CHDP2-X Cable Lug

ETIM Classification

EC001051

Heavy Duty Metric Copper Compression Cable Lug - Parallel Entry Standard Barrel with 2 Stud Holes - No Inspection Window

Description

These products have been designed and third party certified to IEC 61238-1 Class A, for high quality and reliable crimping. Manufactured from high purity, oxygen-free, seamless copper tube (C110/CW009A), these cable lugs are precisely dimensioned to achieve optimal crimping with suitable conductors. The lugs are annealed to enhance durability, minimising risk of fracture between the palm and barrel. The tin coating ensures corrosion and oxidation resistance, ensuring maximum efficiency of the connection. No inspection window to prevent moisture ingress for outdoor applications; inspection window can be added as an option - see data sheet CHDP2. The centres of the two stud holes are detailed in the dimensional table. Custom stud hole dimensions are available on request.

Features

- Stud hole centre dimensions standardised at 44.5 mm; bespoke pitch available on request

- Sizes to suit conductors as per EN 60228 cables; 25 mm² up to 630 mm²

- Third Party Certified to IEC 61238-1 Class A

- Manufactured from high purity (99.9%) copper seamless tube (BS EN 13600)

- Annealed and electrolytically tin plated for reliable crimping, with oxidation and corrosion resistance

- No inspection window to enhance ingress protection for outdoor applications

- Enhanced marking on the barrel for simple die selection, inspection and traceability

- CMP crimping die available for optimal crimping

- Bevelled entry to aid conductor insertion

- Sold in bags; product must be ordered in bag multiples. See table on following page for bag quantities

- Crimping die index numbers match CSA or wire size; refer to CMP compatible die chart for more information

Additional Information

| Certification | ||||

|---|---|---|---|---|

|

||||

| Technical Specification | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

Certificates

Product Selector

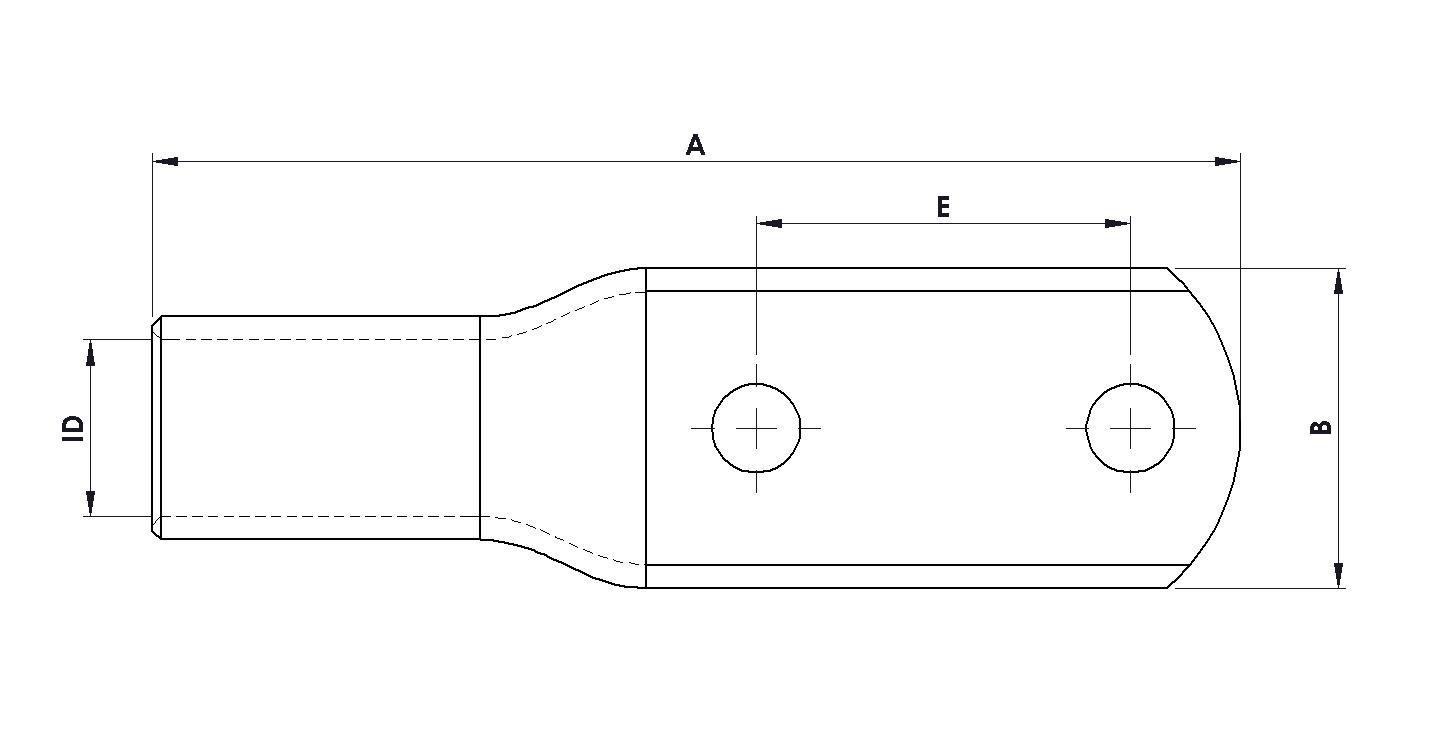

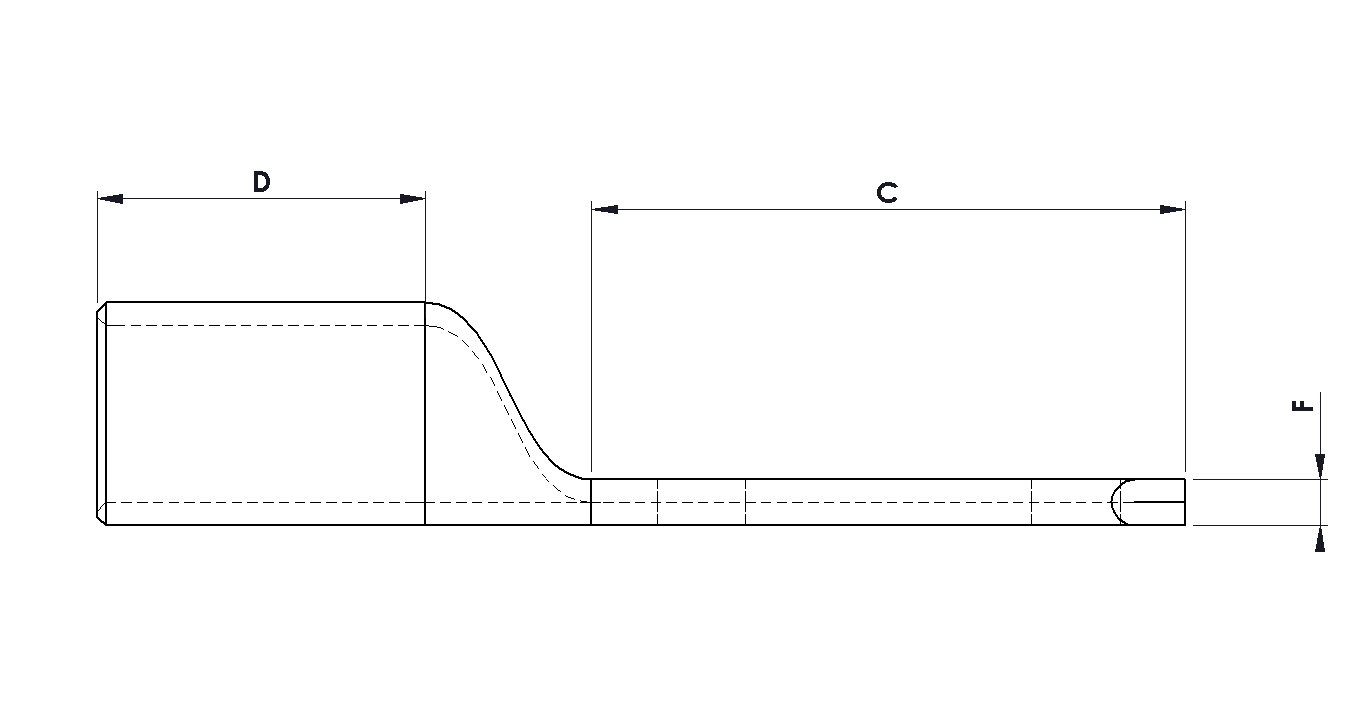

| Part Number | Cable Size (mm²) | Hole Stud Size | Die Index No. | Internal Diameter (ID) | Overall Length (A) | Palm Width (B) | Palm Length (C) | Barrel Length (D) | Stud Hole Distance (E) | Palm Thickness (F) | Stud Hole Spacing (G) | Pack Qty | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

025CHDP208X | 25 | M8 | 25H | 6.8 | 90.2 | 13 | 67.5 | 14 | 11.5 | 1.9 | 44.5 | 100 |

|

|

025CHDP210X | 25 | M10 | 25H | 6.8 | 93.2 | 14.5 | 70.5 | 14 | 13 | 1.7 | 44.5 | 100 |

|

|

025CHDP212X | 25 | M12 | 25H | 6.8 | 97.2 | 16.5 | 74.5 | 14 | 15 | 1.5 | 44.5 | 100 |

|

|

035CHDP208X | 35 | M8 | 35H | 8.2 | 90.9 | 15 | 67.5 | 14 | 11.5 | 2.4 | 44.5 | 100 |

|

|

035CHDP210X | 35 | M10 | 35H | 8.2 | 93.9 | 16 | 70.5 | 14 | 13 | 2.2 | 44.5 | 100 |

|

|

035CHDP212X | 35 | M12 | 35H | 8.2 | 99.4 | 21 | 74.5 | 15.5 | 15 | 1.7 | 44.5 | 100 |

|

|

050CHDP208X | 50 | M8 | 50H | 9.5 | 94.9 | 18 | 67.5 | 18 | 11.5 | 2.8 | 44.5 | 50 |

|

|

050CHDP210X | 50 | M10 | 50H | 9.5 | 97.9 | 18 | 70.5 | 18 | 13 | 2.8 | 44.5 | 50 |

|

|

050CHDP212X | 50 | M12 | 50H | 9.5 | 101.9 | 21 | 74.5 | 18 | 15 | 2.4 | 44.5 | 50 |

|

|

070CHDP208X | 70 | M8 | 70H | 11.2 | 98.8 | 21 | 67.5 | 20 | 11.5 | 3.4 | 44.5 | 50 |

|

|

070CHDP210X | 70 | M10 | 70H | 11.2 | 101.8 | 21 | 70.5 | 20 | 13 | 3.4 | 44.5 | 50 |

|

|

070CHDP212X | 70 | M12 | 70H | 11.2 | 105.8 | 21 | 74.5 | 20 | 15 | 3.4 | 44.5 | 50 |

|

|

070CHDP214X | 70 | M14 | 70H | 11.2 | 107.8 | 25 | 76.5 | 20 | 16 | 2.8 | 44.5 | 50 |

|

|

095CHDP210X | 95 | M10 | 95H | 13.5 | 105.1 | 25 | 70.5 | 22 | 13 | 3.8 | 44.5 | 20 |

|

|

095CHDP212X | 95 | M12 | 95H | 13.5 | 109 | 25 | 74.5 | 22 | 15 | 3.8 | 44.5 | 20 |

|

|

095CHDP214X | 95 | M14 | 95H | 13.5 | 111 | 26 | 76.5 | 22 | 16 | 3.6 | 44.5 | 20 |

|

|

095CHDP216X | 95 | M16 | 95H | 13.5 | 115 | 26 | 80.5 | 22 | 18 | 3.6 | 44.5 | 20 |

|

|

120CHDP210X | 120 | M10 | 120H | 15 | 112 | 28 | 70.5 | 24 | 13 | 4.2 | 44.5 | 20 |

|

|

120CHDP212X | 120 | M12 | 120H | 15 | 113.5 | 28 | 74.5 | 24 | 15 | 4.2 | 44.5 | 20 |

|

|

120CHDP214X | 120 | M14 | 120H | 15 | 115.5 | 28 | 76.5 | 24 | 16 | 4.2 | 44.5 | 20 |

|

|

120CHDP216X | 120 | M16 | 120H | 15 | 119.5 | 28 | 80.5 | 24 | 18 | 4.2 | 44.5 | 20 |

|

|

150CHDP210X | 150 | M10 | 150H | 16.5 | 115 | 30.5 | 70.5 | 29 | 13 | 4.6 | 44.5 | 15 |

|

|

150CHDP212X | 150 | M12 | 150H | 16.5 | 119 | 30.5 | 74.5 | 29 | 15 | 4.6 | 44.5 | 15 |

|

|

150CHDP214X | 150 | M14 | 150H | 16.5 | 121 | 30.5 | 76.5 | 29 | 16 | 4.6 | 44.5 | 15 |

|

|

150CHDP216X | 150 | M16 | 150H | 16.5 | 125.6 | 30.5 | 80.5 | 29 | 18 | 4.6 | 44.5 | 15 |

|

|

185CHDP210X | 185 | M10 | 185H | 18.5 | 121 | 34 | 70.5 | 34 | 13 | 4.9 | 44.5 | 15 |

|

|

185CHDP212X | 185 | M12 | 185H | 18.5 | 125 | 34 | 74.5 | 34 | 15 | 4.9 | 44.5 | 15 |

|

|

185CHDP214X | 185 | M14 | 185H | 18.5 | 126.5 | 34 | 76.5 | 34 | 16 | 4.9 | 44.5 | 15 |

|

|

185CHDP216X | 185 | M16 | 185H | 18.5 | 130.9 | 34 | 80.5 | 34 | 18 | 4.9 | 44.5 | 15 |

|

|

240CHDP210X | 240 | M10 | 240H | 21 | 129.2 | 38 | 70.5 | 39 | 13 | 5.4 | 44.5 | 5 |

|

|

240CHDP212X | 240 | M12 | 240H | 21 | 133.9 | 38 | 74.5 | 39 | 15 | 5.4 | 44.5 | 5 |

|

|

240CHDP214X | 240 | M14 | 240H | 21 | 135.9 | 38 | 76.5 | 39 | 16 | 5.4 | 44.5 | 5 |

|

|

240CHDP216X | 240 | M16 | 240H | 21 | 139.9 | 38 | 80.5 | 39 | 18 | 5.4 | 44.5 | 5 |

|

|

300CHDP210X | 300 | M10 | 300H | 23.5 | 136.9 | 43 | 70.5 | 44 | 13 | 6.4 | 44.5 | 5 |

|

|

300CHDP212X | 300 | M12 | 300H | 23.5 | 140.8 | 43 | 74.5 | 44 | 15 | 6.4 | 44.5 | 5 |

|

|

300CHDP214X | 300 | M14 | 300H | 23.5 | 142.8 | 43 | 76.5 | 44 | 16 | 6.4 | 44.5 | 5 |

|

|

300CHDP216X | 300 | M16 | 300H | 23.5 | 146.8 | 43 | 80.5 | 44 | 18 | 6.4 | 44.5 | 5 |

|

|

400CHDP210X | 400 | M10 | 400H | 26.8 | 142.4 | 50 | 70.5 | 47 | 13 | 7.7 | 44.5 | 5 |

|

|

400CHDP212X | 400 | M12 | 400H | 26.8 | 146.4 | 50 | 74.5 | 47 | 15 | 7.7 | 44.5 | 5 |

|

|

400CHDP214X | 400 | M14 | 400H | 26.8 | 148.4 | 50 | 76.5 | 47 | 16 | 7.7 | 44.5 | 5 |

|

|

400CHDP216X | 400 | M16 | 400H | 26.8 | 152.4 | 50 | 80.5 | 47 | 18 | 7.7 | 44.5 | 5 |

|

|

500CHDP212X | 500 | M12 | 500H | 30 | 160.8 | 55.5 | 80.5 | 52 | 18 | 8.8 | 44.5 | 1 |

|

|

500CHDP214X | 500 | M14 | 500H | 30 | 160.8 | 55.5 | 80.5 | 52 | 18 | 8.8 | 44.5 | 1 |

|

|

500CHDP216X | 500 | M16 | 500H | 30 | 160.8 | 55.5 | 80.5 | 52 | 18 | 8.8 | 44.5 | 1 |

|

|

630CHDP212X | 630 | M12 | 630H | 35 | 170.6 | 64.5 | 80.5 | 59 | 18 | 9.7 | 44.5 | 1 |

|

|

630CHDP216X | 630 | M16 | 630H | 35 | 170.6 | 64.5 | 80.5 | 59 | 18 | 9.7 | 44.5 | 1 |

Your Shortlist

Your Selection

"*" indicates required fields