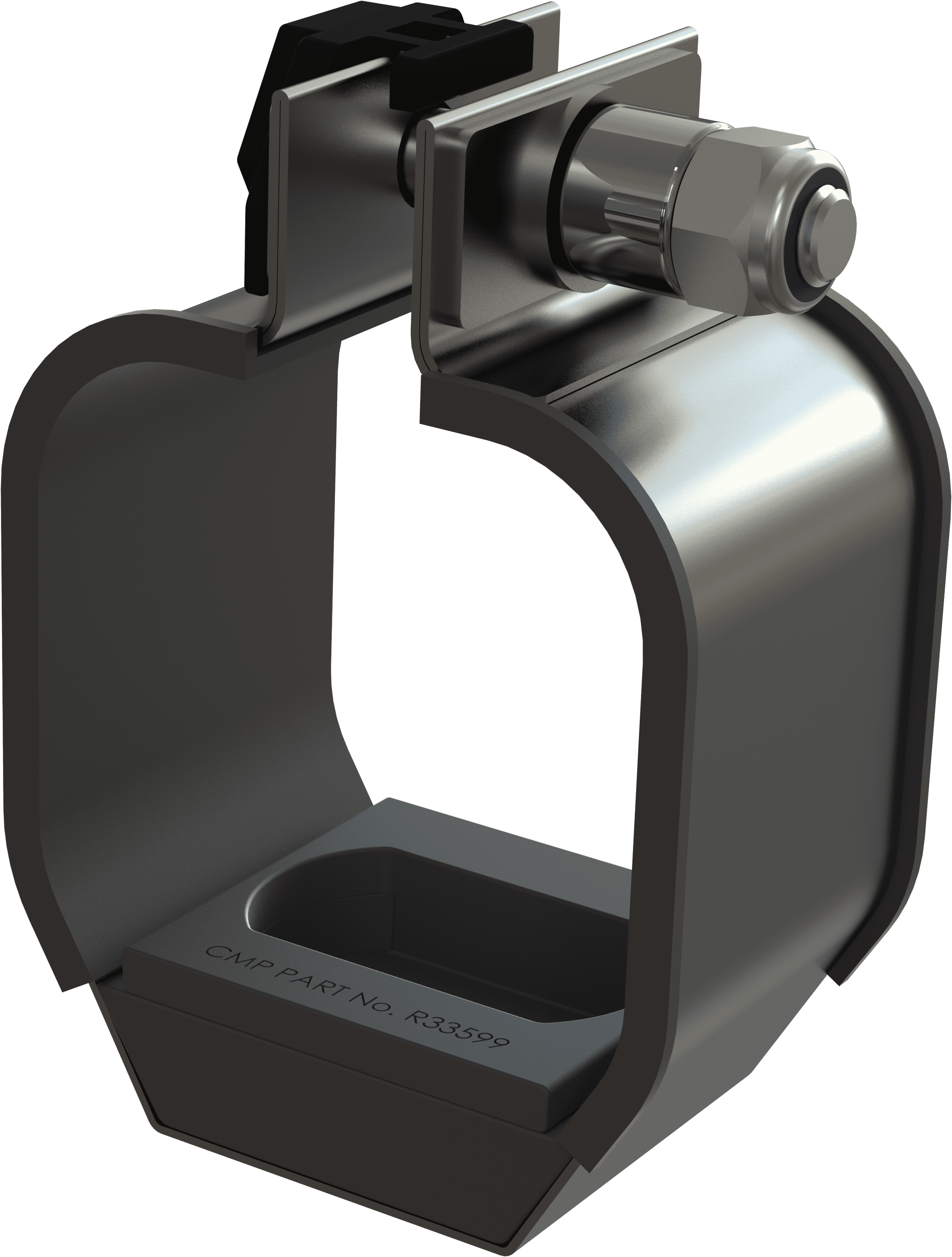

QSDSS-HT Cable Cleat

ETIM Classification

EC004588

High temperature, top opening standard duty stainless steel, quad formation cable cleat

Description

The CMP Saturn High Temperature is a quad composite cable cleat, designed and tested in accordance with IEC 61914. Manufactured from 316L Stainless Steel with high temperature resistant Low Smoke & Fume, Zero Halogen (LSF0H), Phosphorus free polymeric liners to protect the cable sheath. The cleat is designed to accept four cables of the same size, for example three phase power cables plus a neutral cable. The top opening is designed to fit more cleats installed side-by-side. Flexible materials allow a wide opening for easy cable installation and the cleat is easily formed around the cables for closure. A high temperature resistant polymer has been used for the liners, enabling the cable cleat to withstand temperatures of -60°C to +130°C during normal operation. The three M10 fixing clearance holes in the base allows versatility of fixing the cleat to the mounting structure.

Features

- Third party certified to IEC 61914, GOST-R

- 316L Stainless Steel

- Quad formation

- Short circuit rating of 152kA

- Operating temperature -60°C to +130°C

- Combined single (M10) or two bolt (M10) base fixing

Additional Information

| Certification | |

|---|---|

|

|

|

| Technical Specification | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Certificates

Product Selector

| Part Number | Cable Ø range take (mm) | Width (W) | Height (H) | Depth (D) | Hole Pitch (P) | Base Fixing Ø (D1) | Base Fixing Ø (D2) | Weight (g) | |

|---|---|---|---|---|---|---|---|---|---|

|

|

QSDSS016020HT | 16-20 | 63 | 87 | 58 | 1 x M10 | 300 | ||

|

|

QSDSS019023HT | 19-23 | 66 | 93 | 58 | 1 x M10 | 309 | ||

|

|

QSDSS021027HT | 21-27 | 73 | 101 | 58 | 1 x M10 | 334 | ||

|

|

QSDSS026031HT | 26-31 | 77 | 109 | 58 | 1 x M10 | 352 | ||

|

|

QSDSS030034HT | 30-34 | 80 | 115 | 58 | 1 x M10 | 354 | ||

|

|

QSDSS031035HT | 31-35 | 81 | 117 | 55 | 25 | 2 x M10 | 1 x M10 | 332 |

|

|

QSDSS033037HT | 33-37 | 84 | 121 | 55 | 25 | 2 x M10 | 1 x M10 | 338 |

|

|

QSDSS036040HT | 36-40 | 90 | 127 | 55 | 25 | 2 x M10 | 1 x M10 | 349 |

|

|

QSDSS039043HT | 39-43 | 96 | 133 | 55 | 25 | 2 x M10 | 1 x M10 | 360 |

|

|

QSDSS041045HT | 41-45 | 100 | 137 | 55 | 25 | 2 x M10 | 1 x M10 | 366 |

|

|

QSDSS044047HT | 44-47 | 104 | 140 | 55 | 25 | 2 x M10 | 1 x M10 | 374 |

|

|

QSDSS046051HT | 46-51 | 110 | 147 | 55 | 50 | 2 x M10 | 1 x M10 | 429 |

|

|

QSDSS049053HT | 49-53 | 116 | 153 | 55 | 50 | 2 x M10 | 1 x M10 | 438 |

|

|

QSDSS052056HT | 52-56 | 122 | 159 | 55 | 50 | 2 x M10 | 1 x M10 | 447 |

|

|

QSDSS055059HT | 55-59 | 128 | 165 | 55 | 50 | 2 x M10 | 1 x M10 | 456 |

|

|

QSDSS058062HT | 58-62 | 134 | 171 | 55 | 50 | 2 x M10 | 1 x M10 | 468 |

|

|

QSDSS061065HT | 61-65 | 140 | 177 | 55 | 50 | 2 x M10 | 1 x M10 | 478 |

|

|

QSDSS064068HT | 64-68 | 146 | 183 | 55 | 75 | 2 x M10 | 1 x M10 | 524 |

|

|

QSDSS067071HT | 67-71 | 152 | 189 | 55 | 75 | 2 x M10 | 1 x M10 | 533 |

Your Shortlist

Your Selection

"*" indicates required fields