand on cables held in trefoil formation, to ensure the securing and retention of cables without cable damage. The fully opening hinge allows the cable cleat to be opened wide for easy cable installation, and the single closing fixture with captive bolt ensures a quick installation. The two M10 and one M12 fixing clearance holes in the base allows versatility of fixing the cleat to the mounting structure.

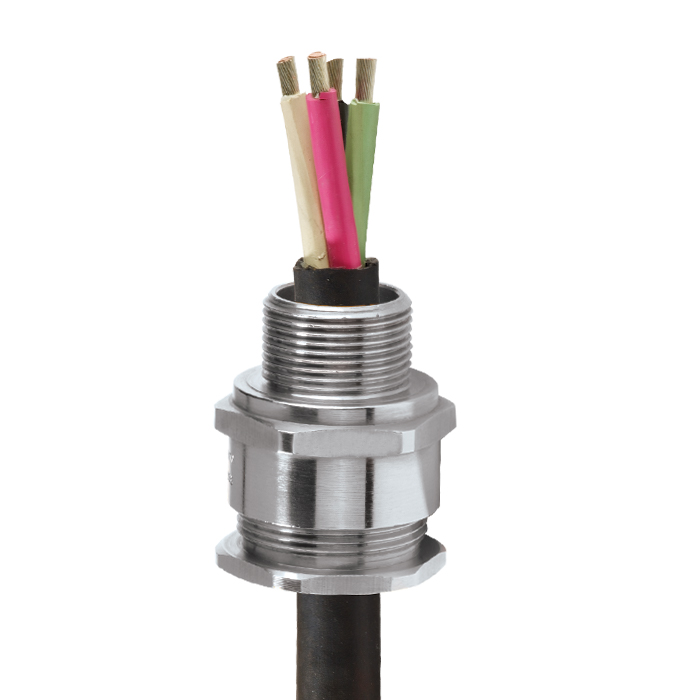

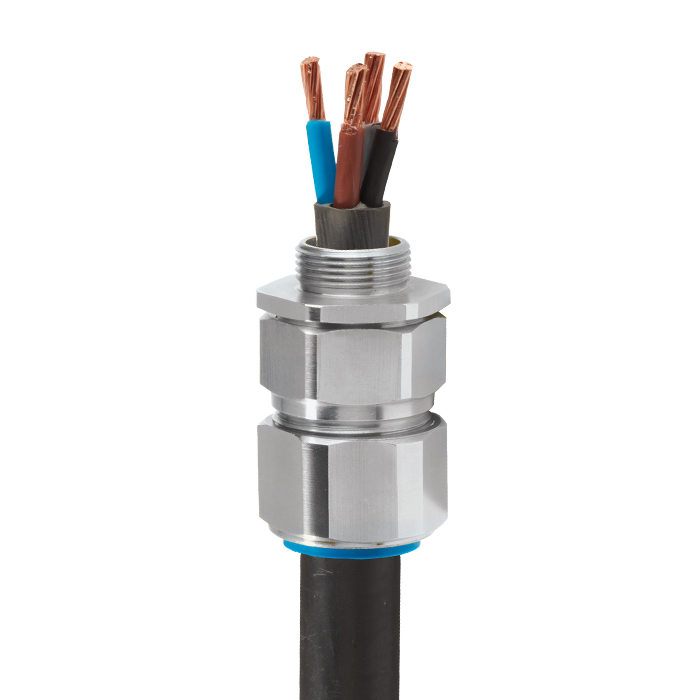

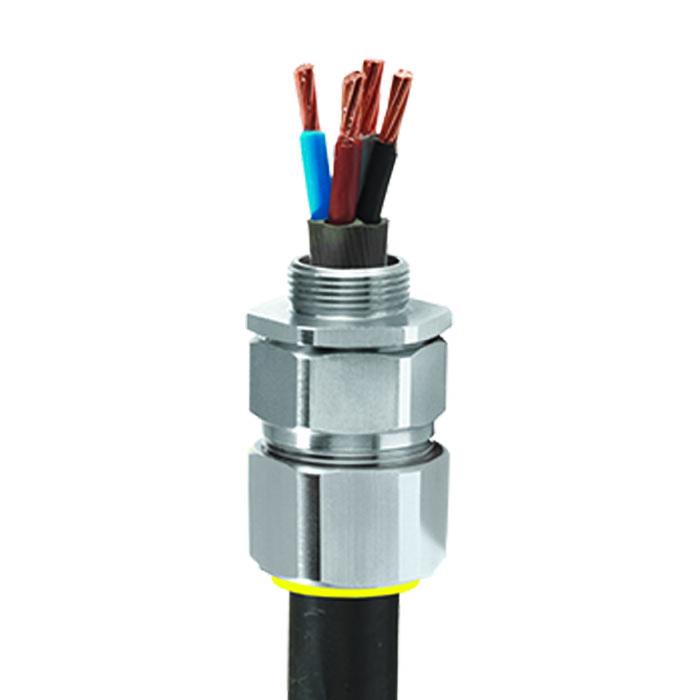

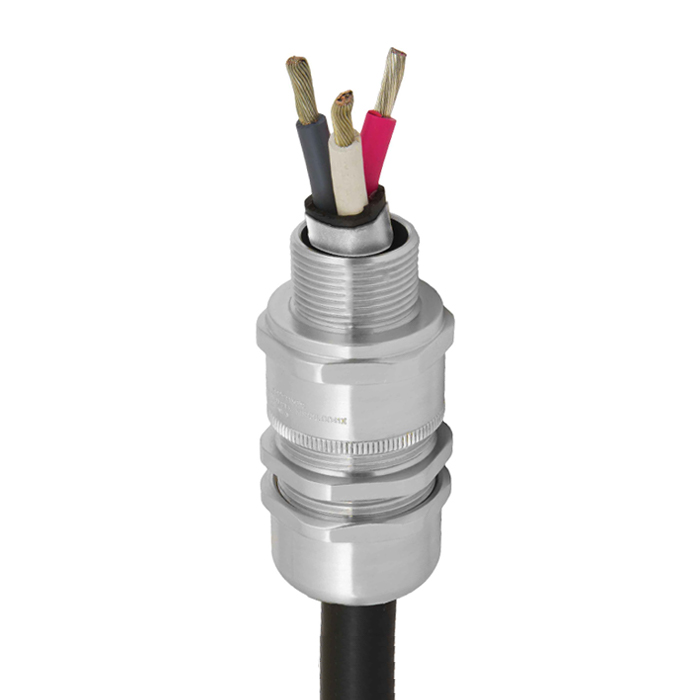

TSPe | TruSeal Cable Gland

The TSPe Ex i range of cable glands are for use in light / medium duty applications in Explosive Atmospheres. Designed to provide superior cable retention and strain relief.

TSPV0 | TruSeal Cable Gland

The TSPV0 range of cable glands are for use in light / medium duty applications in Industrial Areas (Safe Areas). Designed for use in public spaces where flame retardant halogen-free cables are typically required.

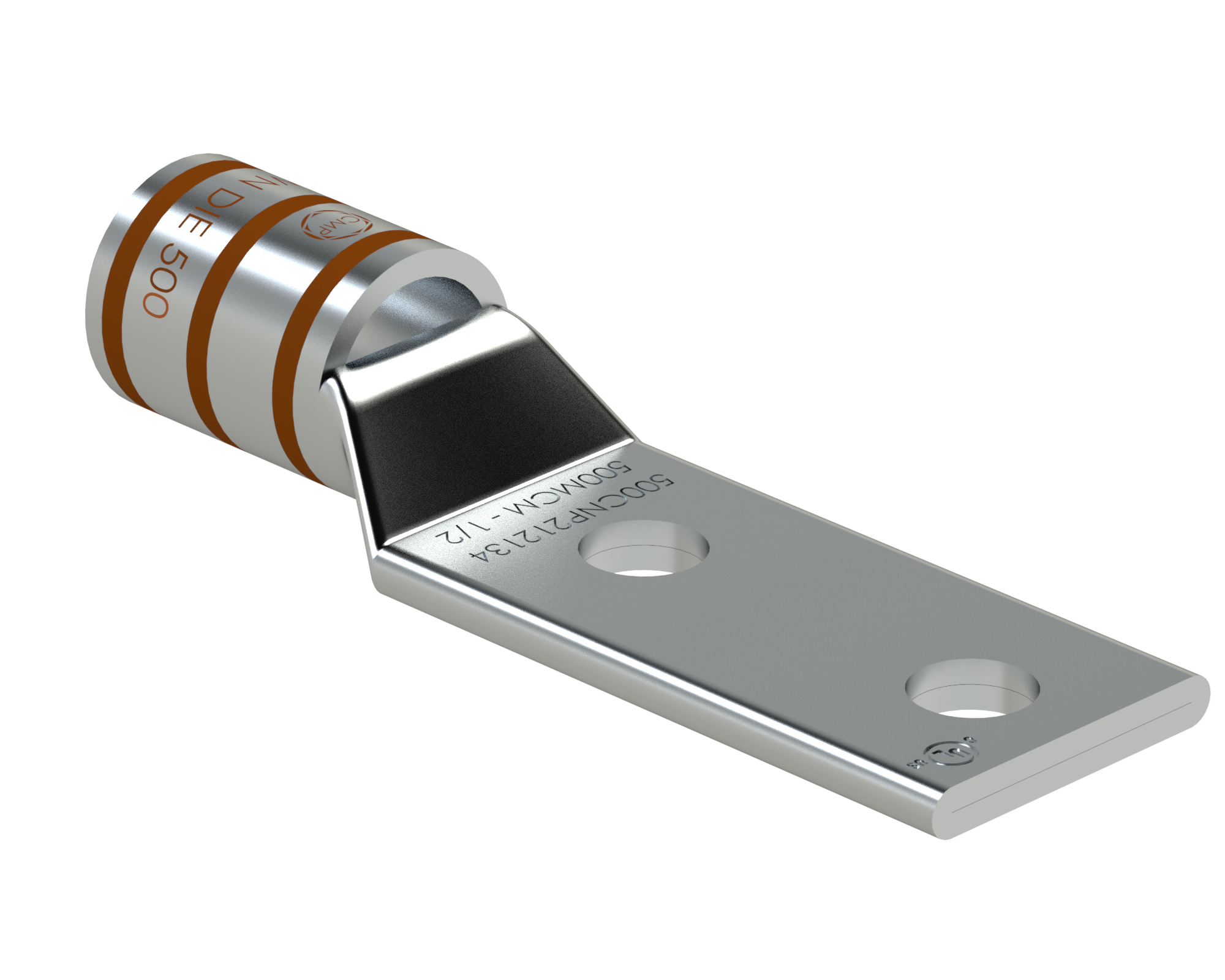

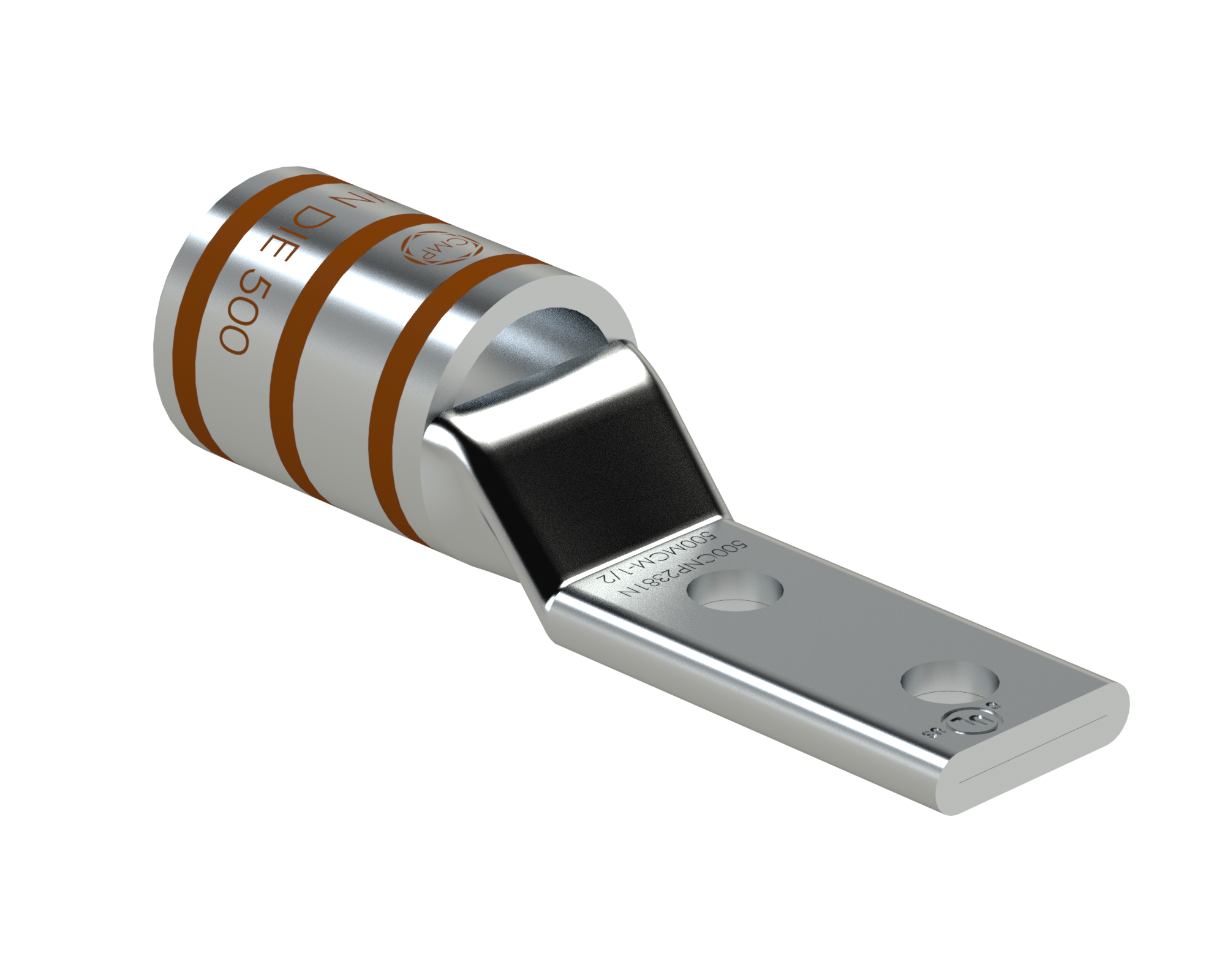

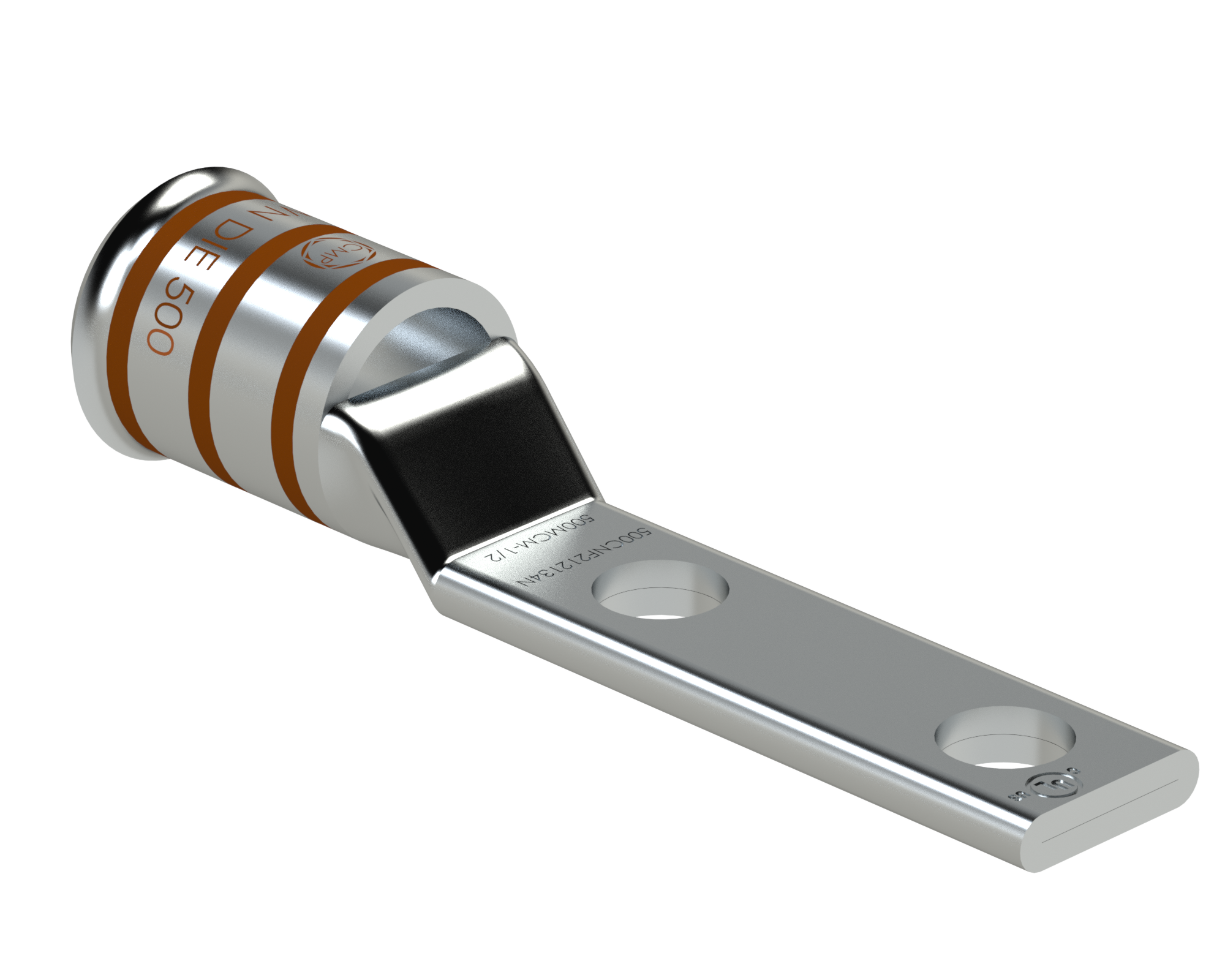

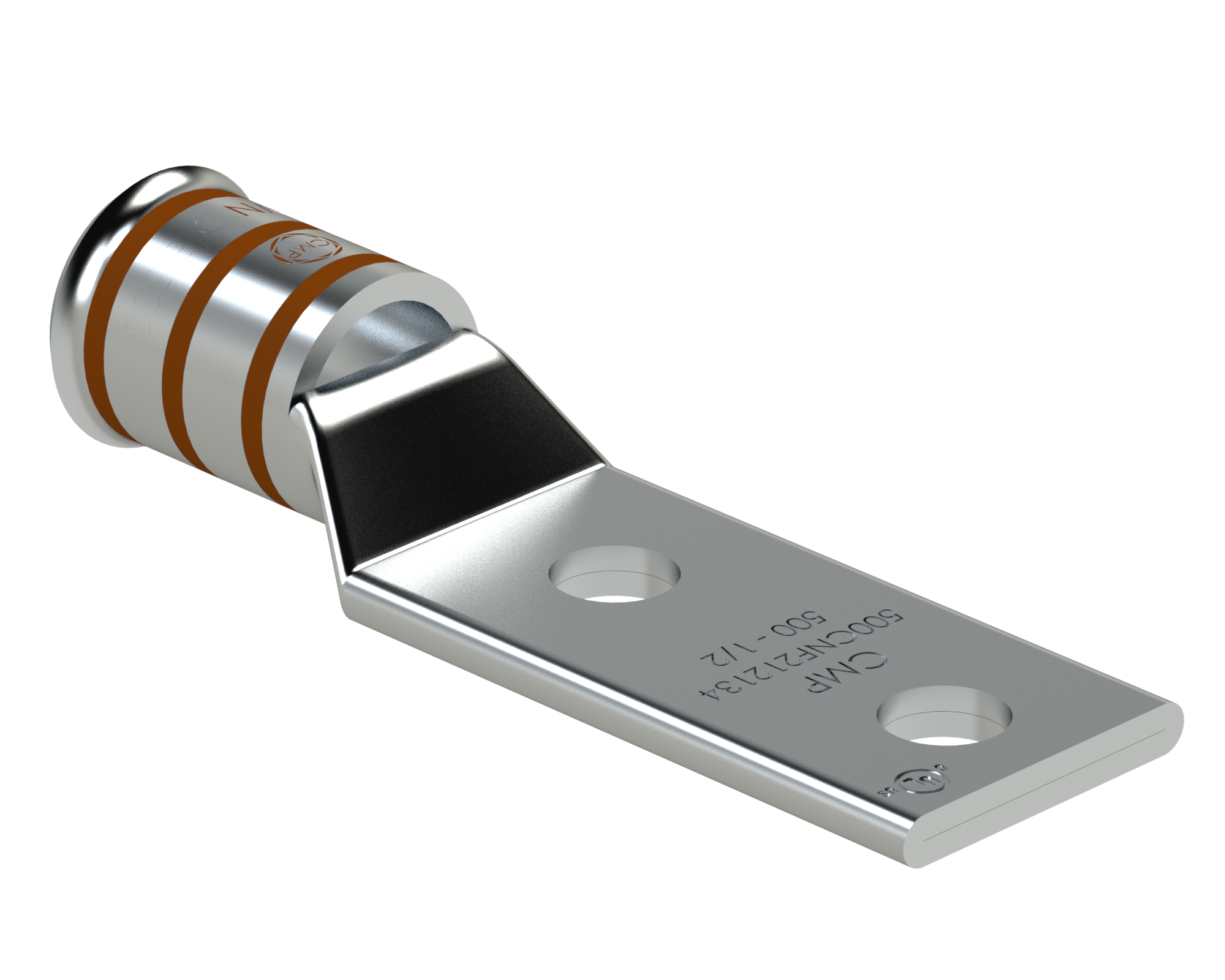

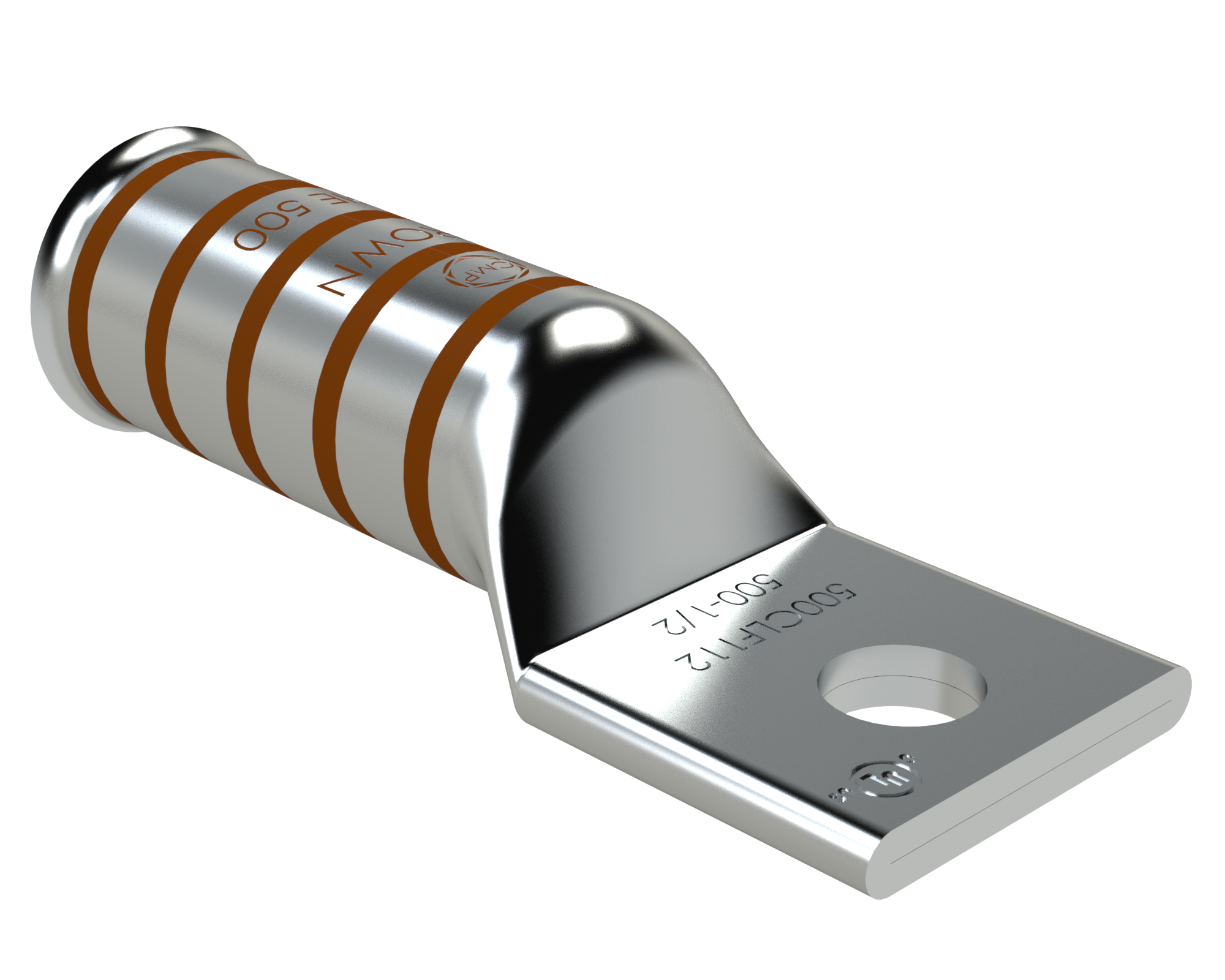

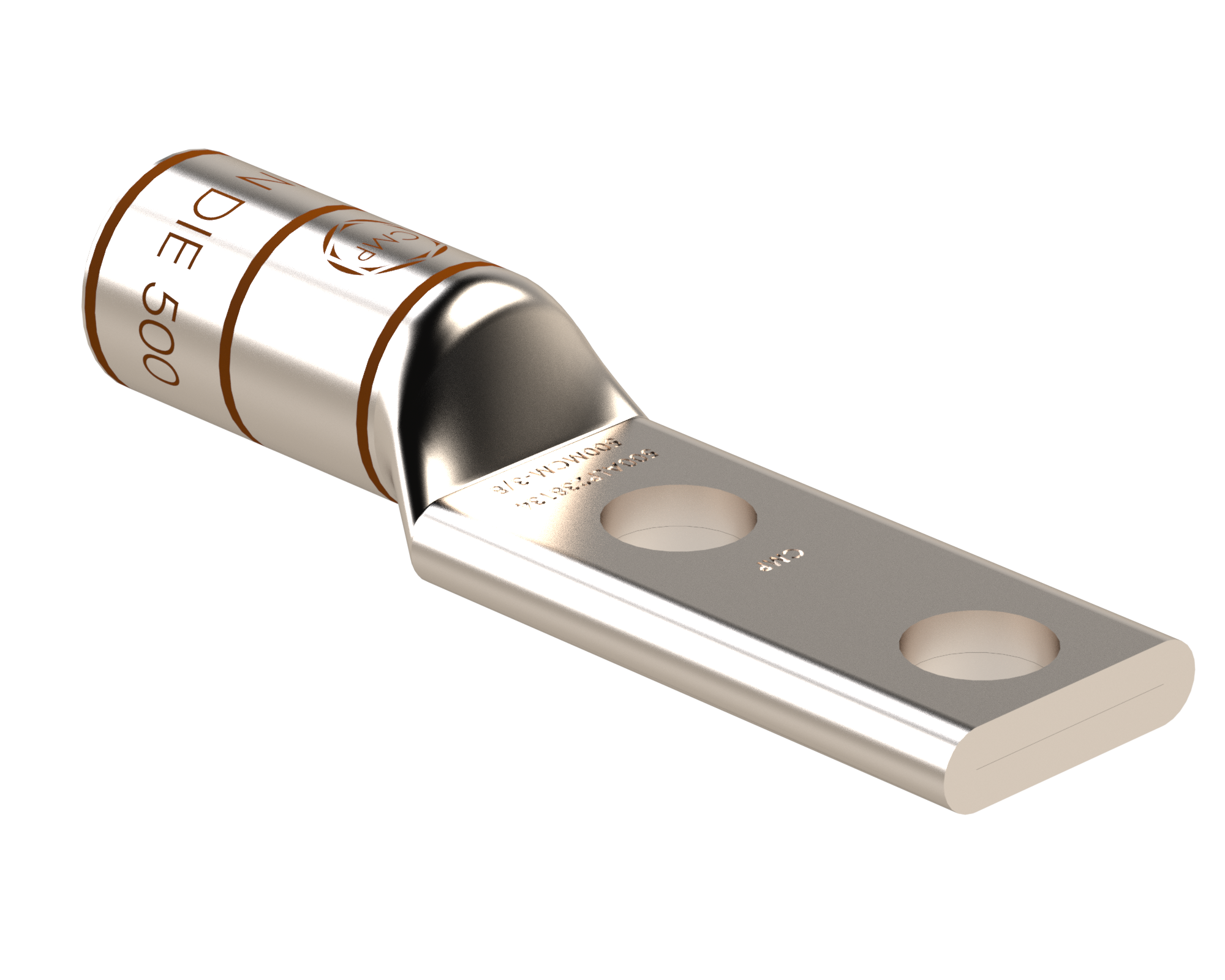

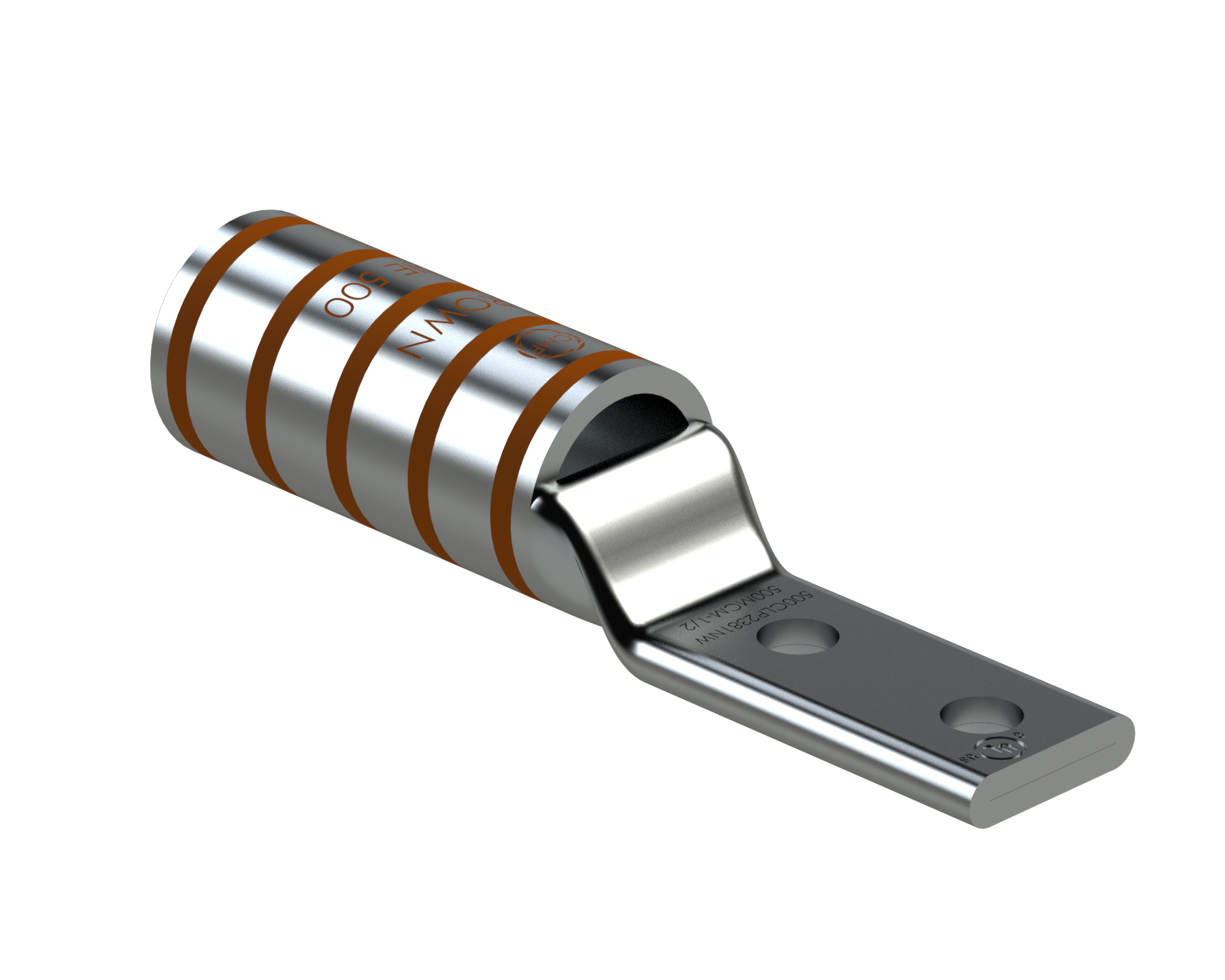

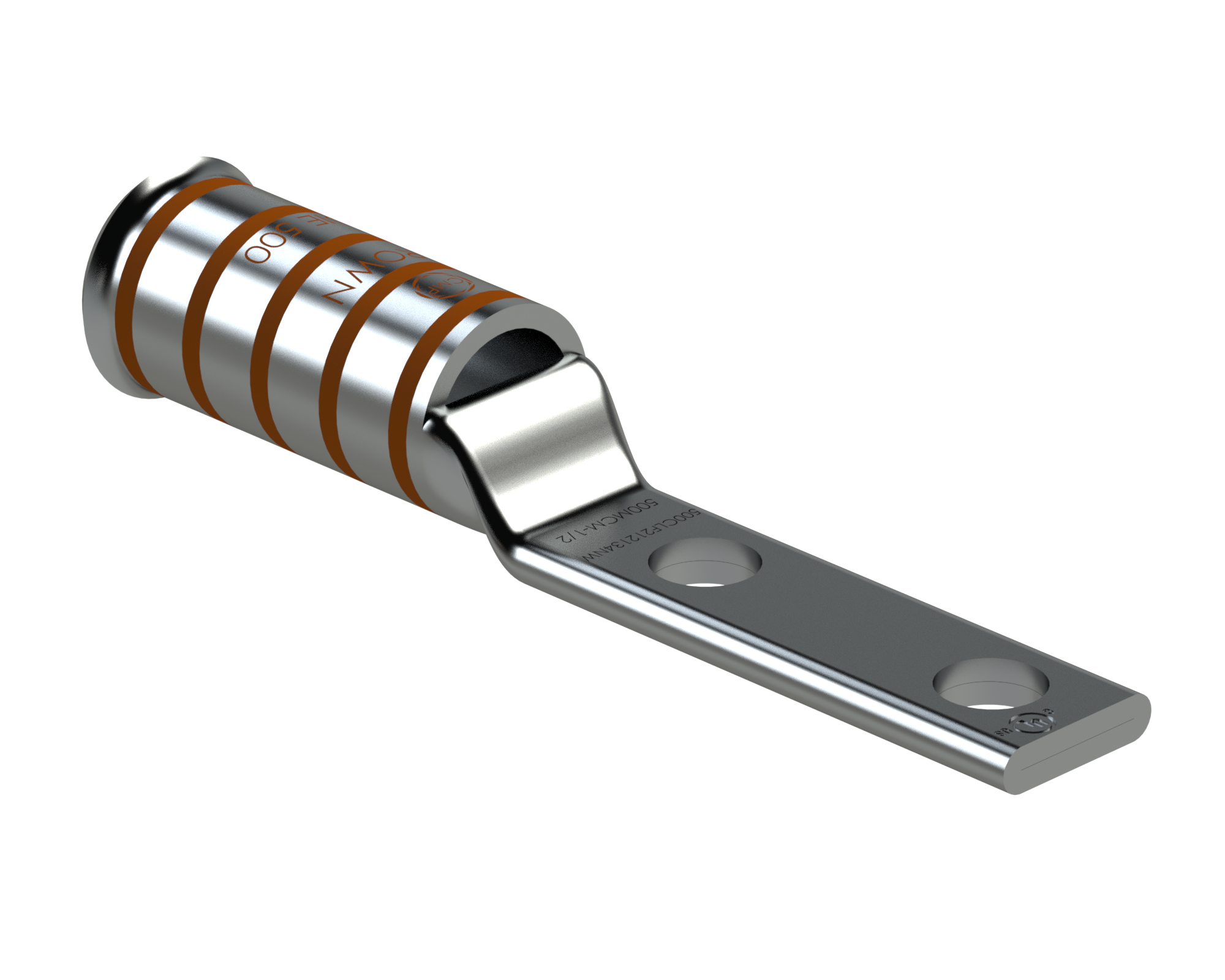

CNP2 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CHDF2 | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CHDF212X. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

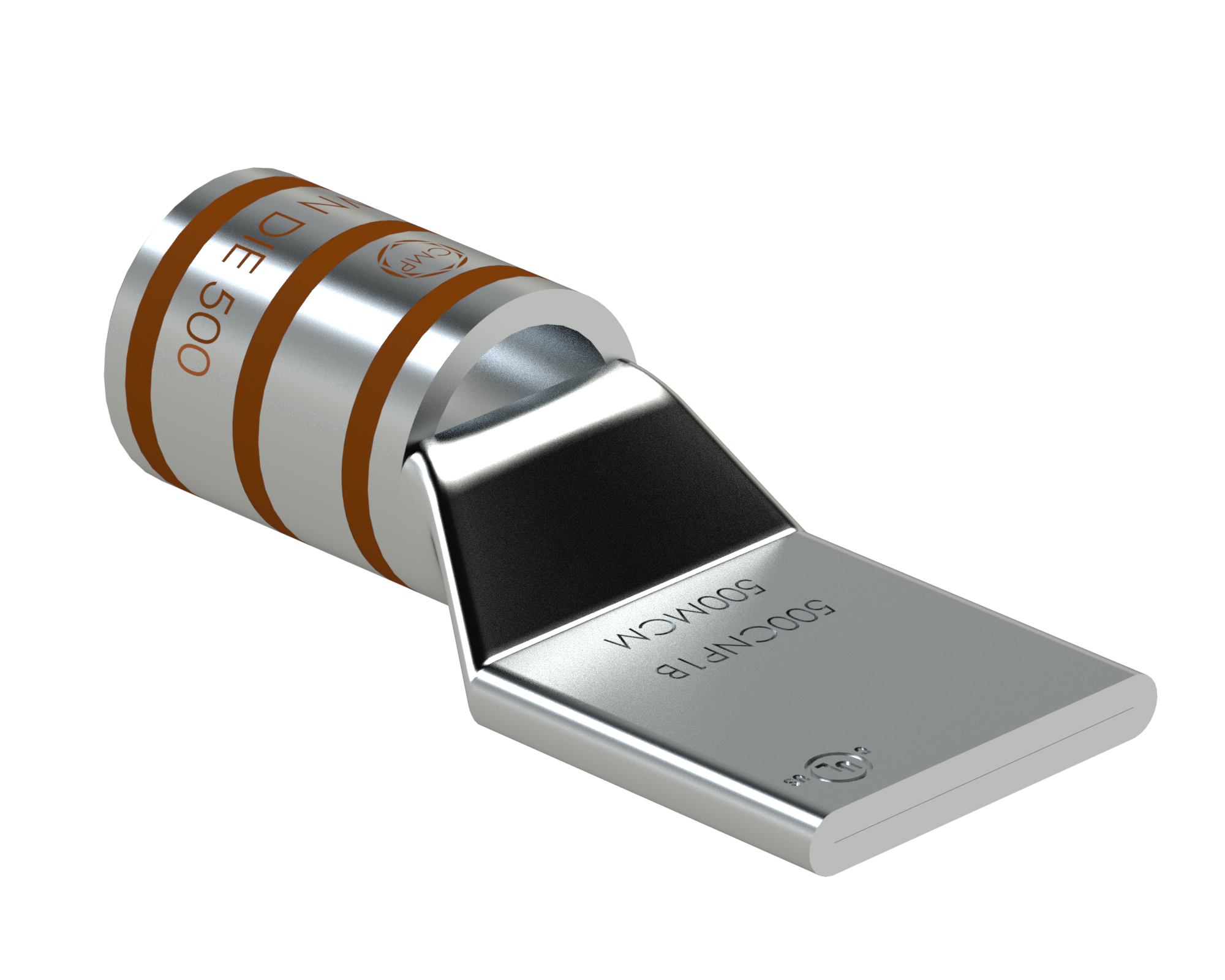

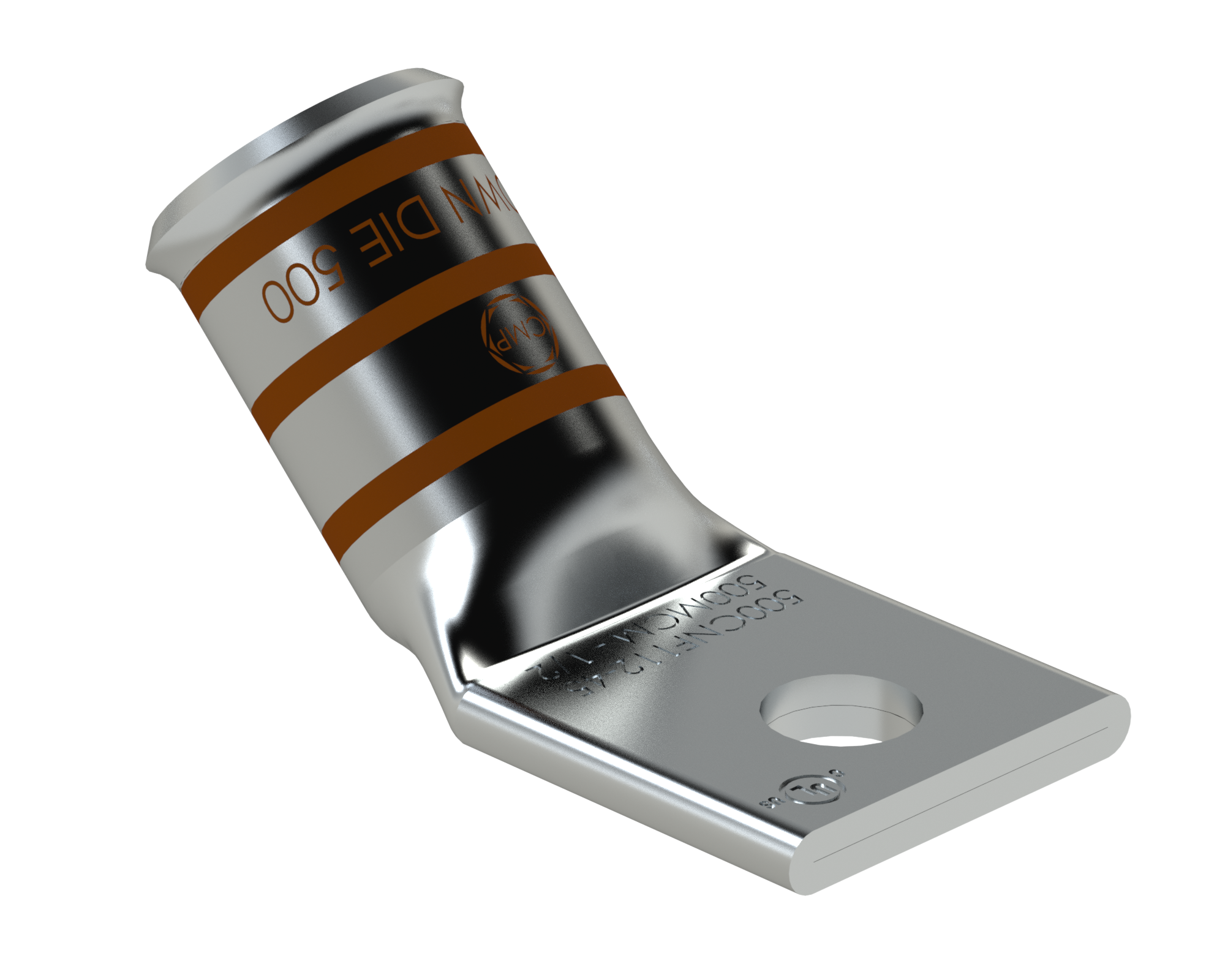

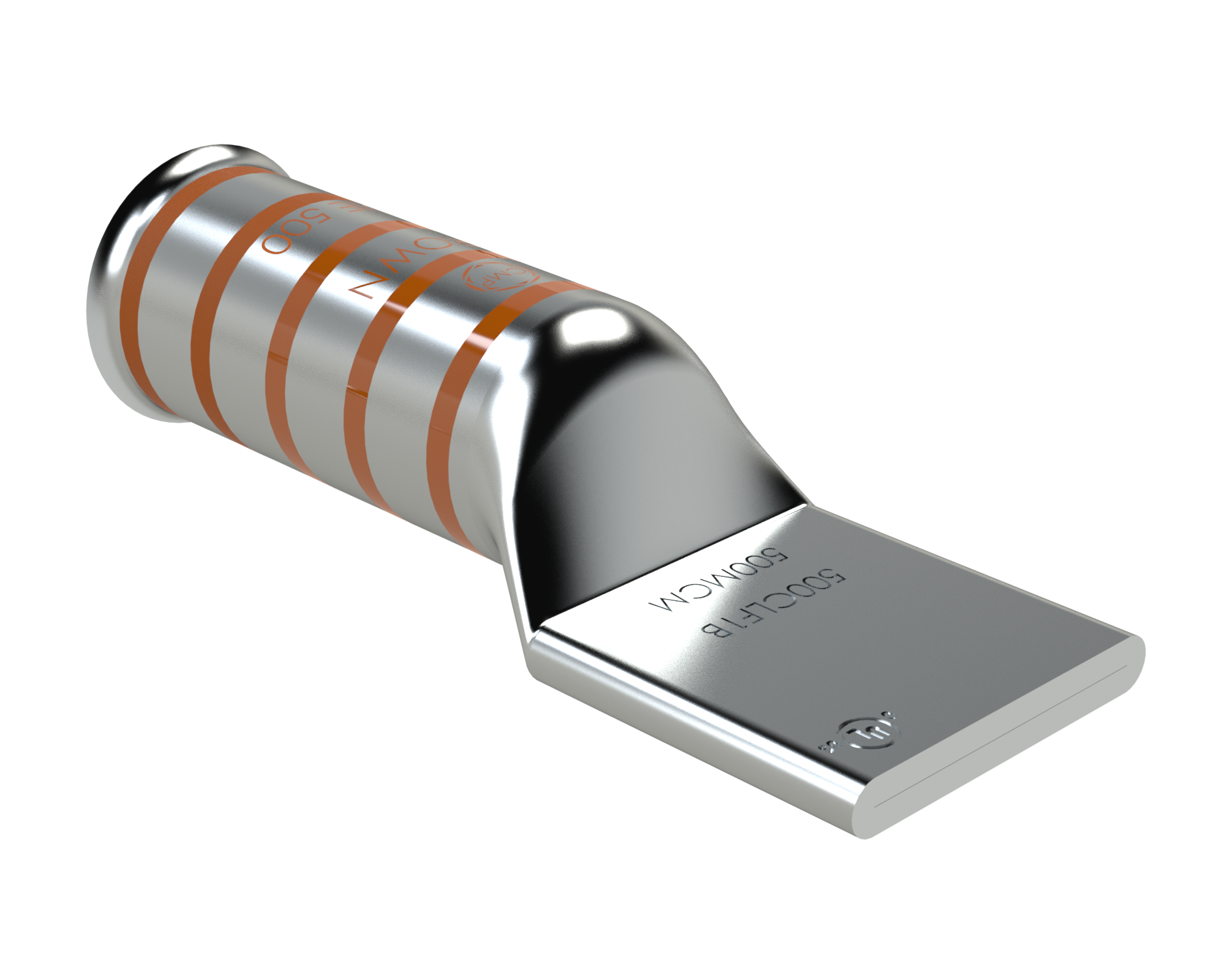

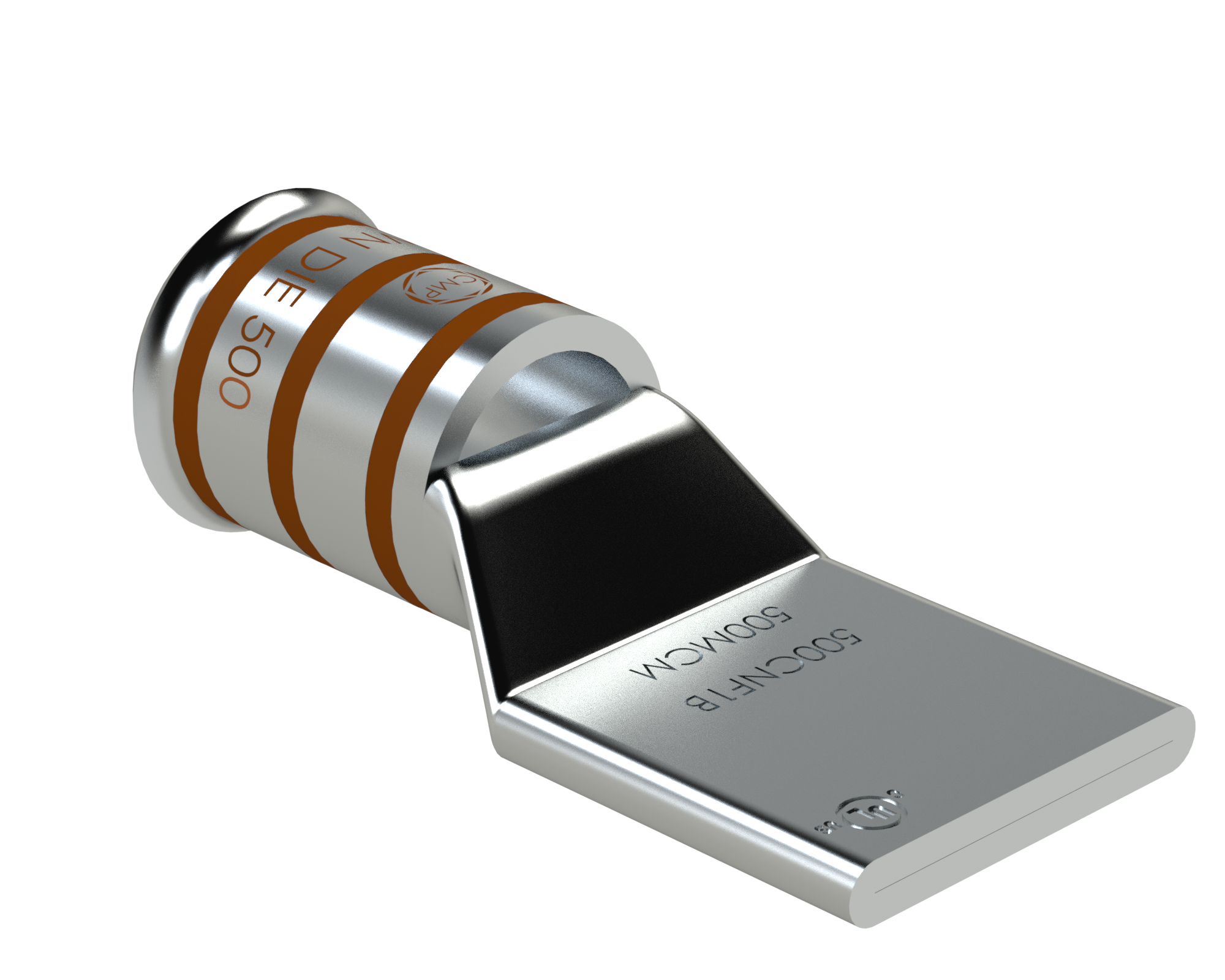

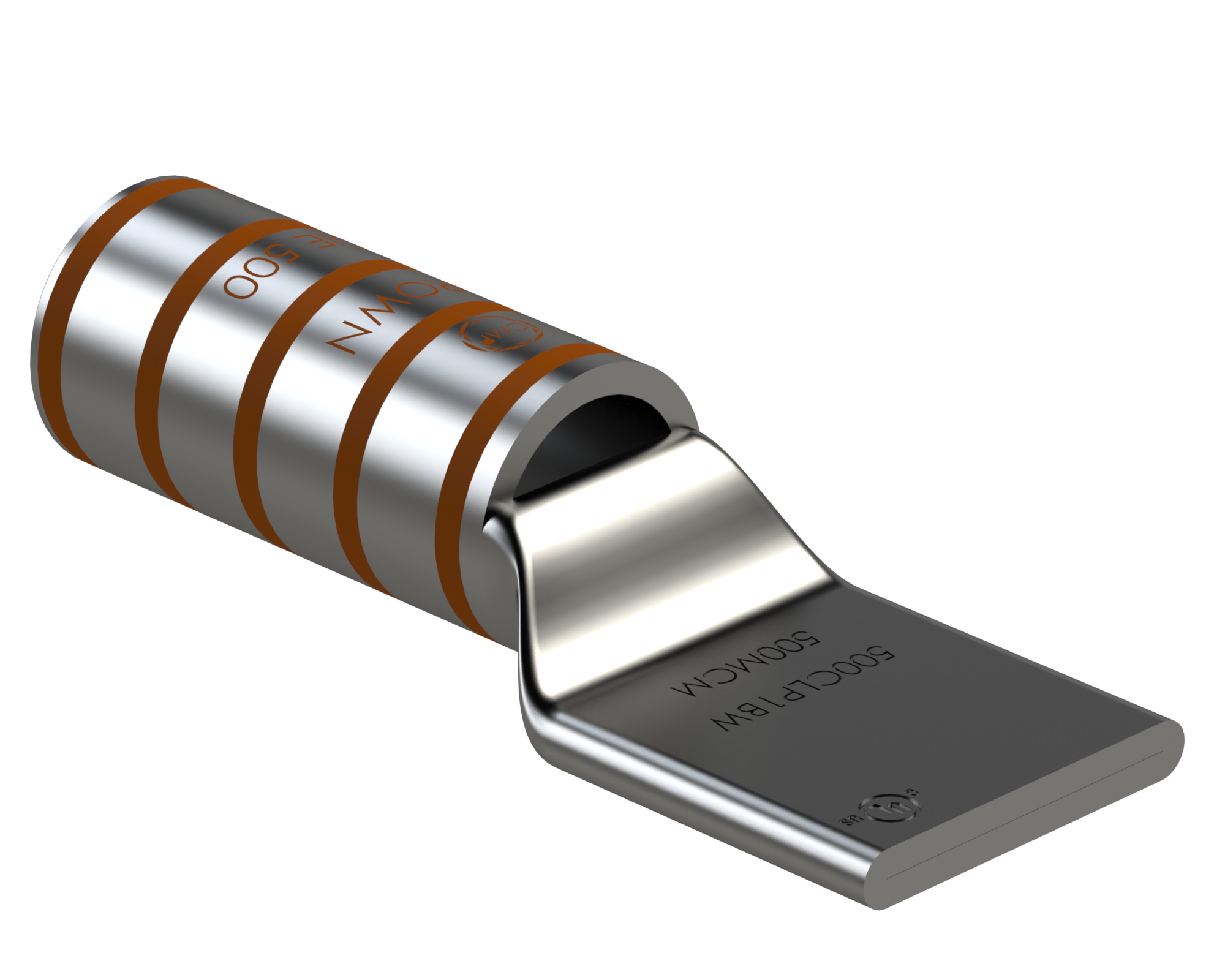

CNP1B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Blank palms enable custom stud hole drilling on installation, to suit connection requirements.

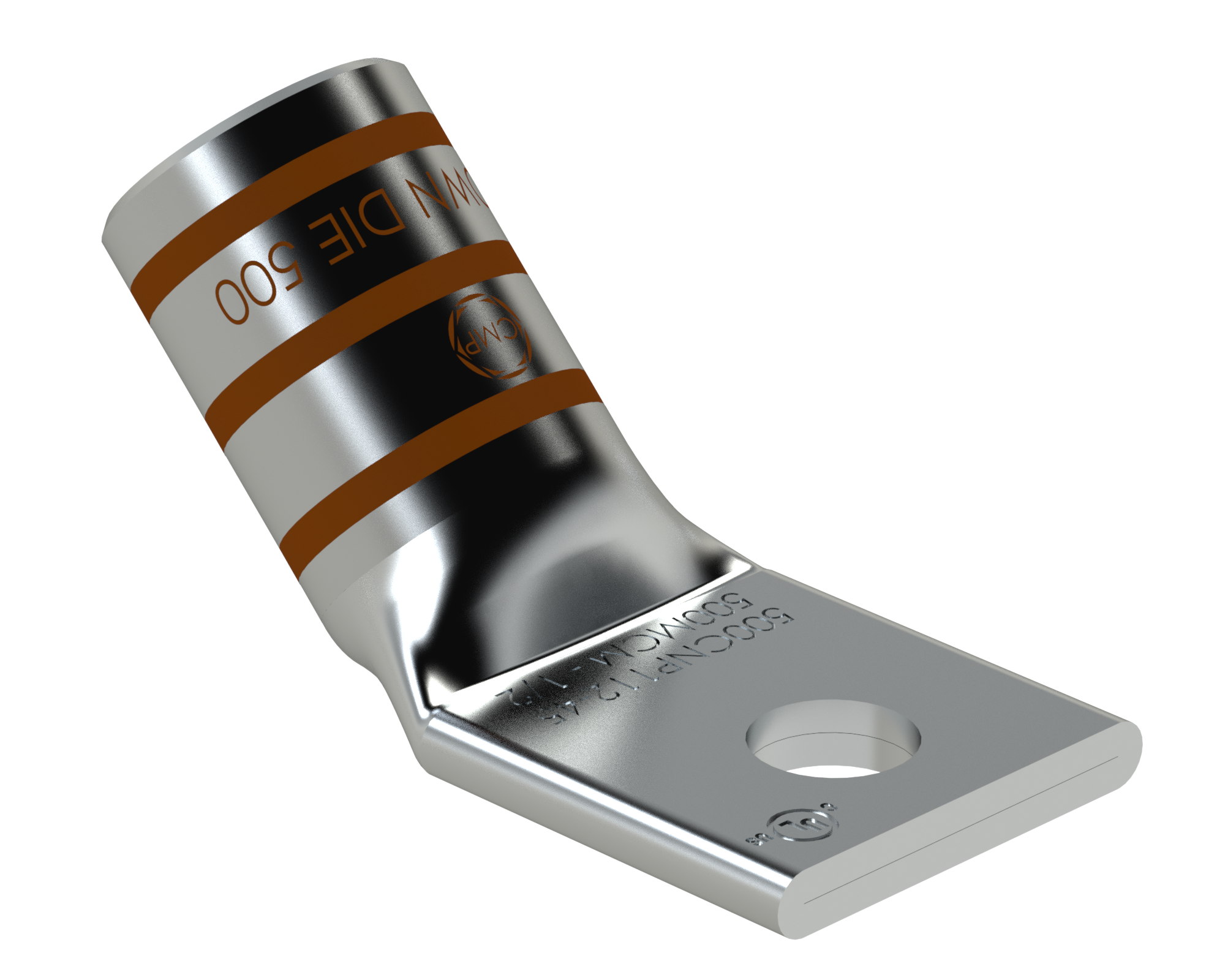

CNP1-45 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CHDP1 | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CHDP112X. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

CHDF1 | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CHDF112X. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

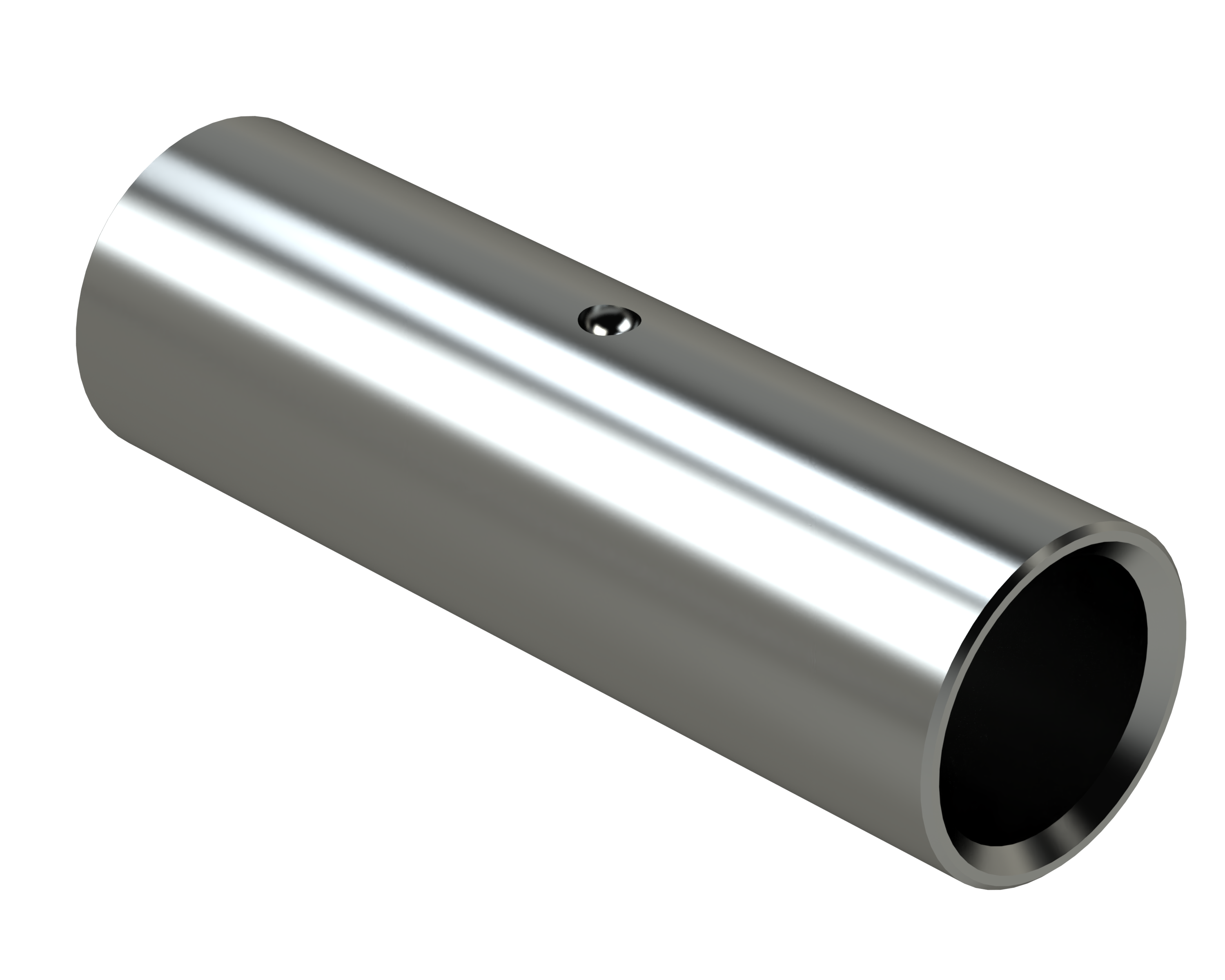

CSP | Cable Splice (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

CSDN | DIN Cable Splice Cable Lug

CMP DIN Copper Compression Splices have been designed to match the dimensions of DIN 46267 for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

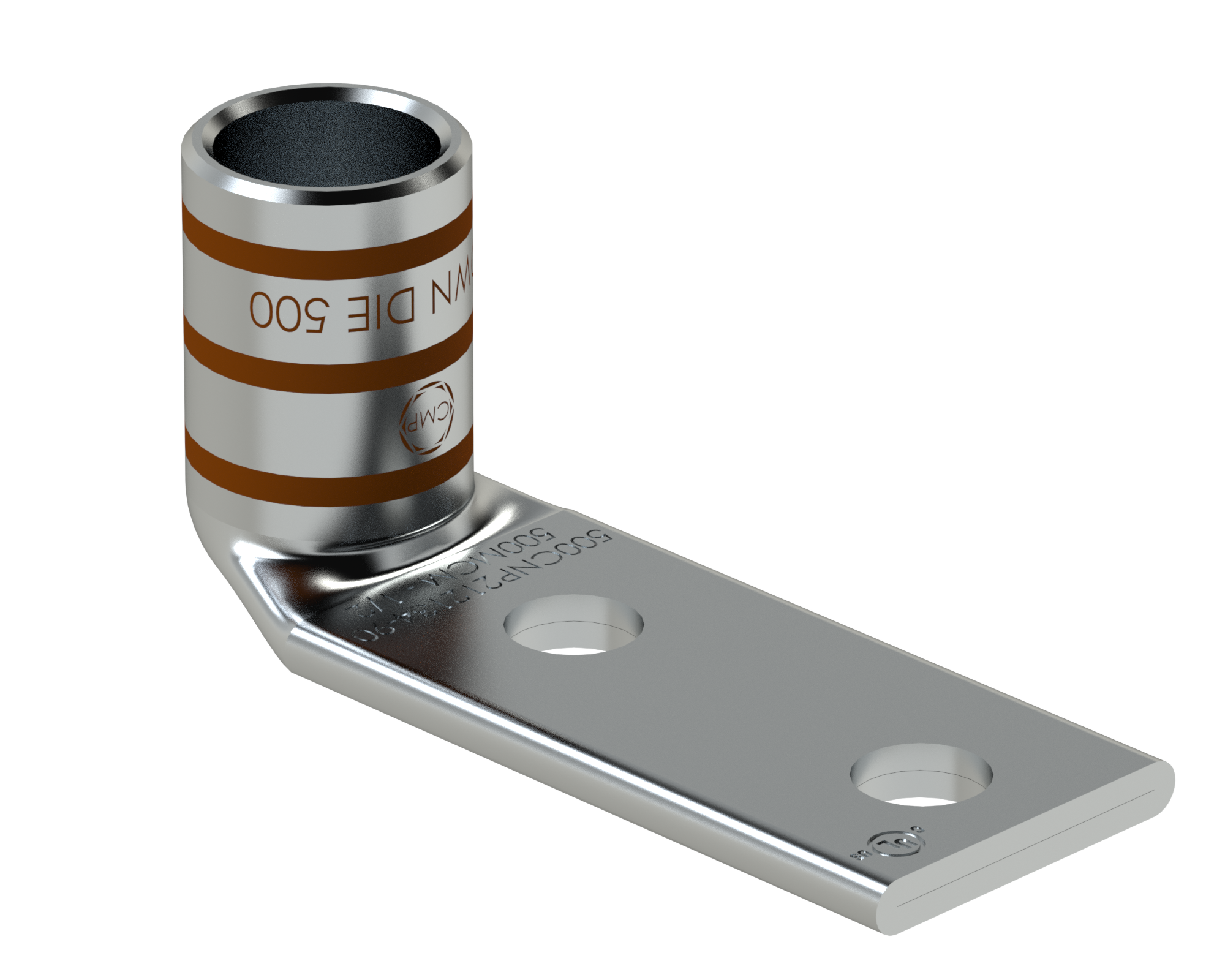

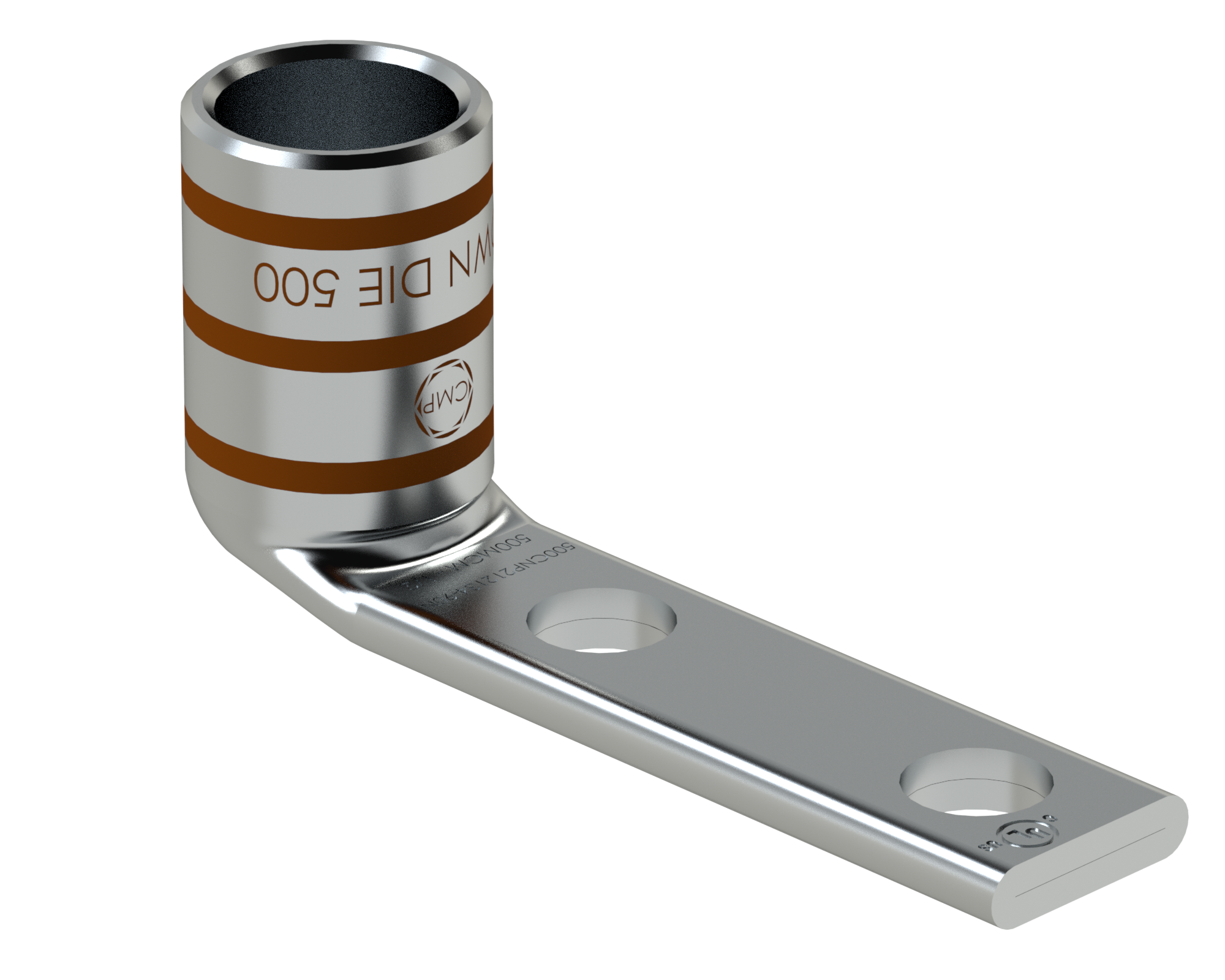

CNP2-90 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNP2-45 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNP1-45N | Imperial Cable Lug Cable Lug

These products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

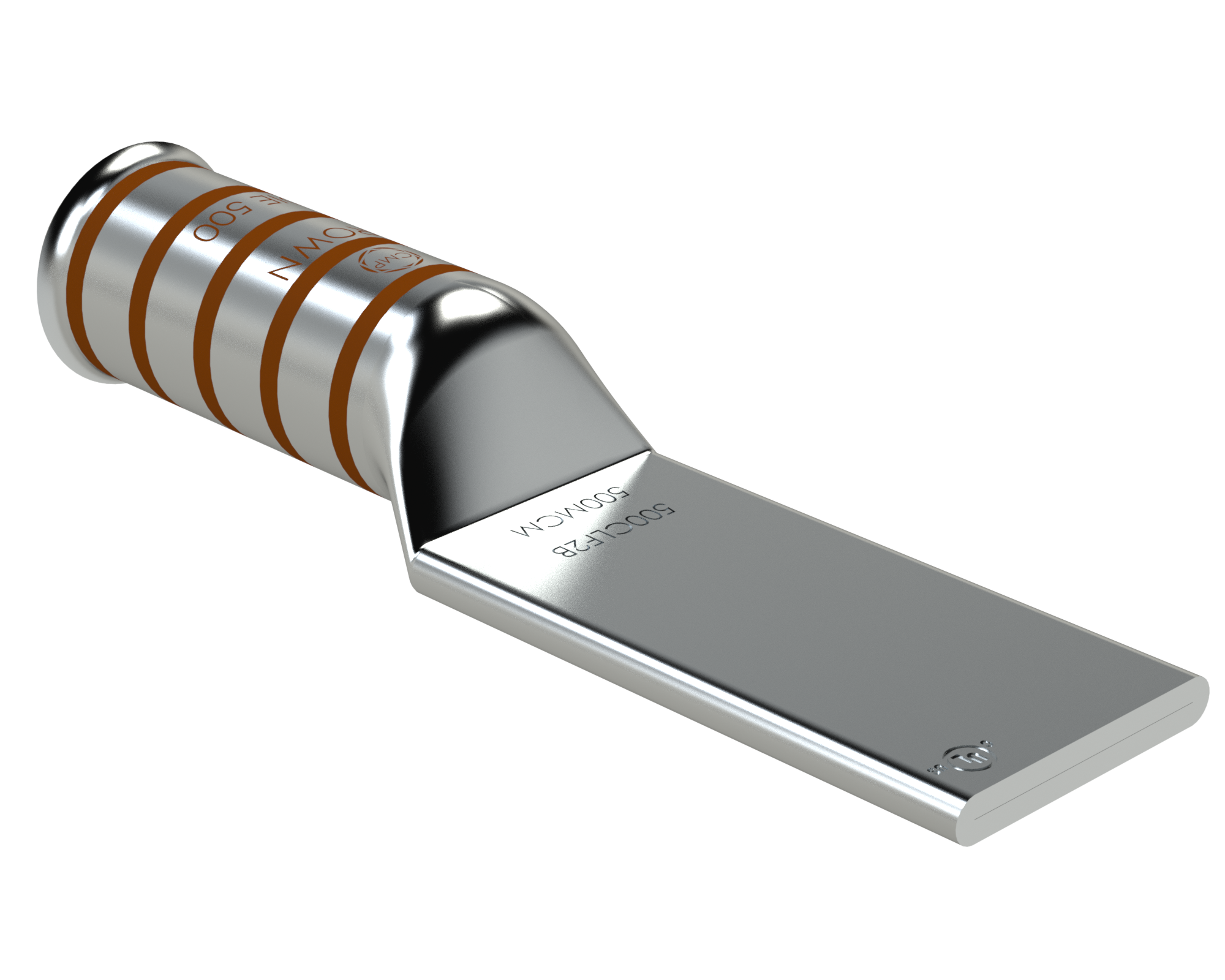

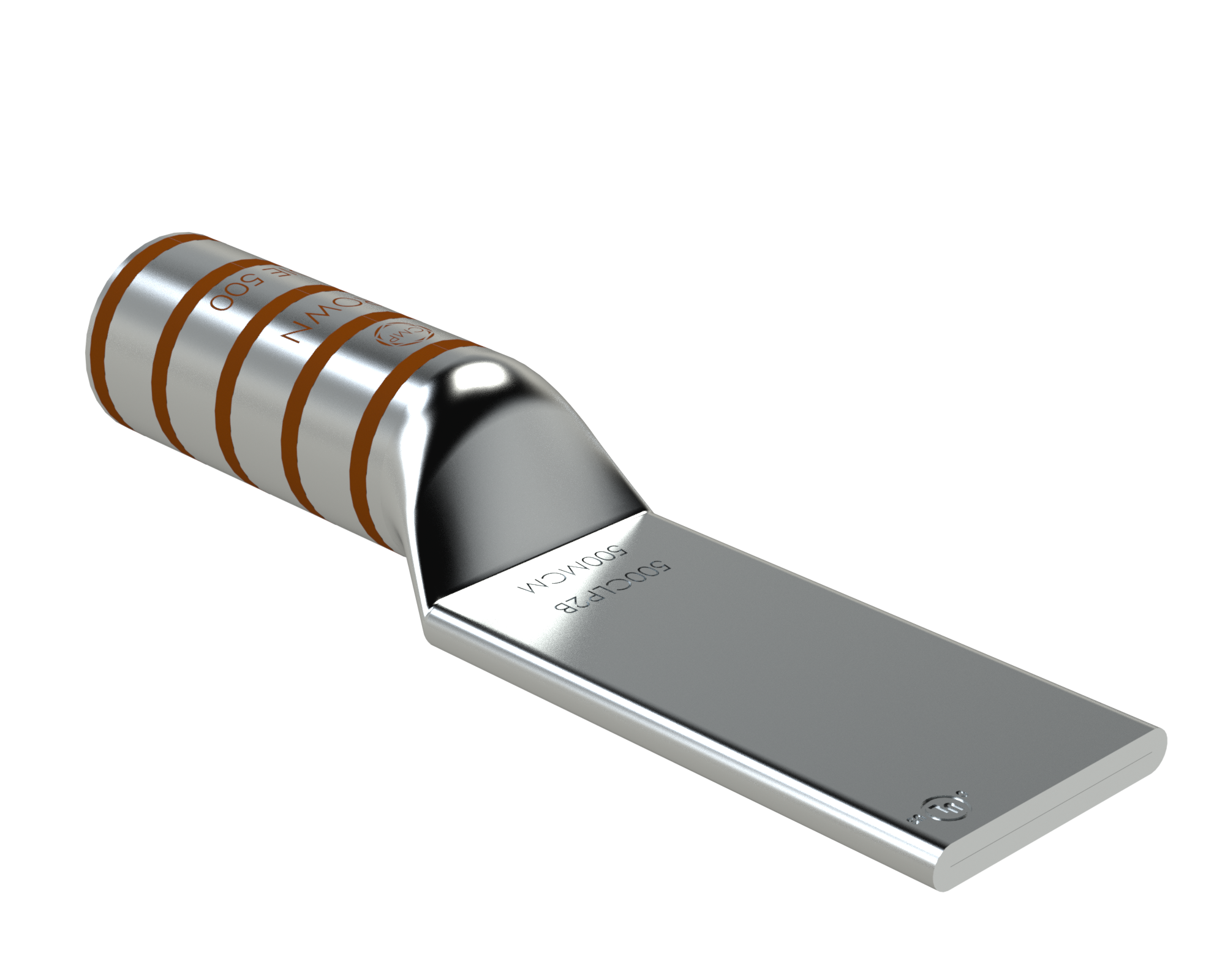

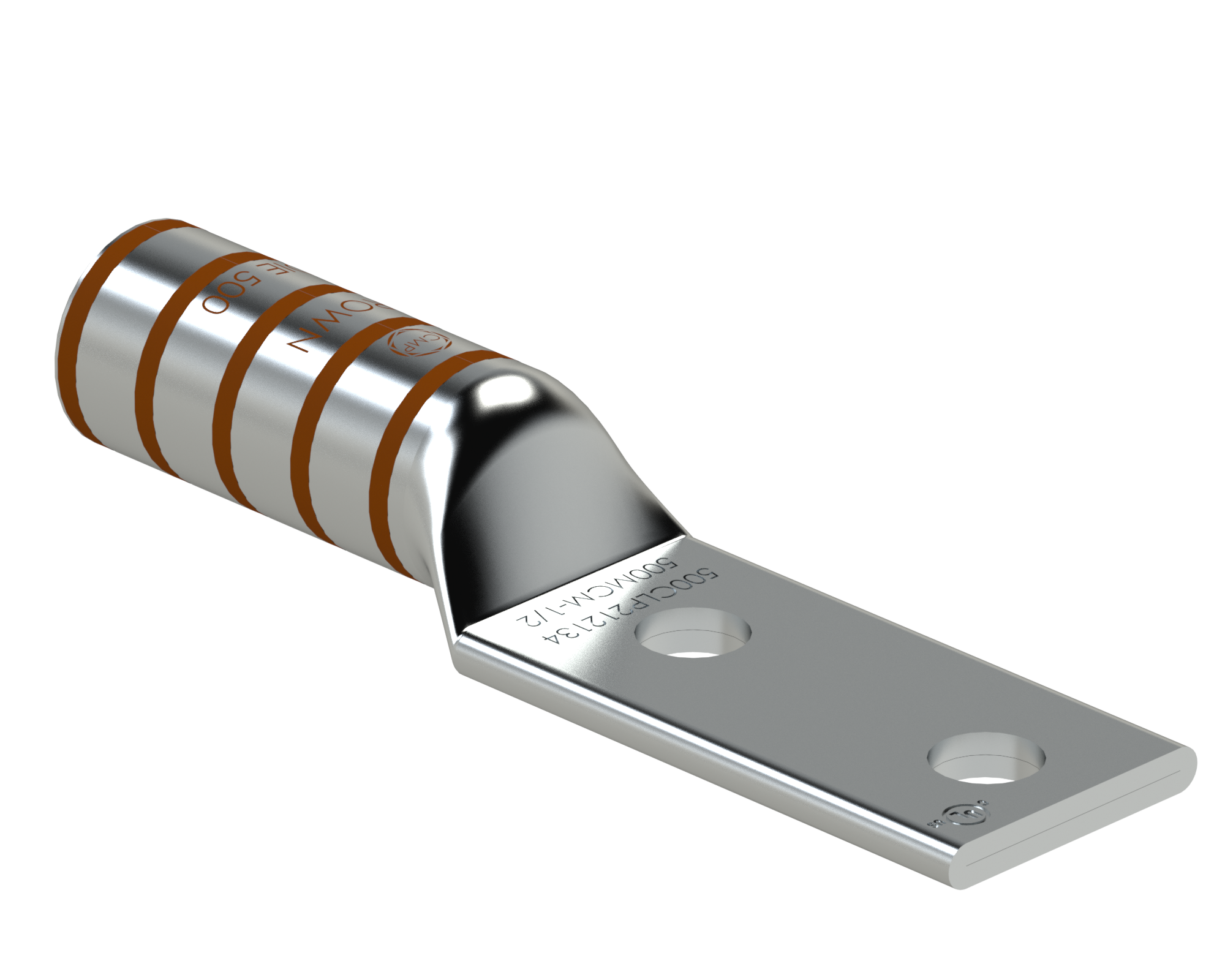

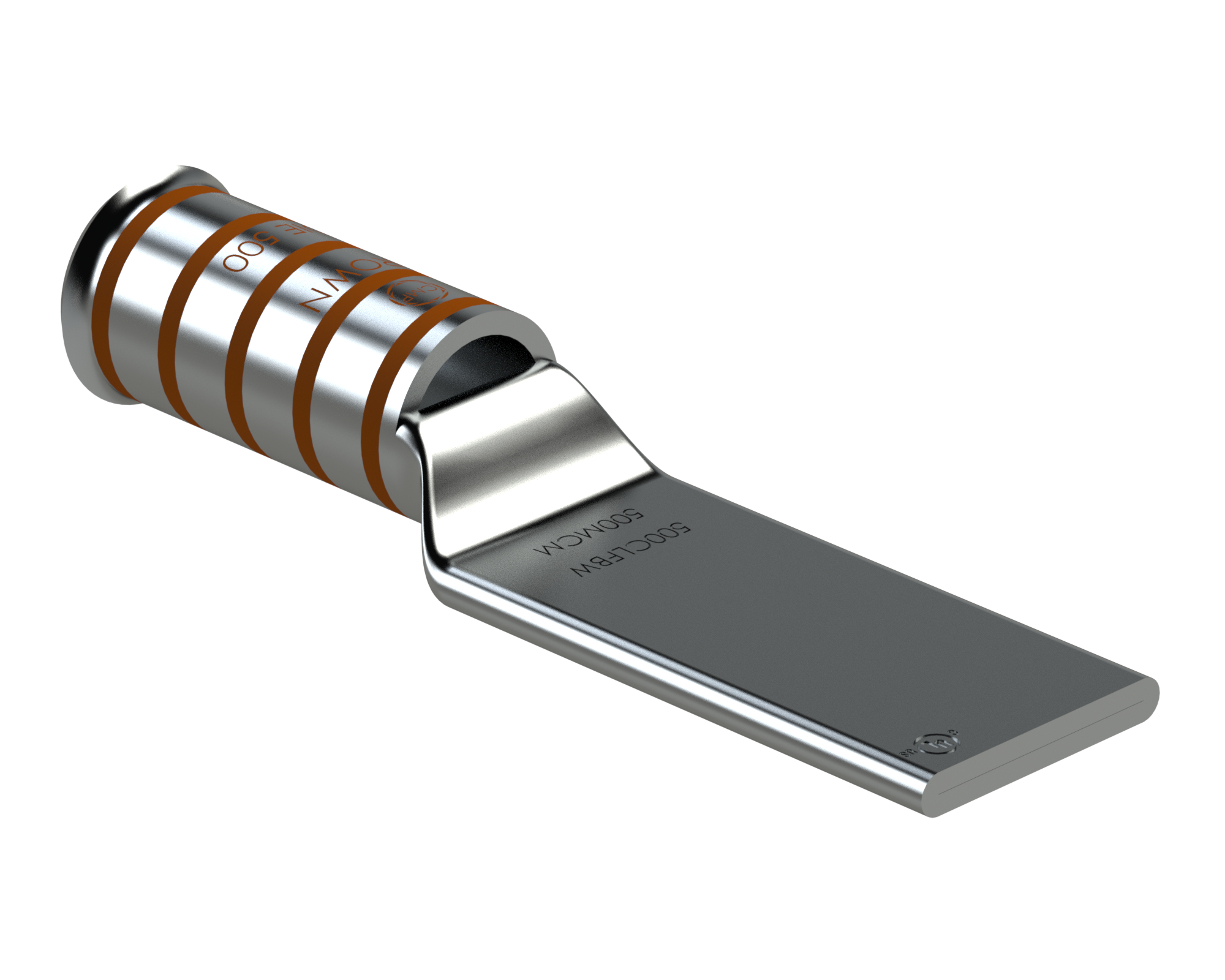

CLF2B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLF2BW. Long, blank palms enable custom stud hole drilling on installation, to suit connection requirements.

CNP1-90 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNF1-45 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNF1-90 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CSDF1 | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class B, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is an inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CSDF112X. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

CNP2-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNP1-90N | Imperial Cable Lug Cable Lug

These products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNP1-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

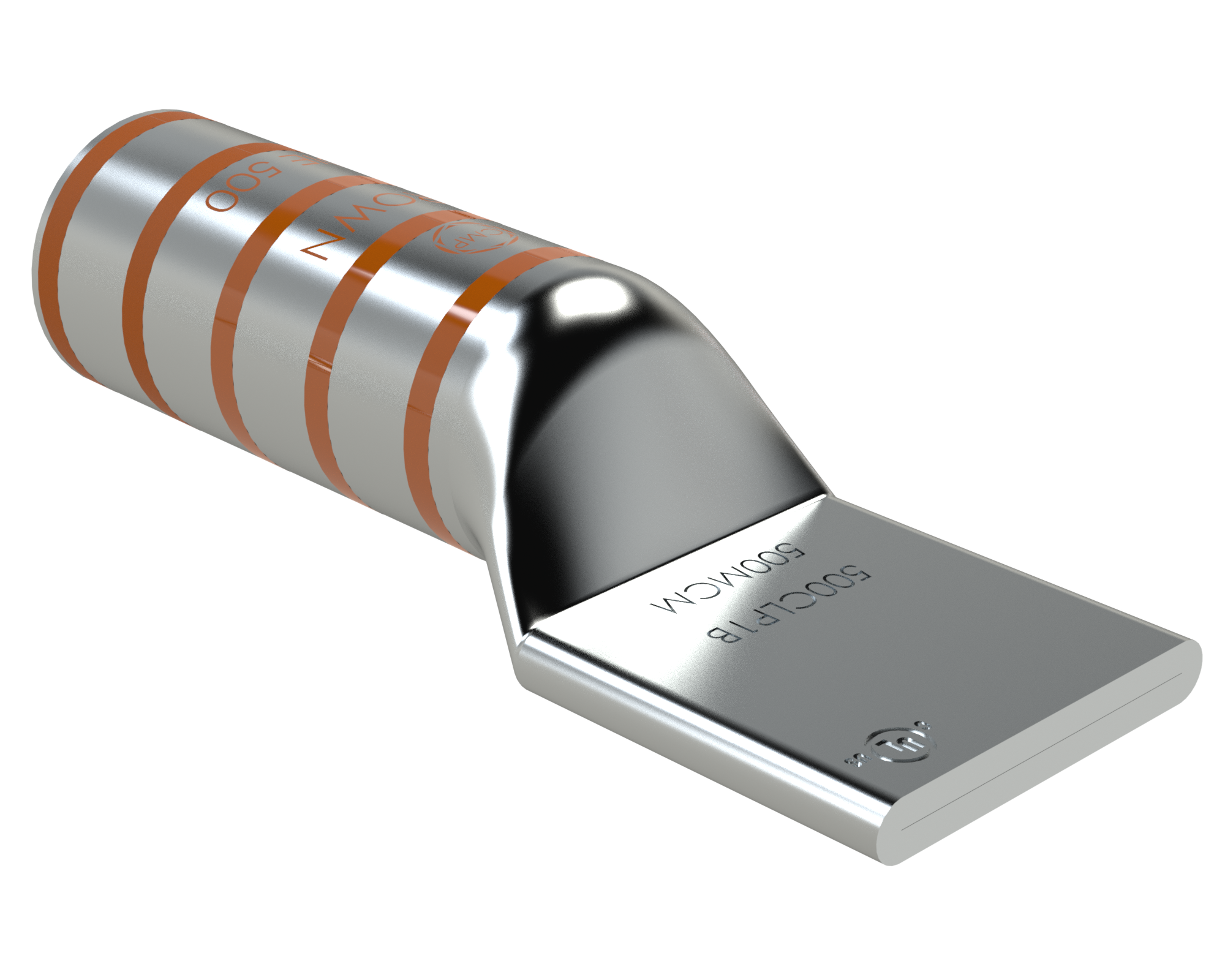

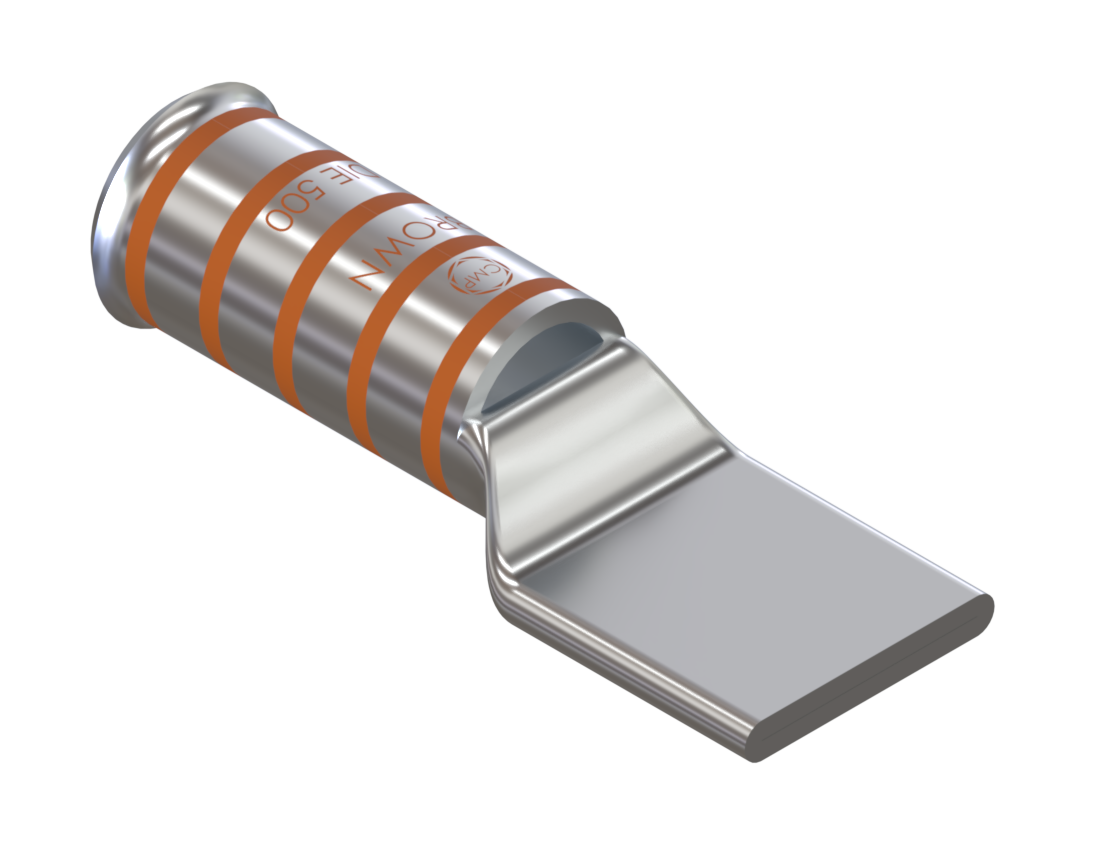

CLF1B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLF1BW. Blank palms enable custom stud hole drilling on installation, to suit connection requirements.

CNF2-45N | Imperial Cable Lug Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNF2-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNF2-90 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNF2-45 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNF1-90N | Imperial Cable Lug Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNF1-45N | Imperial Cable Lug Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNF1-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CLF2-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLF2-NW. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CLP2-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLP2-NW. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CLF1-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLF1-NW. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

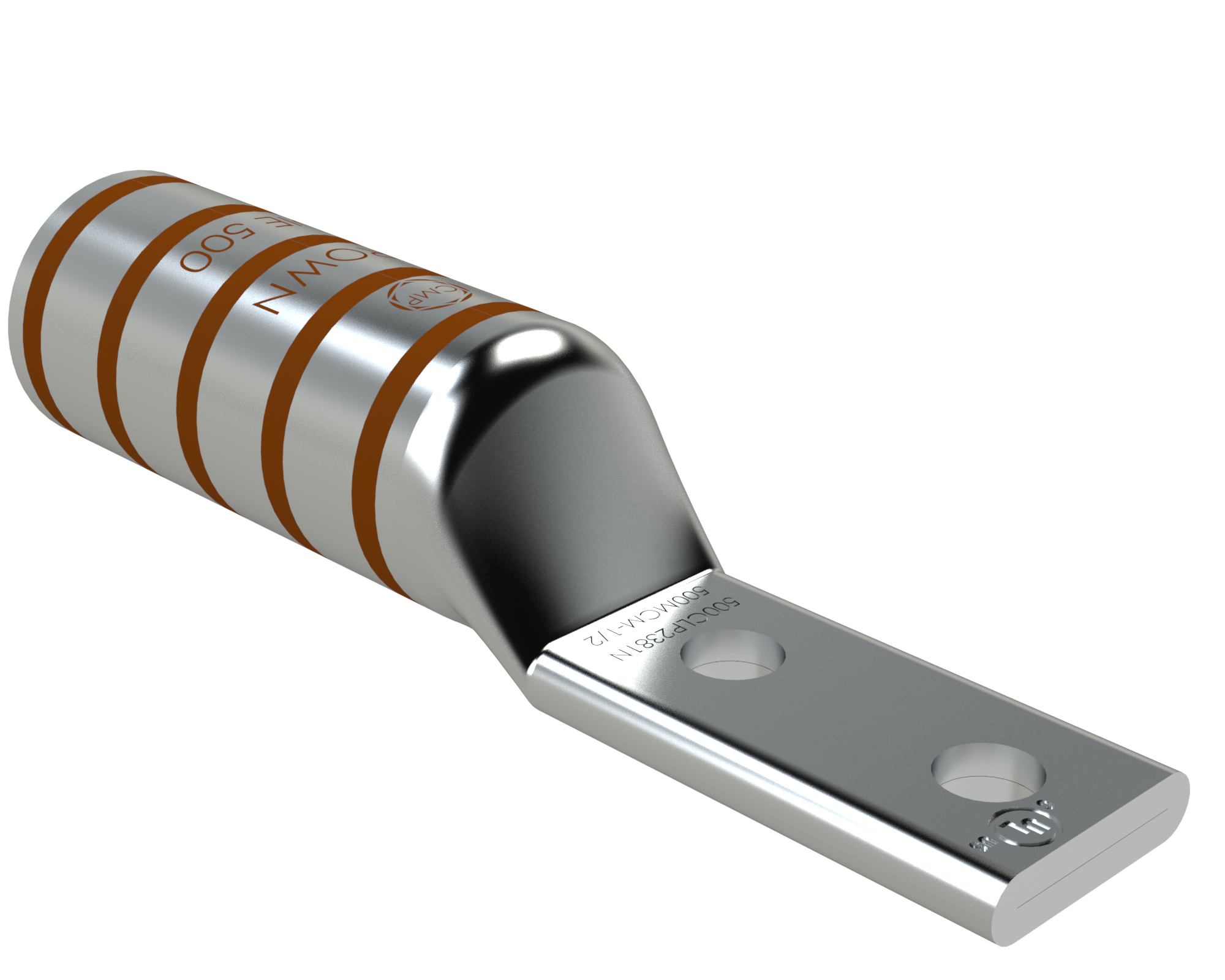

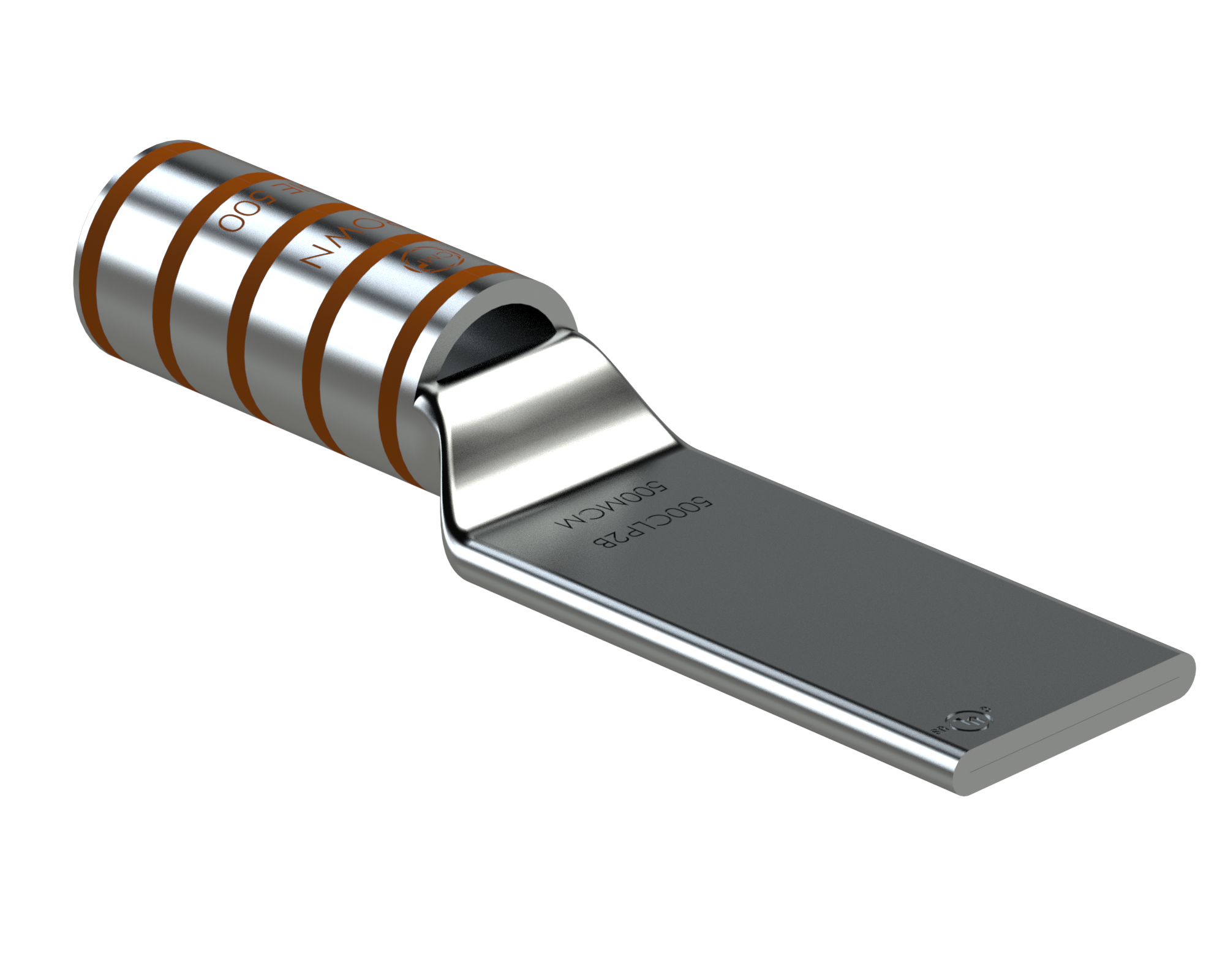

CLP2B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLP2BW. Long, blank palms enable custom stud hole drilling on installation, to suit connection requirements.

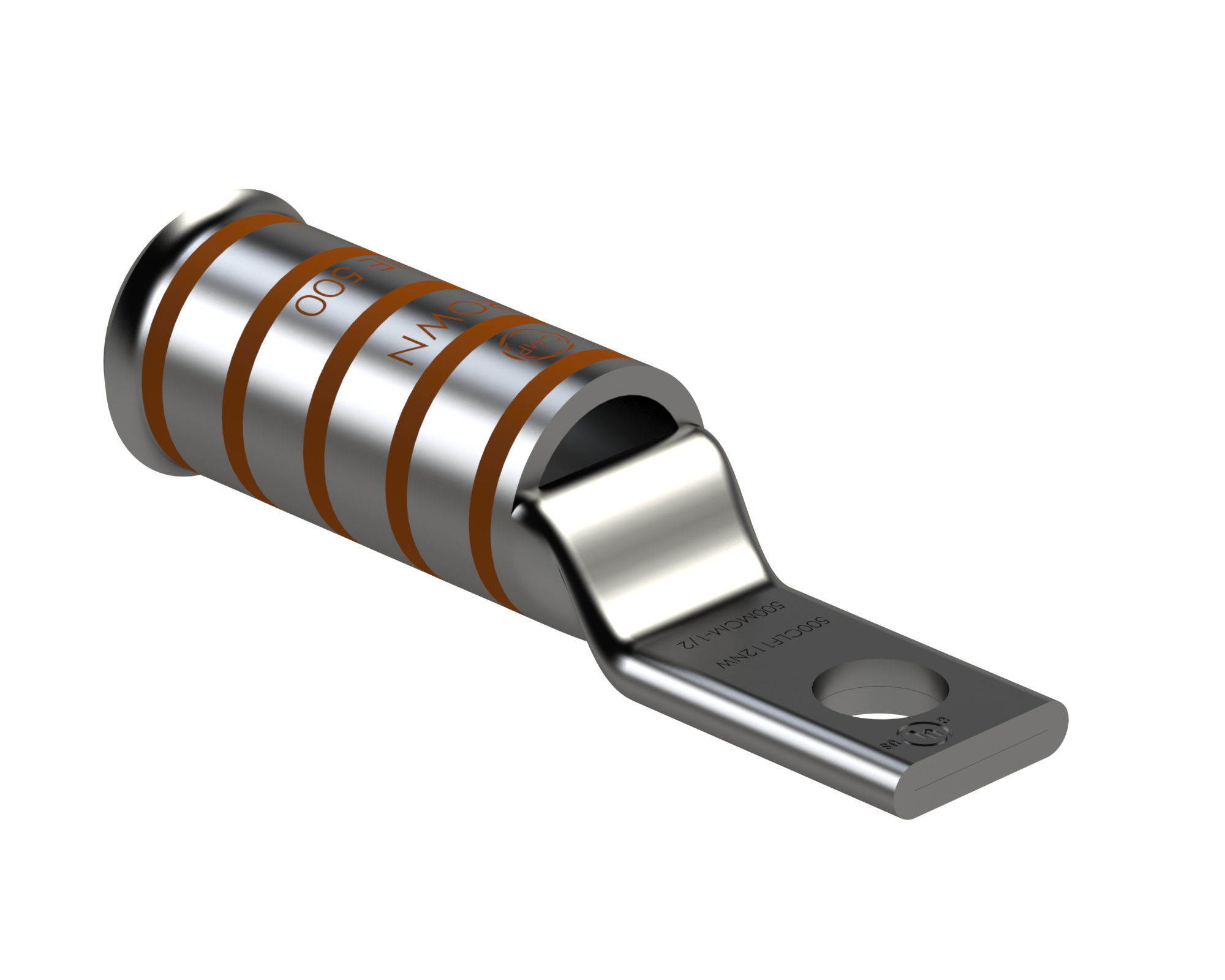

CLP1B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLP1BW. Blank palms enable custom stud hole drilling on installation, to suit connection requirements.

CHLP1 | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CSHD | Metric Cable Splice Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

CSSDF | Metric Cable Splice Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class B, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

CSDF2 | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class B, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is an inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CSDF212X. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

CHLF1 | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

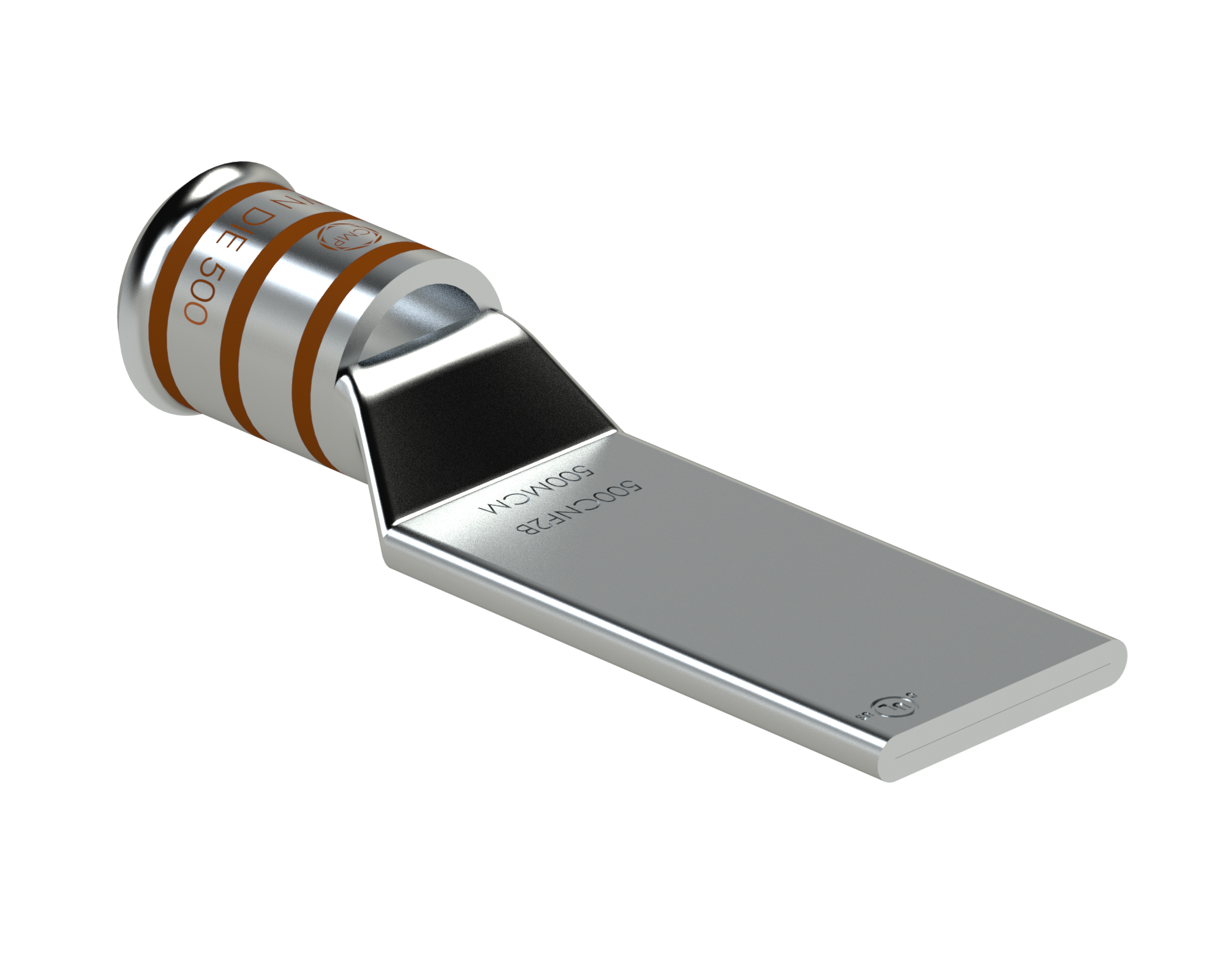

CNF2B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Long, blank palms enable custom stud hole drilling on installation, to suit connection requirements.

CHLP2 | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CHLF2 | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CSHDF | Metric Cable Splice Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

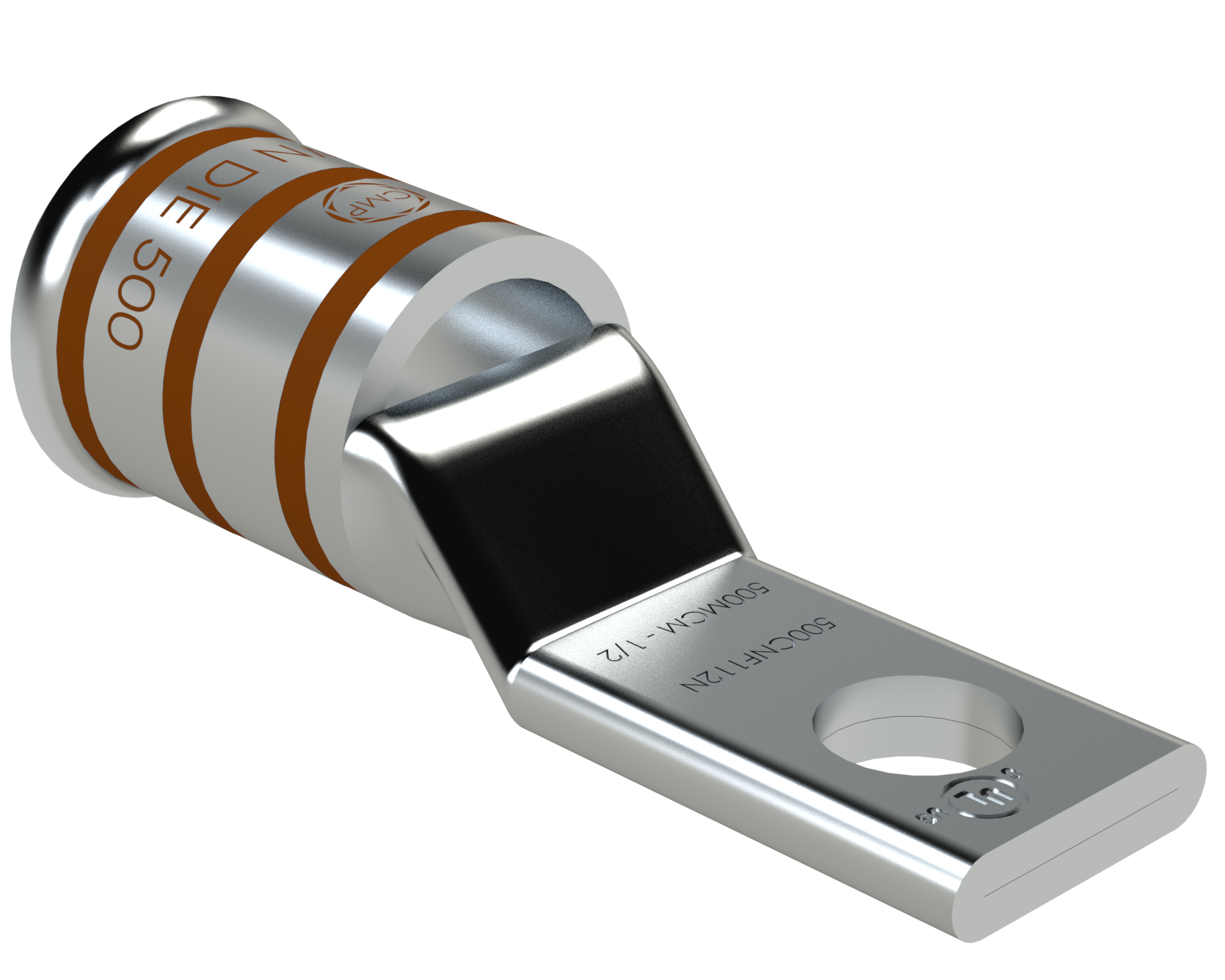

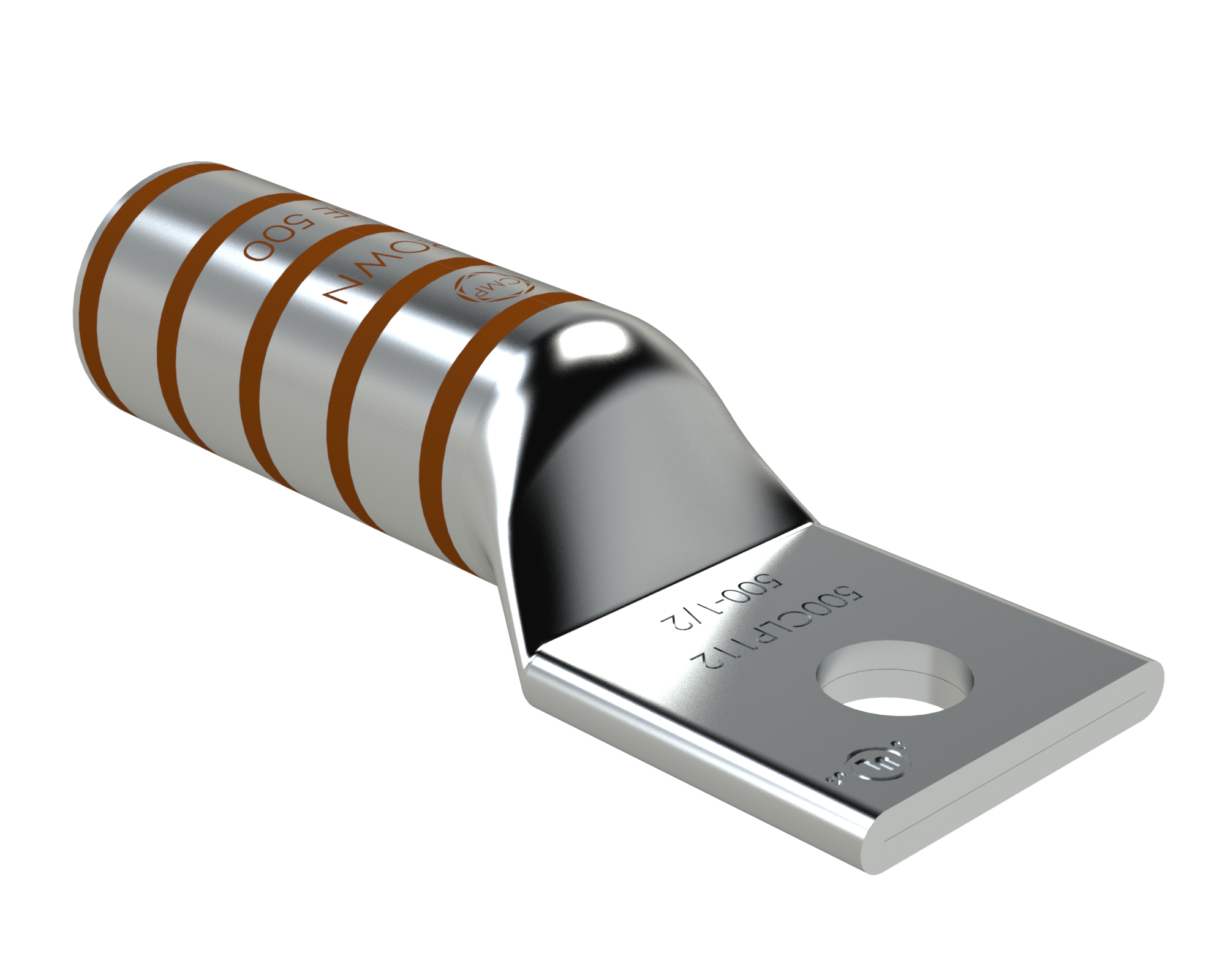

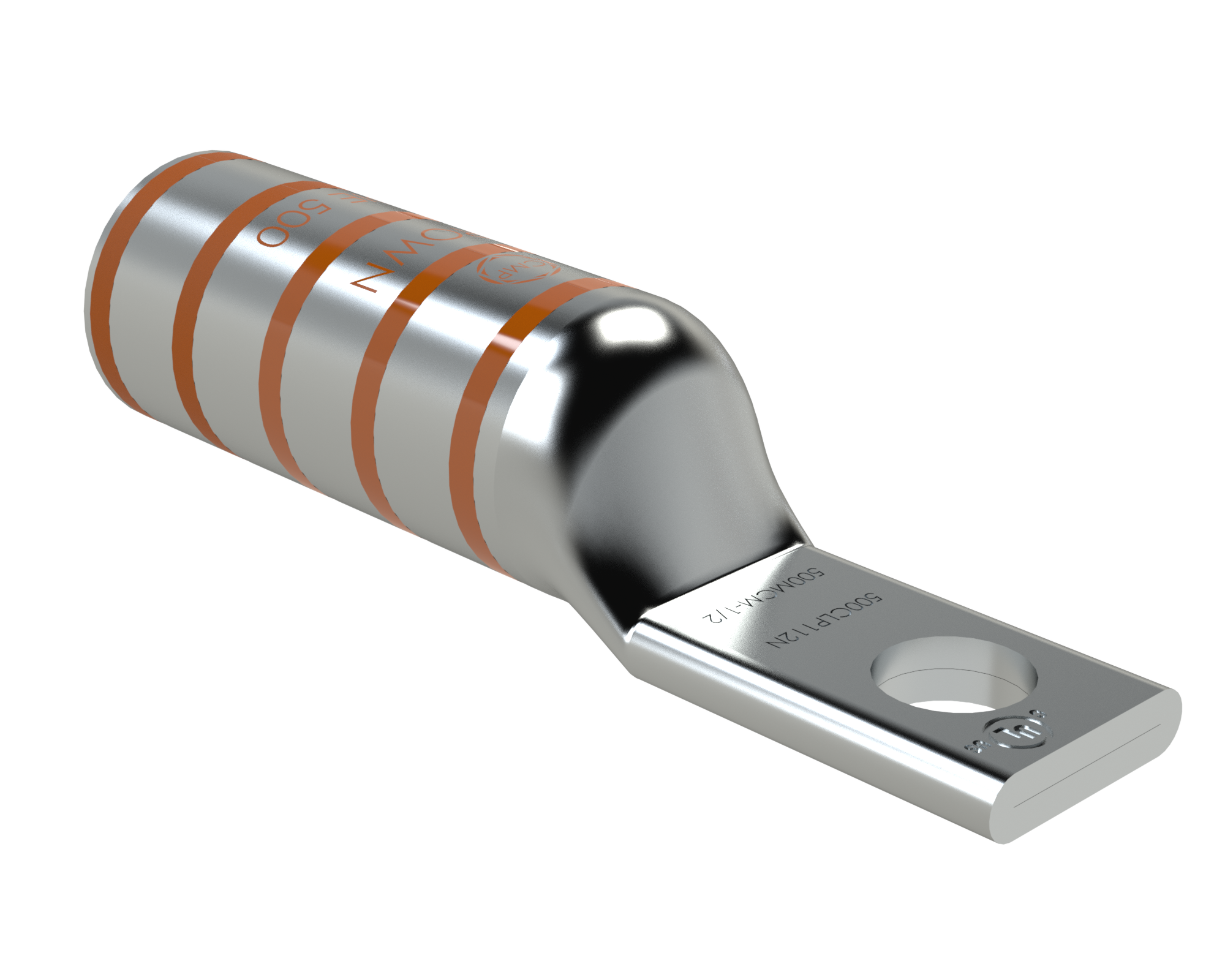

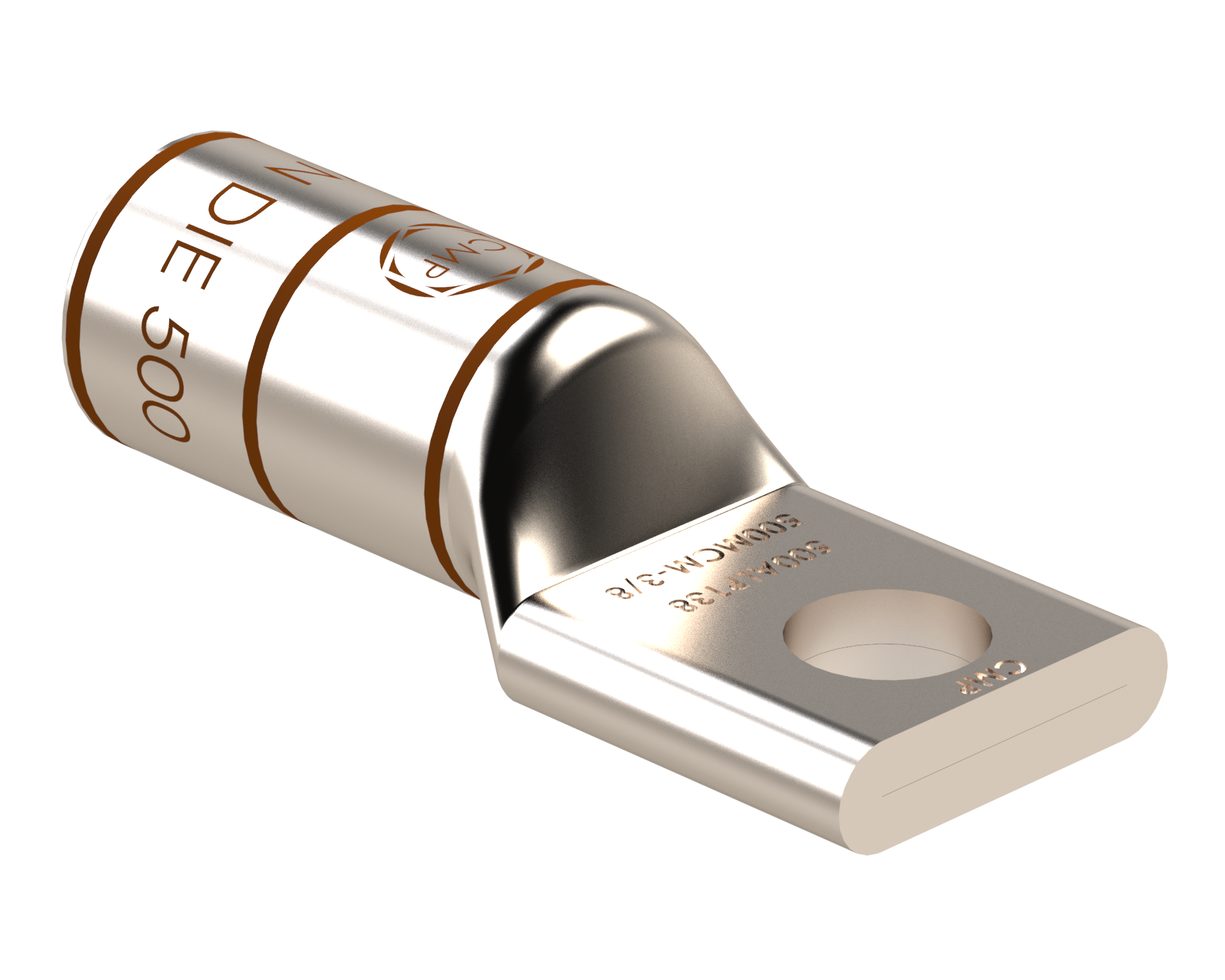

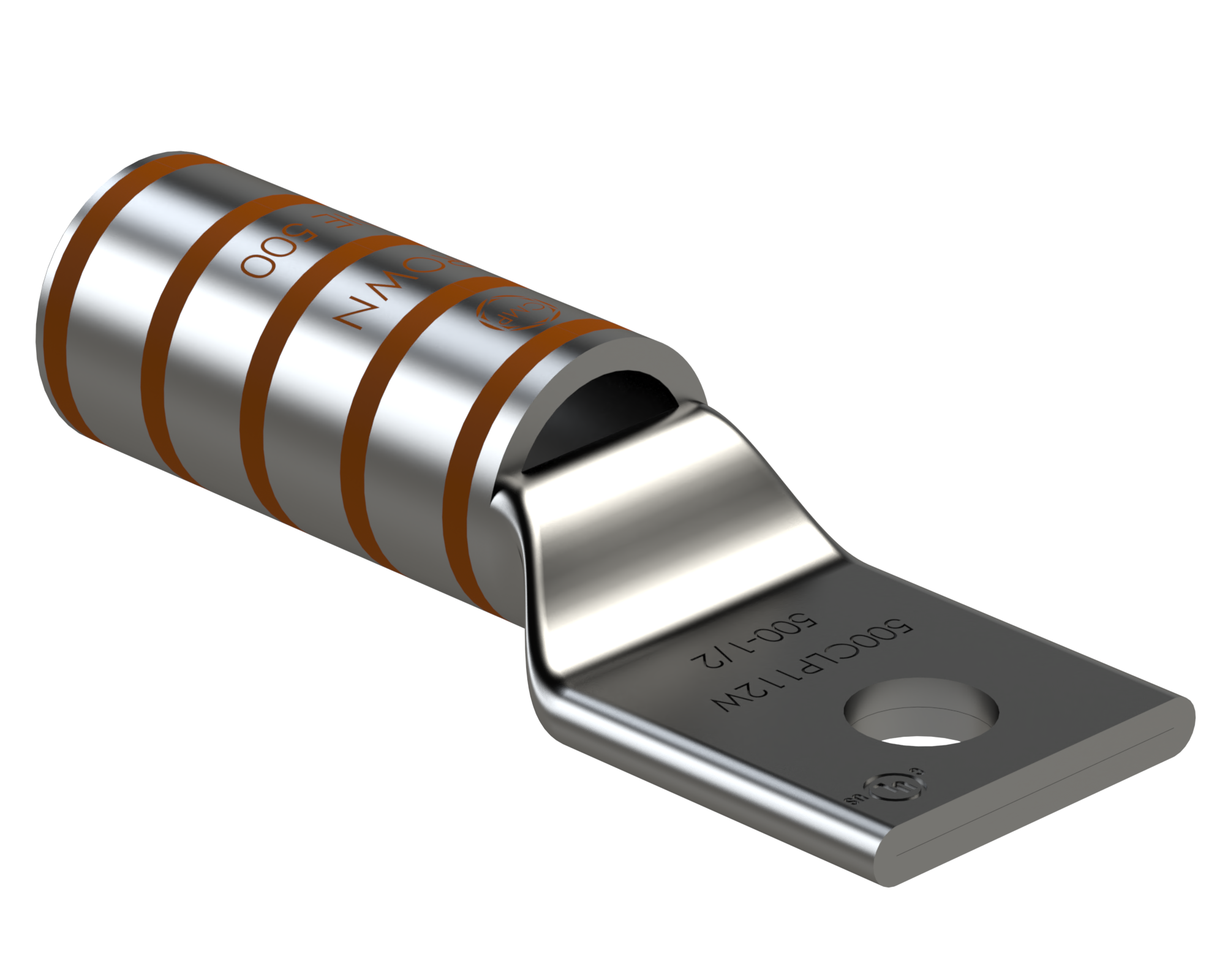

CNP1 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNF1 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNF2 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

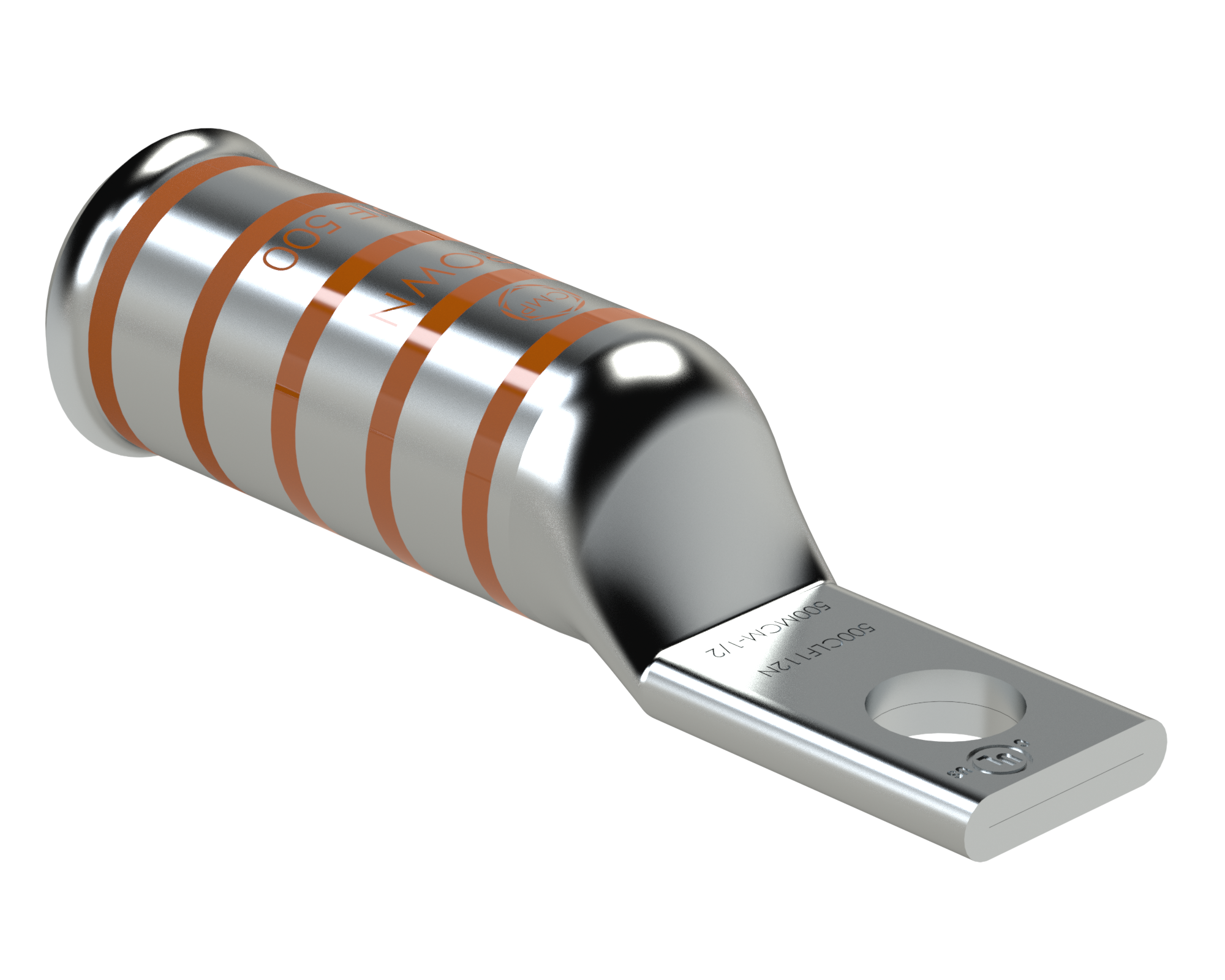

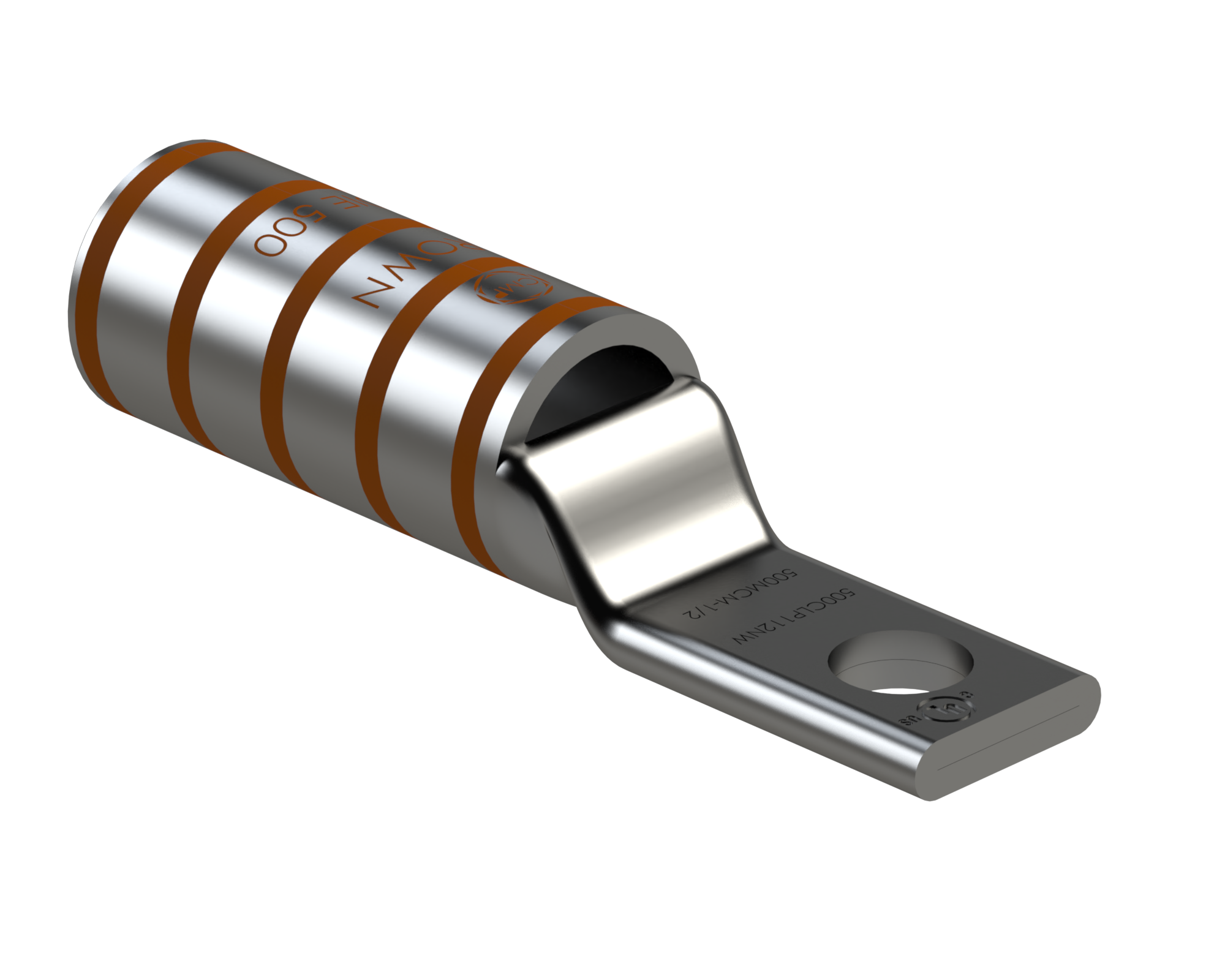

CLP1 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLP1-W. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

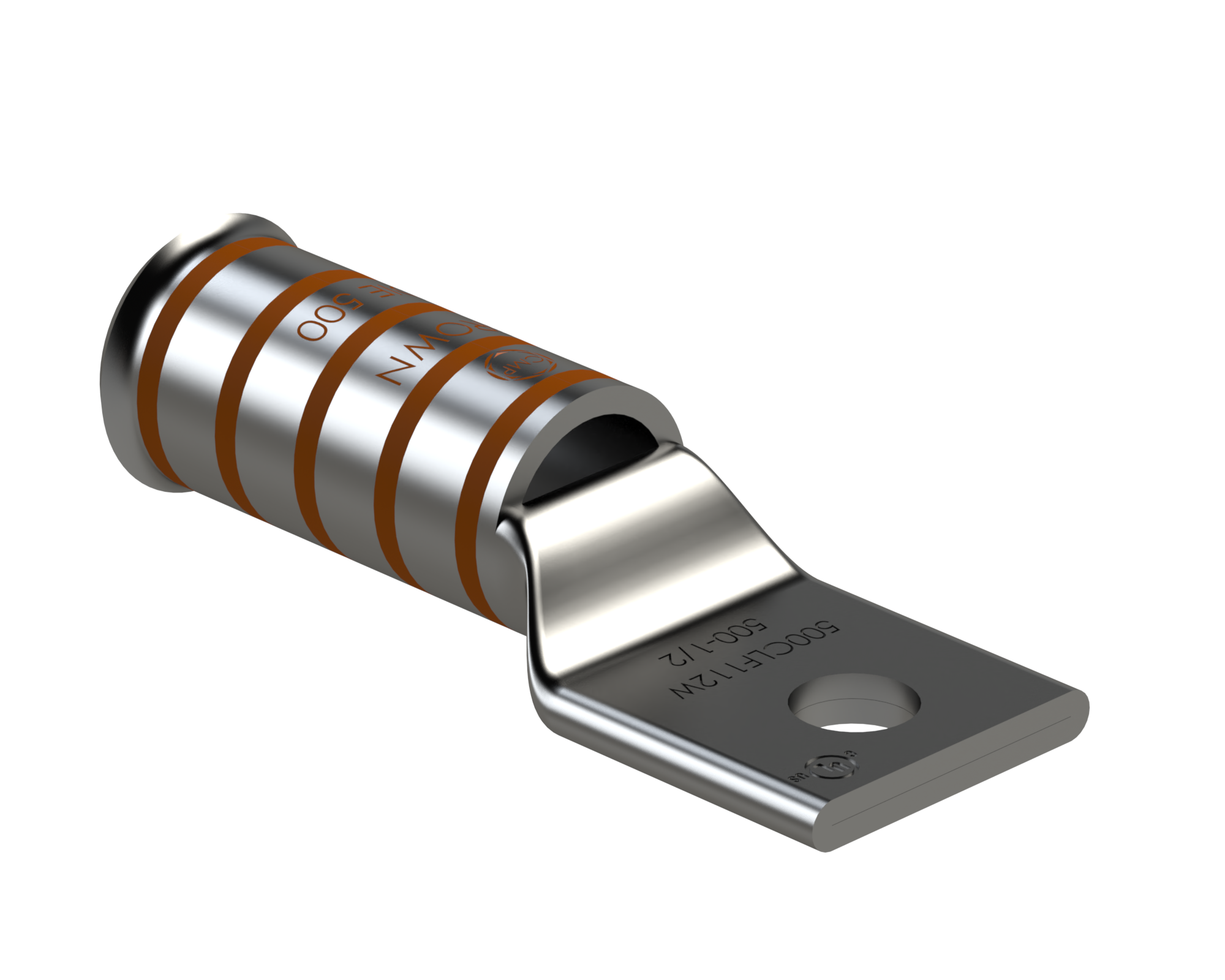

CLF1 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLF1-W. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

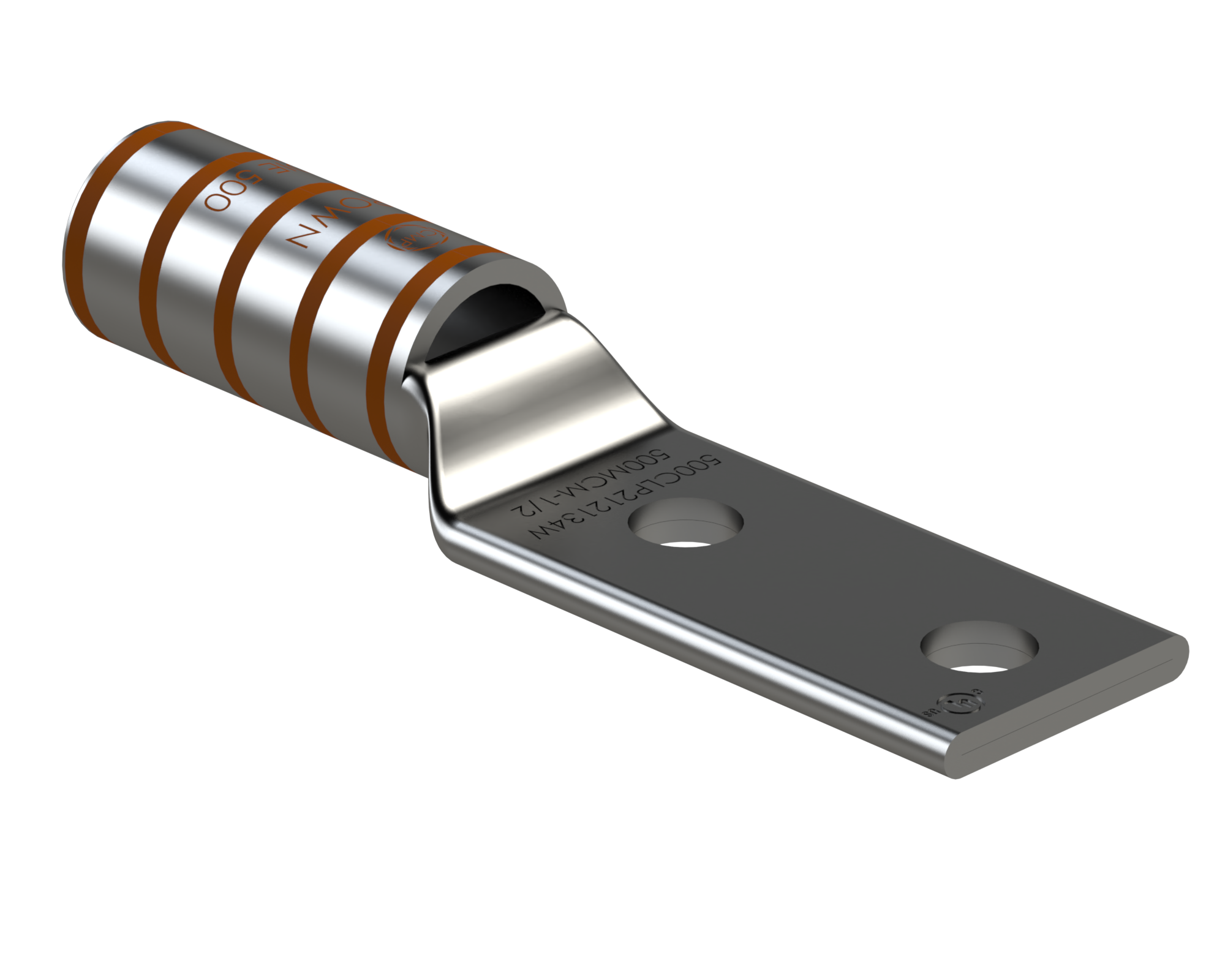

CLP2 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLP2-W. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

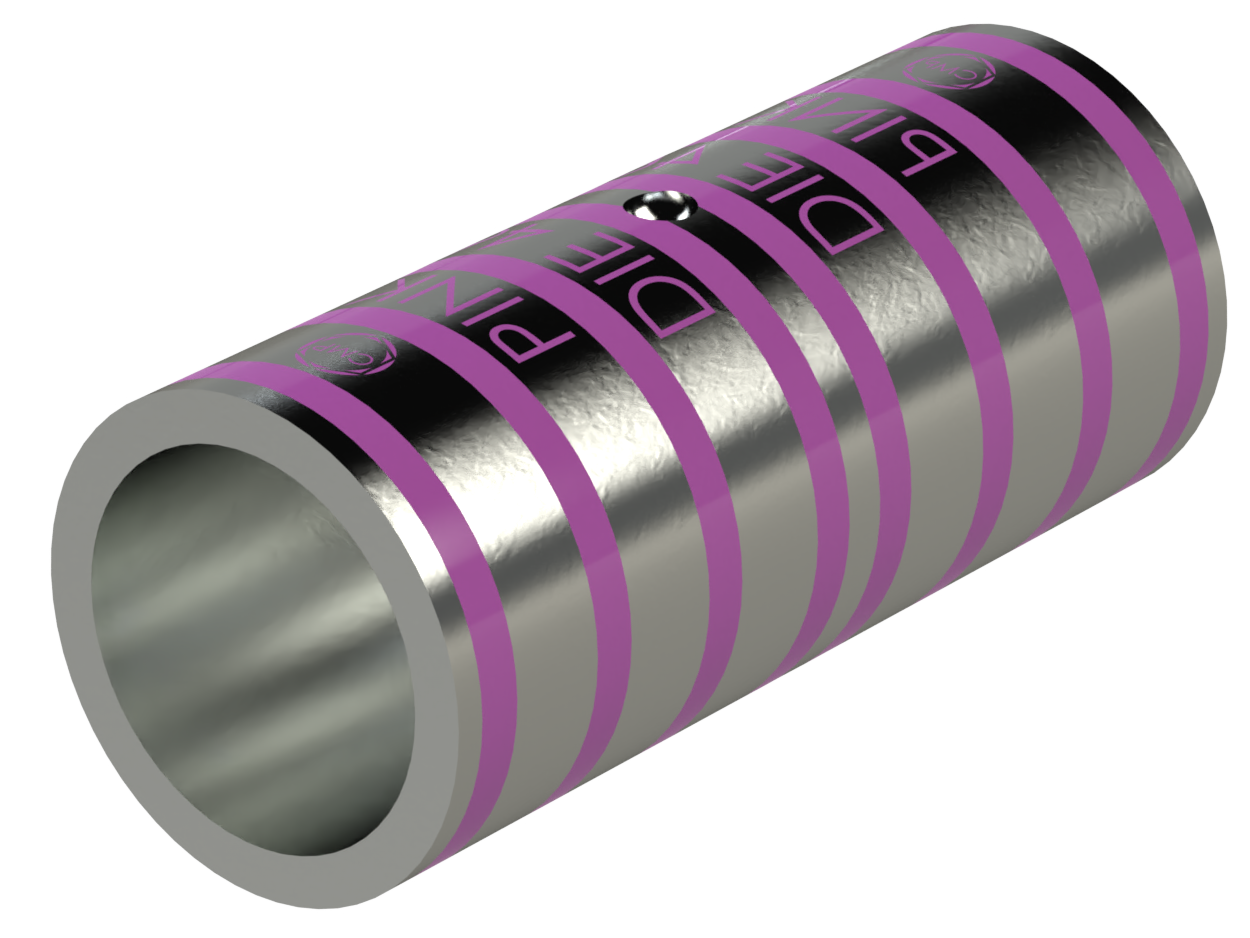

CSF | Cable Splice (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

CNF1B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Blank palms enable custom stud hole drilling on installation, to suit connection requirements.

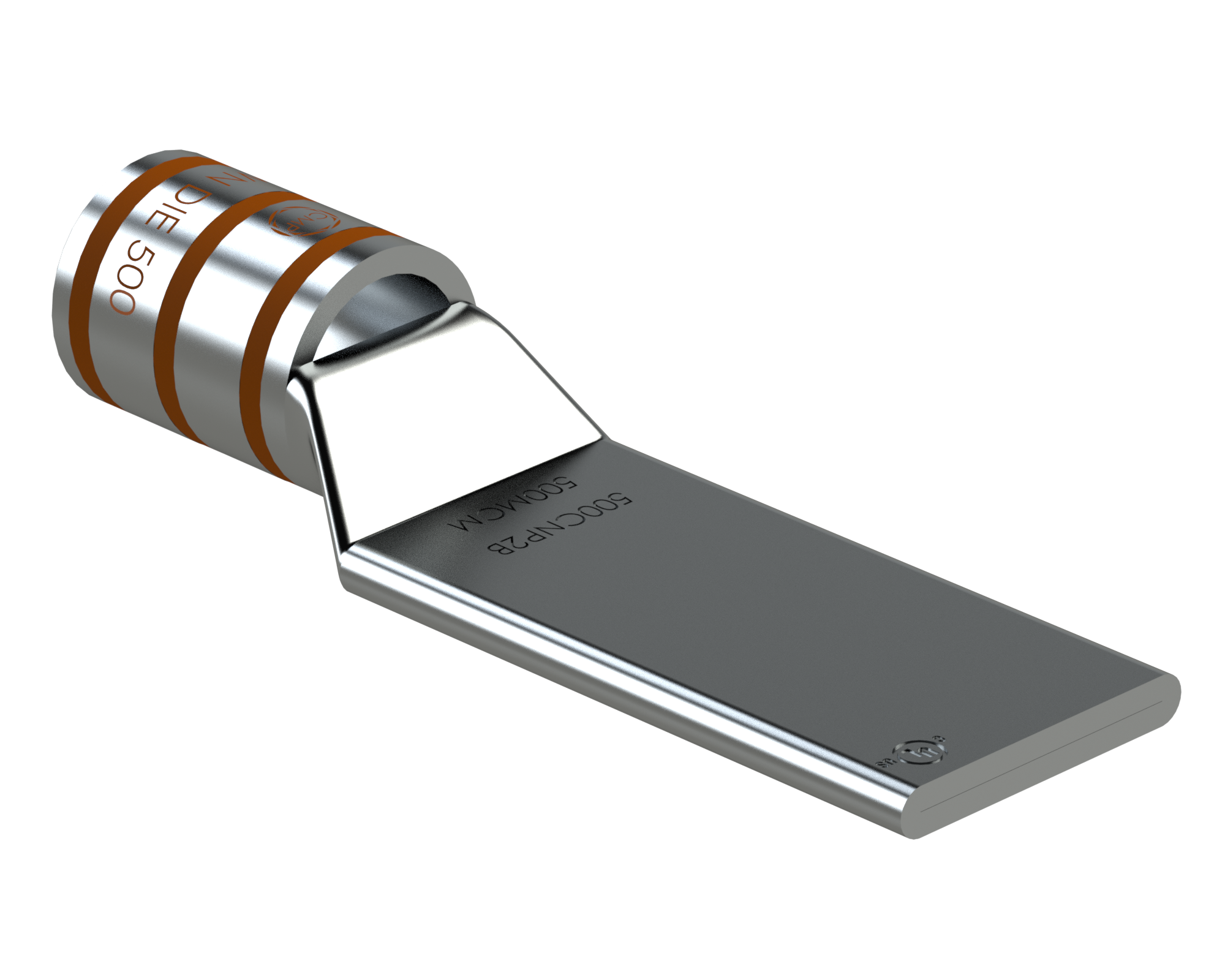

CNP2B | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion. Long, blank palms enable custom stud hole drilling on installation, to suit connection requirements.

CLP1-N | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor applications; inspection window can be added as an option - see data sheet CLP1-NW. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CNP2-45N | Imperial Cable Lug Cable Lug

These products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a standard large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option - contact CMP for more information. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNP2-90N | Imperial Cable Lug Cable Lug

These products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CNF2-90N | Imperial Cable Lug Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Angled palm to ensure connection can be made with minimal bending of cables. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

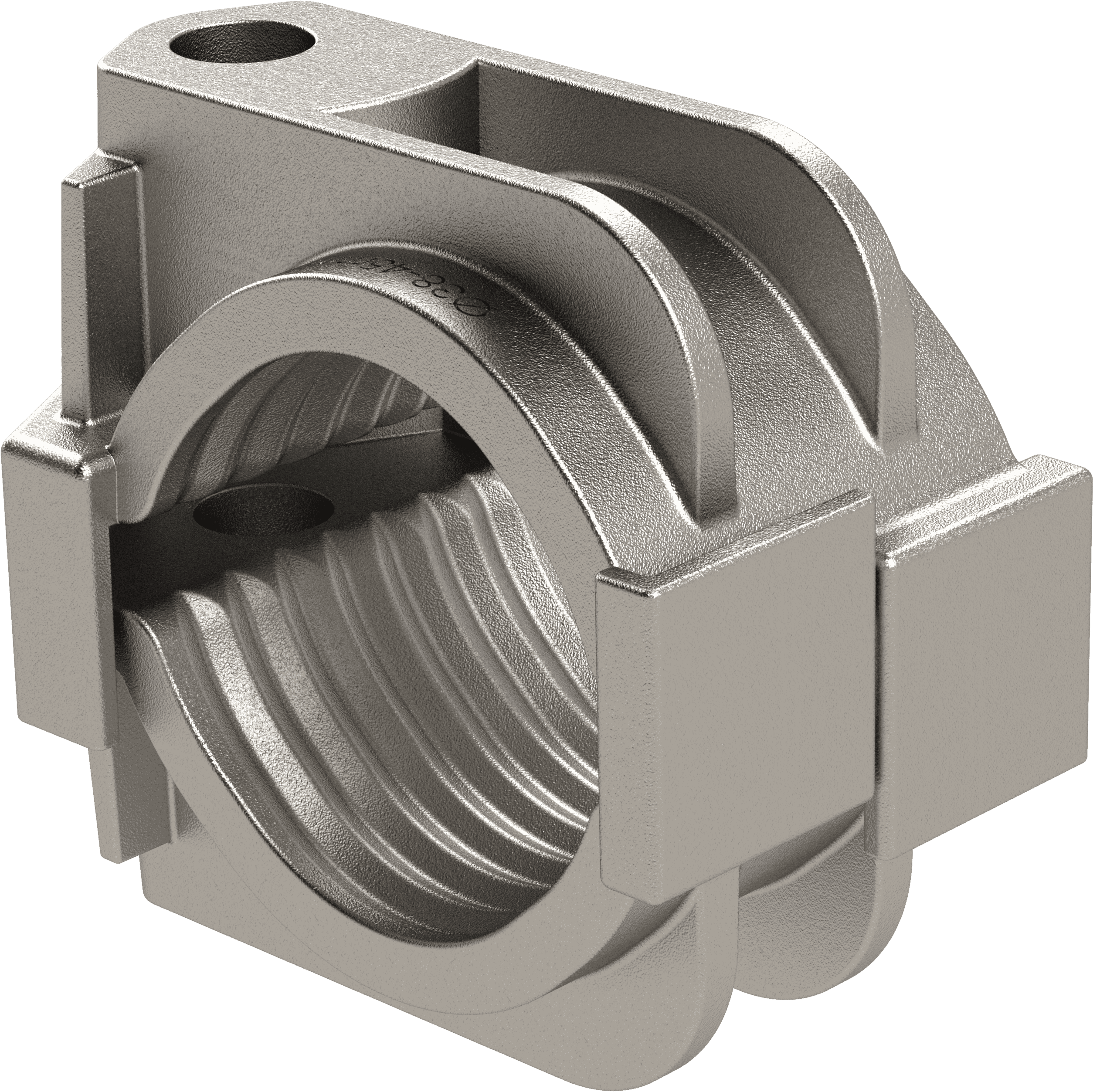

BH | Metric Cable Lug

CMP 12 ton Hexagonal Compression Dies are specifically designed to provide superior electrical and mechanical properties of the crimped product. The hexagonal compression aperture is designed for the most optimal compression ratio of copper compression lugs and splices. These dies suit copper compression lugs and splices from 10 mm² to 400 mm². CMP dies are certified with CMP Connect lugs and splices; they are manufactured from high strength tool steel, ensuring long life and wear resistance. All dies have a black oxide coating, providing a hard wearing corrosion resistance. Clear marking on the front faces makes die selection for the CMP Connect range easy. There is an identification imprint on the internal crimping aperture, which stamps the die index number onto the crimped product for easy inspection.

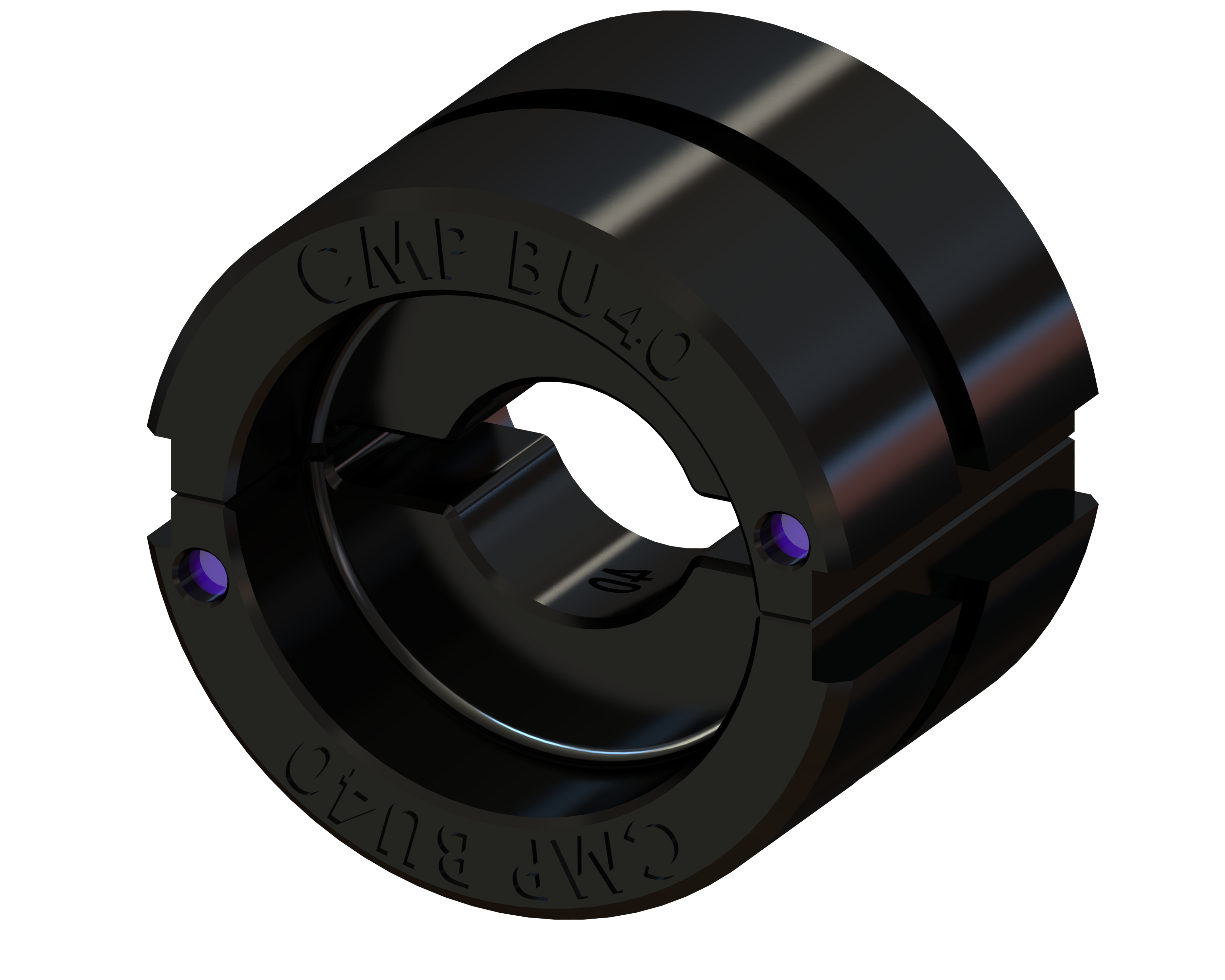

BU | Imperial Cable Lug

CMP 120kN / 12 ton ‘U’ Type Compression Dies are specifically designed to provide superior electrical and mechanical properties of the crimped product. The rounded compression aperture is designed for the most optimal compression ratio of copper compression lugs and splices. These dies suit copper compression lugs and splices from 8 AWG to 750 kcmil. CMP dies are certified with CMP Connect lugs and splices; they are manufactured from high strength tool steel, ensuring long life and wear resistance. All dies have a black oxide coating, providing a hard wearing corrosion resistance. Clear marking on the front faces makes die selection for the CMP Connect range easy. There is an identification imprint on the internal crimping aperture, which stamps the die index number onto the crimped product for easy inspection.

ALP2 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high conductivity aluminium seamless tubing, these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Aluminium lug barrels are filled with grease and capped as an extra layer of protection from oxidation. No inspection window as standard to prevent moisture ingress. The centres of the two stud holes are detailed in the dimension table. Custom stud hole dimensions are available on request.

ALP1 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high conductivity aluminium seamless tubing, these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. Aluminium lug barrels are filled with grease and capped as an extra layer of protection from oxidation. No inspection window as standard to prevent moisture ingress. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request.

CHDP1-N | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CHDP112NX. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

CHDF1-N | Metric Cable Lug Cable Lug

These flared entry products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Narrow palm cable lugs have a contained palm width to ensure a connection can be made in space constrained installations. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is a large inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CHDF112NX. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

250H | Metric Cable Lug

CMP 250kN / 25 ton Hexagonal Compression Dies are specifically designed to provide superior electrical and mechanical properties of the crimped product. The hexagonal compression aperture is designed for the most optimal compression ratio of copper compression lugs and splices. These dies suit copper compression lugs and splices from 240 mm² to 630 mm². CMP dies are certified with CMP Connect lugs and splices; they are manufactured from high strength tool steel, ensuring long life and wear resistance. All dies have a black oxide coating, providing a hard wearing corrosion resistance. Clear marking on the front faces makes die selection for the CMP Connect range easy. There is an identification imprint on the internal crimping aperture, which stamps the die index number onto the crimped product for easy inspection.

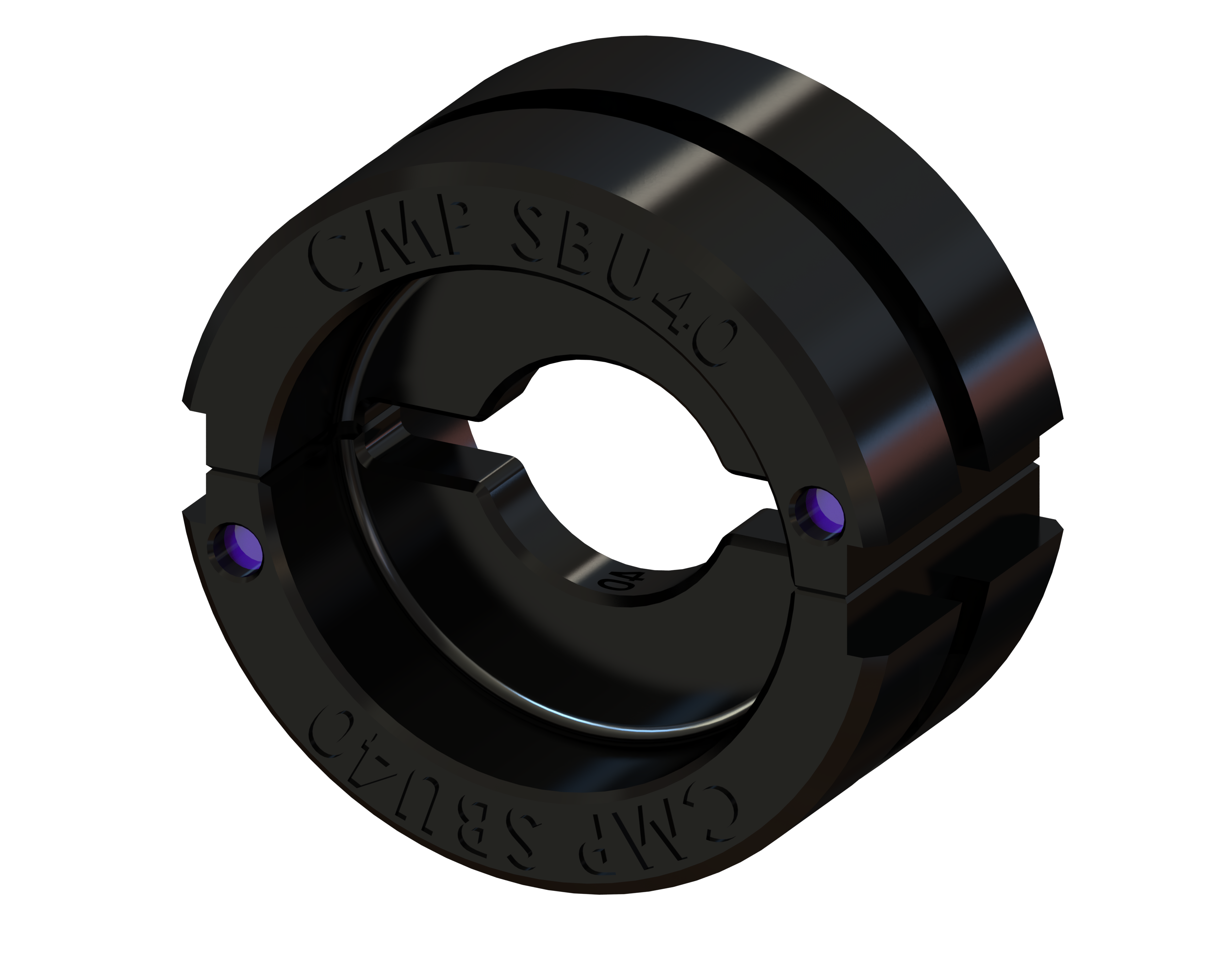

SBU | Imperial Cable Lug

CMP 6 ton ‘U’ Type Compression Dies are specifically designed to provide superior electrical and mechanical properties of the crimped product. The rounded compression aperture is designed for the most optimal compression ratio of copper compression lugs and splices. These dies suit copper compression lugs and splices from 8 AWG to 600 kcmil. CMP dies are certified with CMP Connect lugs and splices; they are manufactured from high strength tool steel, ensuring long life and wear resistance. All dies have a black oxide coating, providing a hard wearing corrosion resistance. Clear marking on the front faces makes die selection for the CMP Connect range easy. There is an identification imprint on the internal crimping aperture, which stamps the die index number onto the crimped product for easy inspection.

SBH | Metric Cable Lug

CMP 6 ton Hexagonal Compression Dies are specifically designed to provide superior electrical and mechanical properties of the crimped product. The hexagonal compression aperture is designed for the most optimal compression ratio of copper compression lugs and splices. These dies suit copper compression lugs and splices from 6 mm² to 300 mm². CMP dies are certified with CMP Connect lugs and splices; they are manufactured from high strength tool steel, ensuring long life and wear resistance. All dies have a black oxide coating, providing a hard wearing corrosion resistance. Clear marking on the front faces makes die selection for the CMP Connect range easy. There is an identification imprint on the internal crimping aperture, which stamps the die index number onto the crimped product for easy inspection.

450H | Metric Cable Lug

CMP 45 ton Hexagonal Compression Dies are specifically designed to provide superior electrical and mechanical properties of the crimped product. The hexagonal compression aperture is designed for the most optimal compression ratio of copper compression lugs and splices. These dies suit copper compression lugs and splices from 300 mm² to 1,000 mm². CMP dies are certified with CMP Connect lugs and splices; they are manufactured from high strength tool steel, ensuring long life and wear resistance. All dies have a black oxide coating, providing a hard wearing corrosion resistance. Clear marking on the front faces makes die selection for the CMP Connect range easy. There is an identification imprint on the internal crimping aperture, which stamps the die index number onto the crimped product for easy inspection.

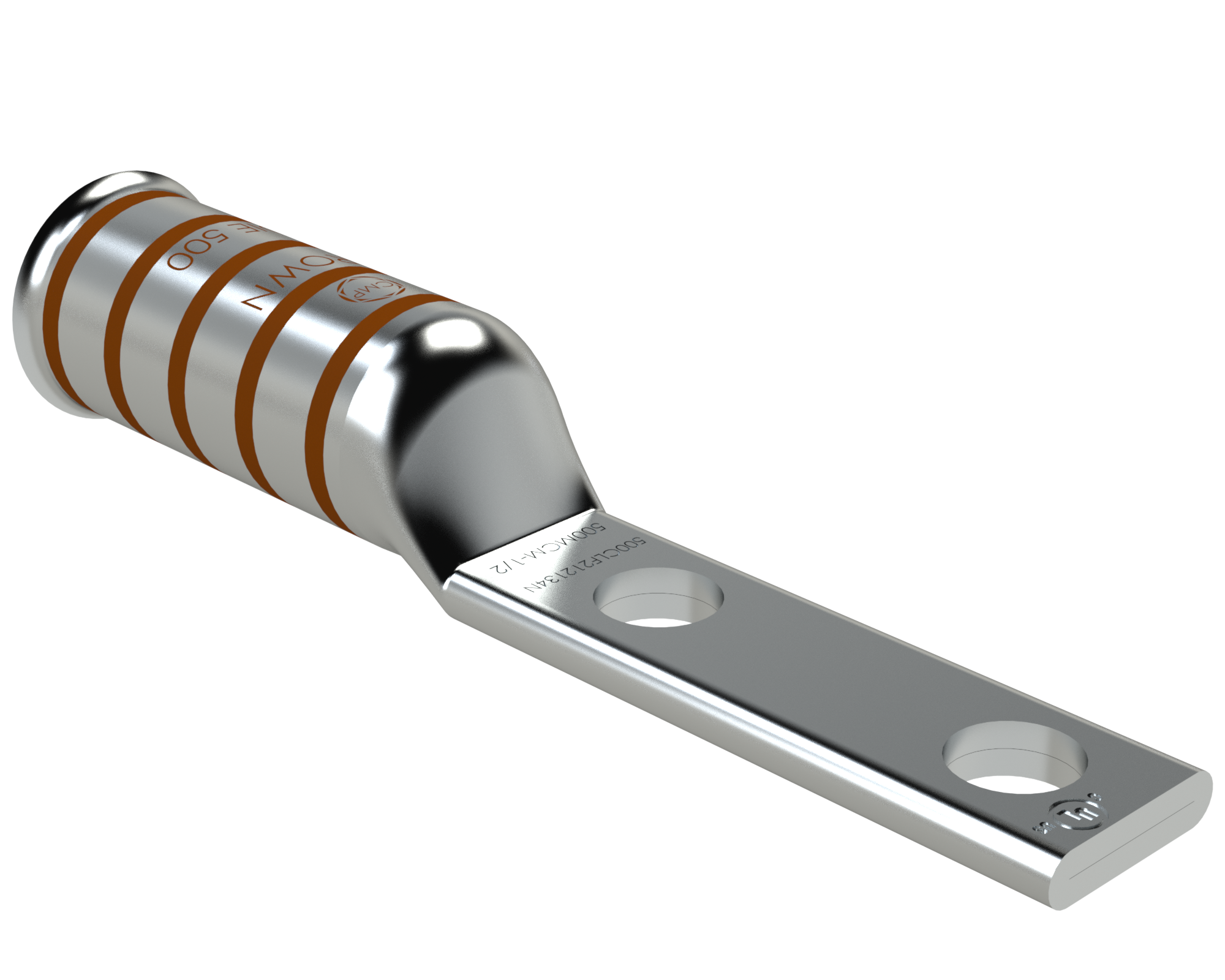

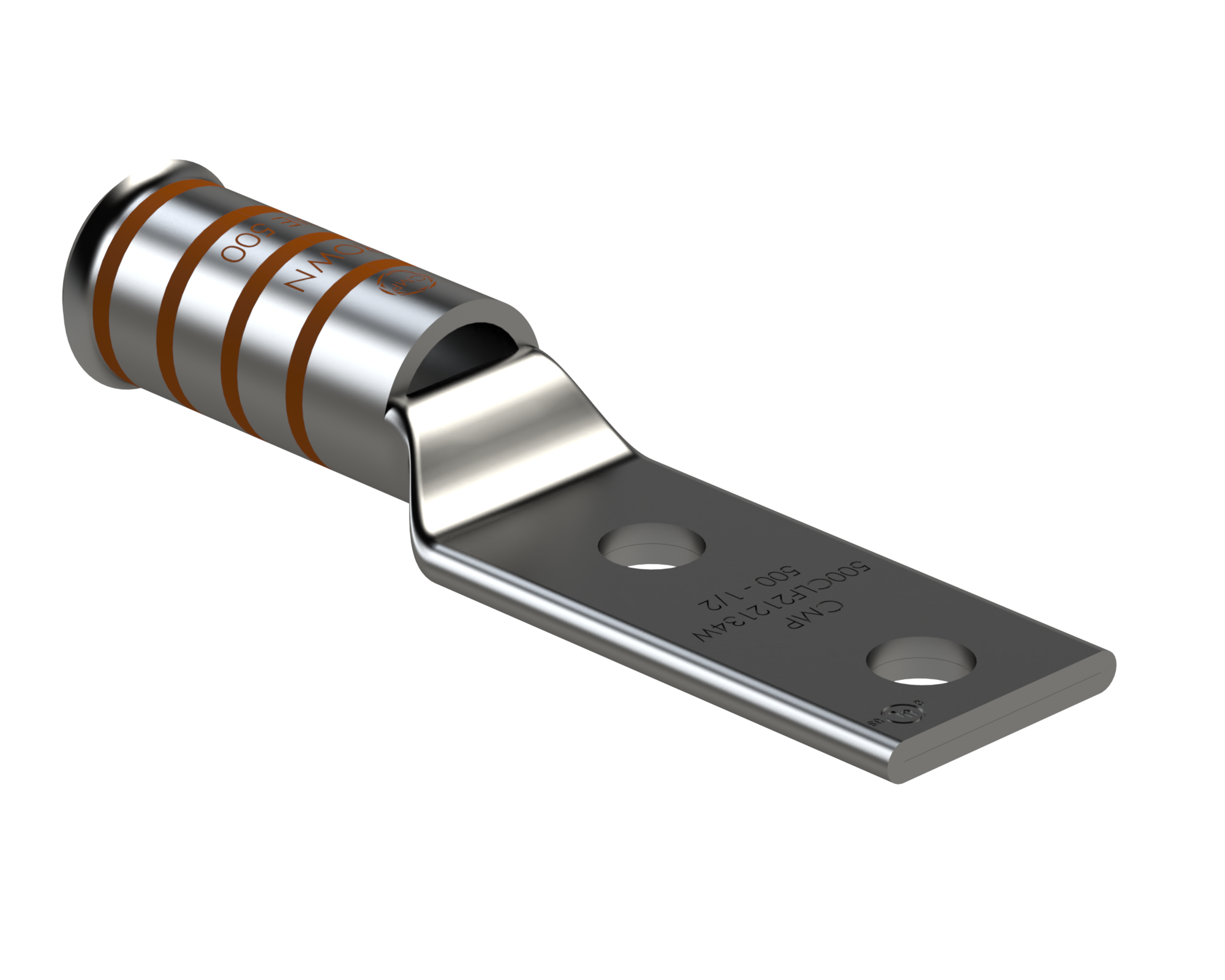

CLF2 | Cable Lug (AWG / MCM / kcmil) Cable Lug

These flared entry products have been designed and third party certified to UL 486A-486B and CSA C22.2 No. 65, for high quality and reliable crimping. Long barrel compression cable lugs enable additional crimps, offering increased electrical and mechanical properties. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for MV and outdoor application; inspection window can be added as an option - see data sheet CLF2-W. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

CMP-HZ400 | Manual Hydraulic Crimping Tool Tools

This versatile manual hydraulic crimping tool is designed for crimping cable lugs ranging from 10mm² to 400mm² (#8AWG to 750kcmil) and is compatible with CMP BH & BU crimping dies. It features 360° head rotation for easy manoeuvrability and a double-speed action for fast die advancement towards during operation. A built-in safety valve ensures user safety by bypassing the oil supply when maximum pressure is reached. Available with full CMP die sets on request—contact CMP Products for more information.

CMP-BPL062 | Battery-Operated Crimping Tool Tools

This lightweight hydraulic battery-operated crimping tool is perfect for crimping cable lugs ranging from 6mm² to 300mm² (#8AWG to 650kcmil) and is compatible with CMP SBH & SBU crimping dies. Powered by DeWalt 18V Li-Ion batteries, it features 180° head rotation for easy handling and separate advance and release triggers for smooth operation. Its robust plastic housing has a non-slip coating, while an LED panel displays battery charge, cycle compliance, and maintenance alerts. Additional features include a handling ring for a carrying strap or safety cable, built-in LED lighting for better visibility. Additionally, it has a USB connection for dedicated software, enabling analysis and preventative maintenance. Full CMP die sets are available upon request; contact CMP Products for details.

E1FW | E Series Cable Gland

The E1FW range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a seal on both the inner and the outer sheath.

E1FWEVO | E Series Cable Gland

The E1FW EVO range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a seal on both the inner and the outer sheath.

CSDP1 | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class B, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is an inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CSDP112X. Standard stud hole sizes are detailed in the dimension table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

CSDP2 | Metric Cable Lug Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class B, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. There is an inspection window to visually inspect conductor insertion; the inspection window can be removed as an option by adding suffix "X" - Example: 300CSDP212X. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request. Blank palms available on request; please contact CMP for more information.

CSSDP | Metric Cable Splice Cable Lug

These products have been designed and third party certified to IEC 61238-1 Class B, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these splice connectors are precisely dimensioned to achieve optimal crimping with suitable conductors. The splice connectors are annealed to enhance durability, minimising risk of fracture. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection.

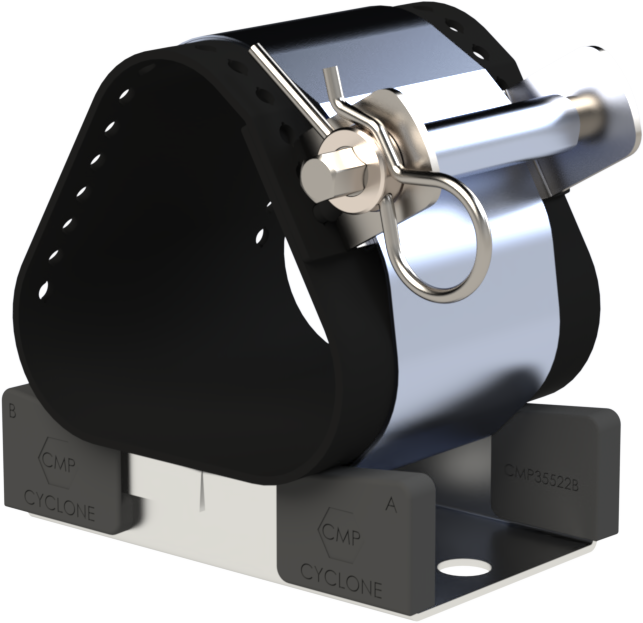

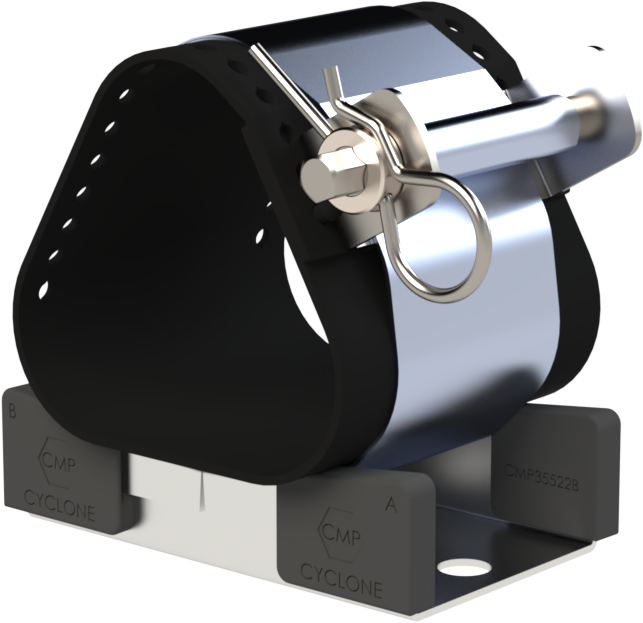

3STR | Cyclone 3 IR Cable Cleat

The CMP Cyclone Strap (3STR) is a single/parallel/trefoil/quad composite intermediate restraint, designed and tested in accordance with IEC 61914. Manufactured from 316L Stainless Steel with Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric liners to protect the cable sheath. Intermediate restraints are cable retaining devices that can be used in conjunction with fixed cable cleats; they hold the cables together in formation, in order to provide resistance to electromechanical forces. Using intermediate restraints between each cable cleat reduces installation time and cost when compared to alternative cleat only systems for use in trefoil or quad formations. CMP has tested the Cyclone intermediate strap range in accordance to IEC 61914 and is certified to offer these for use with any CMP trefoil cable cleats at suitable peak fault levels.

QHDSS | Mercury Cable Cleat

The CMP Mercury is a quad composite cable cleat, designed and tested in accordance with IEC 61914. Manufactured from 316L Stainless Steel with Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric liners to protect the cable sheath. The cleat is designed to accept four cables of the same size, for example three phase power cables plus a neutral cable. The cable cleat has been designed and tested for high short circuit fault withstand on cables held in quad formation, to ensure the securing and retention of cables without cable damage. The two M10 and one M12 fixing clearance holes in the base allows versatility of fixing the cleat to the mounting structure.

A2 | SSUA Cable Gland

The A2 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a single seal on the cable outer sheath.

A2E100 | SSUA Cable Gland

The A2e100 range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed to comply 100% with the requirements of IEC 60079-0. For use in Ex applications where external clamping of the cable is not practical or desireable.

A2-FL | SSUA Cable Gland

The A2-FL range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for cables with pre-installed lugs, allowing the lug to be passed through the gland without any disassembly.

A2EC-FL | SSUA Cable Gland

The A2EC-FL range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for cables with pre-installed lugs, allowing the lug to be passed through the gland without any disassembly. Includes an external integral cable clamp.

A2F | SSUA Cable Gland

The A2F range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

A2F100 | SSUA Cable Gland

The A2F100 range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed to comply 100% with the requirements of IEC 60079-0. For use in Ex applications where external clamping of the cable is not practical or desireable.

A2F100HC | SSUA Cable Gland

The A2F100HC range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to provide superior cable retention and strain relief, this range includes a hose connection for cable housed in protective hose.

A2FF | SSUA Cable Gland

The A2-FF range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for flat form / heat trace applications.

A2FFC | CC Cable Gland

The A2FFC range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

A2FFF | SSUA Cable Gland

The A2F-FF range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

A2FHT | SSUA Cable Gland

The A2FHT range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed for high temperature applications.

A2FRC | CC Cable Gland

The A2FRC range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

A2HT | SSUA Cable Gland

The A2HT range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for high temperature applications.

A2RC | CC Cable Gland

The A2RC range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a single seal on the cable outer sheath.

A2SOLO | SSUA Cable Gland

The A2 SOLO range of LSF cable cable gland kits are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for low smoke and fume applications. LUL (London Underground) Approved.

B323 | SSI Cable Gland

The B323 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents. Includes external high current capacity earth connection.

B324 | SSI Cable Gland

The B324 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents. Includes external high current capacity earth connection.

B327 | SSI Cable Gland

The B327 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents. Includes external high current capacity earth connection.

B347 | SSI Cable Gland

The B347 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents.

B348 | SSI Cable Gland

The B348 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents.

B350 | SSI Cable Gland

The B350 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents.

B367 | SSI Cable Gland

The B367 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents. Includes external high current capacity earth connection.

B368 | SSI Cable Gland

The B368 range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed to be insulated from the equipment to enable zoning of earthed neutral systems and eliminate circulating currents.

BW | NSA Cable Gland

The BW range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed generally for indoor areas as no sealing protection is provided for the cable.

BWL | NSA Cable Gland

The BWL range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed generally for indoor areas as no sealing protection is provided for the cable.

BWLCIEL | NSA Cable Gland

The BW CIEL range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with an external high current capacity earth connection.

BWSOLO | NSA Cable Gland

The BW SOLO range of LSF cable cable gland kits are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for low smoke and fume applications. LUL (London Underground) Approved.

C2K | SSA Cable Gland

The C2K range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath and an integral protected deluge seal.

C2KGP | SSA Cable Gland

The C2KGP range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a single seal on the cable outer sheath and an integral protected deluge seal.

C2KHT | SSA Cable Gland

The C2KHT range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed for high temperature applications with a single seal on the cable outer sheath and an integral protected deluge seal.

C2KX | SSA Cable Gland

The C2KX range of cable glands are for use in heavy duty applications in Hazardous (Classified) Locations. Designed with a single seal on the cable outer sheath and an integral protected deluge seal.

CW | SSA Cable Gland

The CW range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a single seal on the cable outer sheath.

CWCIEL | SSA Cable Gland

The CW CIEL range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with an external high current capacity earth connection.

CWE | SSA Cable Gland

The CWe range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

CWHT | SSA Cable Gland

The CWHT range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for high temperature applications.

CWSOLO | SSA Cable Gland

The E1W SOLO range of LSF cable cable gland kits are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for low smoke and fume applications. LUL (London Underground) Approved.

CX | SSA Cable Gland

The CX range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a single seal on the cable outer sheath.

CXE | SSA Cable Gland

The CXe range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a single seal on the cable outer sheath.

CXHT | SSA Cable Gland

The CXHT range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for high temperature applications.

CXT | SSUA Cable Gland

The CXT range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a single seal on the cable outer sheath.

E1FU | E Series Cable Gland

The E1FU range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a seal on both the inner and the outer sheath.

E1FX | E Series Cable Gland

The E1FX range of cable glands are for use in heavy duty applications in Explosive Atmospheres. Designed with a seal on both the inner and the outer sheath.

E1U | E Series Cable Gland

The E1U range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a seal on both the inner and the outer sheath.

E1UHT | E Series Cable Gland

The E1UHT range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for high temperature applications.

E1W | E Series Cable Gland

The E1W range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). For all types of Steel and Aluminium Wire Armoured cables. Designed with a seal on both the inner and the outer sheath.

E1WCIEL | E Series Cable Gland

The E1W CIEL range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with an external high current capacity earth connection.

E1WSOLO | E Series Cable Gland

The E1W SOLO range of LSF cable cable gland kits are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed for low smoke and fume applications. LUL (London Underground) Approved.

E1X | E Series Cable Gland

The E1X range of cable glands are for use in heavy duty applications in Industrial Areas (Safe Areas). Designed with a seal on both the inner and the outer sheath.

E2FU | E Series Cable Gland